4/12

2. USING THE DROPER VET

The Droper Vet is a medical device designed to pressurize flexible infusion bags containing all solutions

suitable for intravenous infusion for horses. The Droper Vet can be used with any type of mammal with

some adaptations if hanged on a standing animal, without any adaptations if on a lying animal.

The device is dimensioned in such a way as to be able to receive most infusion bags up to 1,000 ml

commercially available at the time of its introduction.

Under no circumstances may rigid or semi-rigid bottles be inserted into the device.

The safety instructions regarding the use of such bags must be known prior to use.

The infusion flow rate is entirely dependent on the pressure exerted and on the viscosity of the product

in question.

The Droper Vet works by pressurizing the liquid bags. This imposes specific use rules similar to these

used when using other infusion devices working under pressure, like the pressure cuffs.

Types of infusion lines:

Two types of lines can be accepted :

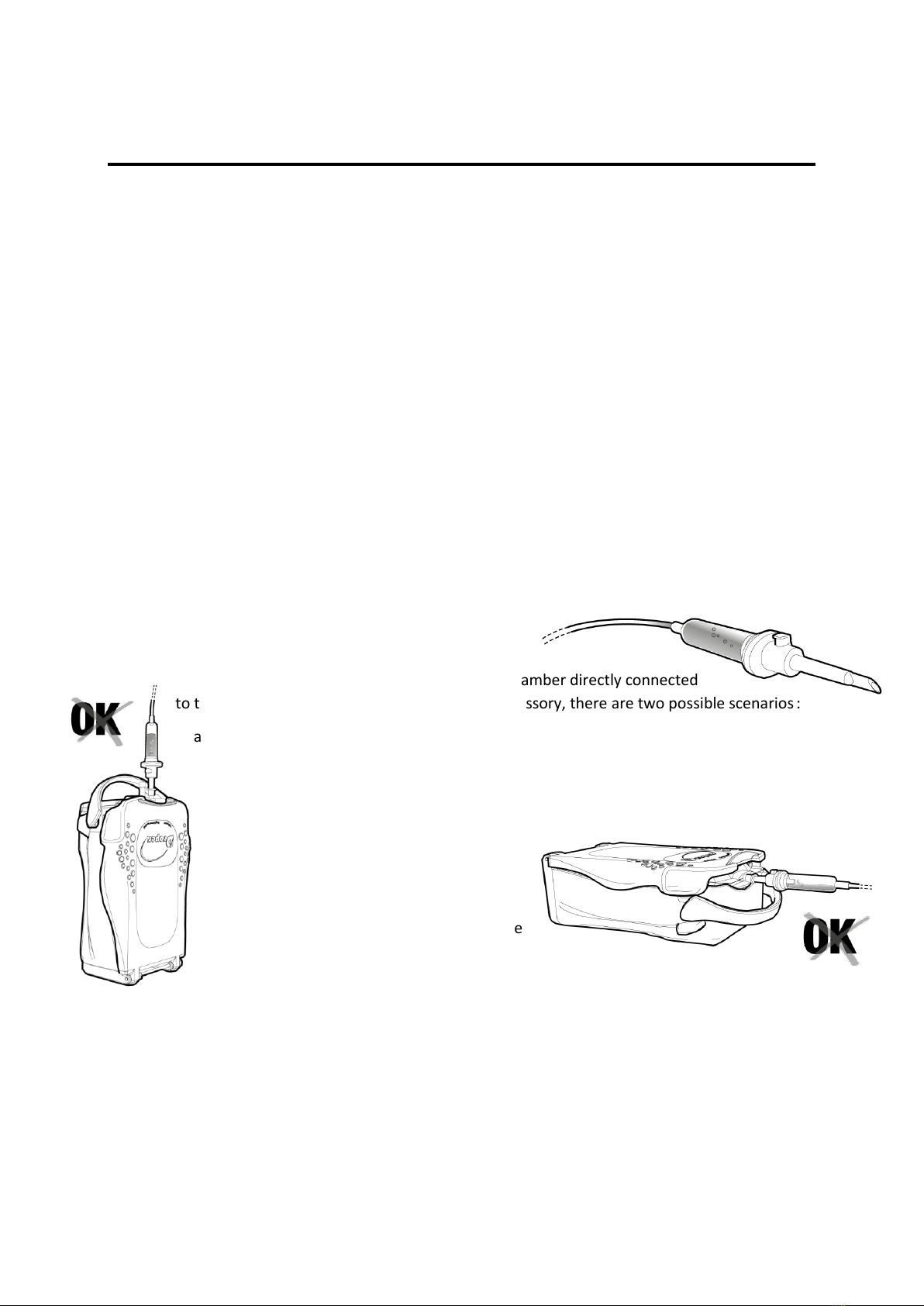

1. Classic infusion lines similar to these used with the

pressure cuffs. These lines have normally a drip chamber directly connected

to the spike (see attached drawing). With this accessory, there are two possible scenarios:

a. Droper used residentially with flow rate monitored through the drip chamber count –

Possible with any type and ant size of colloids or crystalloids flexible bags up to 1000

ml, –Classical air line purge :the drip chamber MUST stay in a vertical position, end

side down. In fact, in case this drip chamber would turn into an horizontal position

(see aside drawing) or worst into a vertical

position with the drip chamber end side up

(see aside drawing), the air volume

entrapped in the drip chamber would be

pushed towards the patient through the

infusion line.

If necessary, the Droper Vet can be hanged vertically by the mean of the hanging

ring being on the Droper Vet rear side, while making sure there is a sufficient free

height to allow the drip chamber to stay vertical.