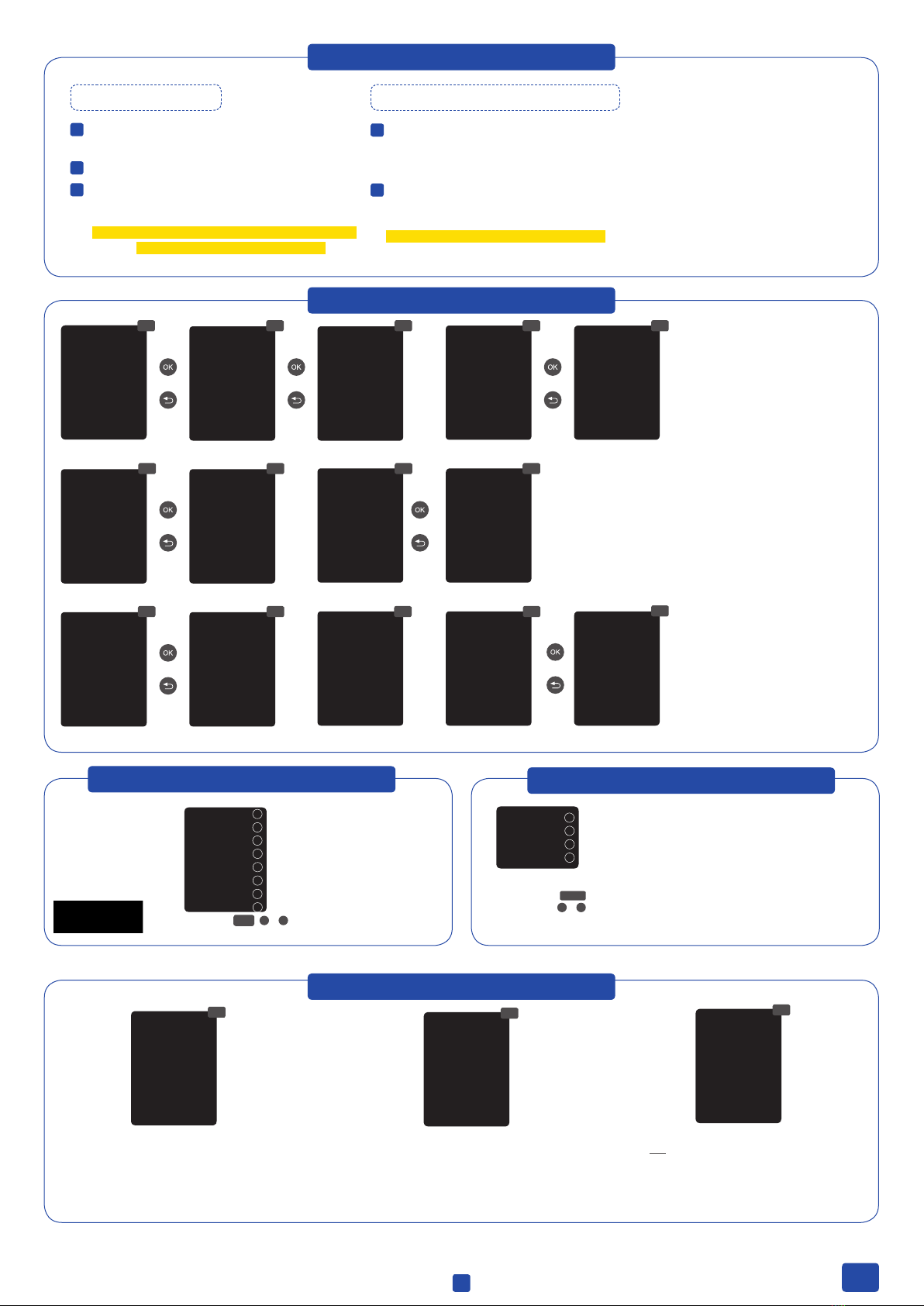

AUX 2 5& 6

Automatic

backwash valve

(Besgo)

AUX 1 3& 4

APF®dosing pump

18.3

18.6

18.4 18.5

18.7

18. AUXILIARY RELAYS

18.218.1

ACO®

11 & 12

110-230 V max. 3.15 A DRY CONTACT

1 2 3456 78910 11 12 13 14

AUX 4

Heating control

13 & 14

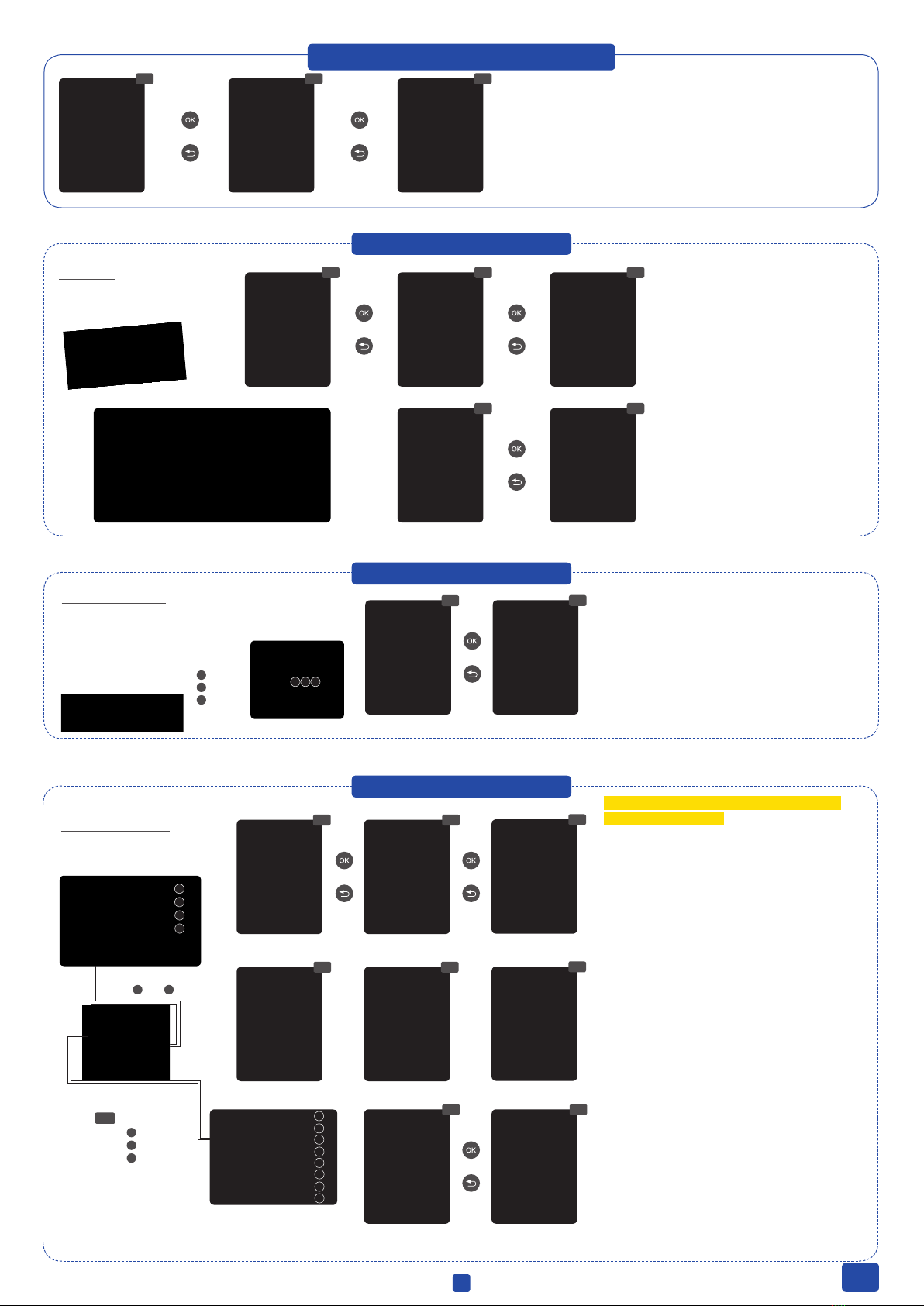

18.2 It is possible to control up to 4 extra auxiliary

relays (water attractions, dosing pumps, etc).

In default setting you will only see two available

relays: APF® and ACO®: (AUX 1 and 3). AUX 2 is

reserved for the Besgo Valve and AUX 4 for the

heating and therefore not shown here. If you do

not have a heating, you can deactivate it (Chapter

C & D in the service manual) and you will get a

additional free relay (AUX4).

18.3 Manual mode (ON/OFF).

18.4 Automatic mode: ON/OFF according to a timer that adjusts the start and

end of the program. The timers can be congured with a frequency.

18.5 Timer mode: Working time is programmed in minutes. Each time

the Shortcut on the front panel is pressed, it will start up and run for the

programmed time. This function is recommended for timing of air pumps of

spas.

18.7 Rename relays: It is posible to rename each auxiliary relay to suit the use

you want to assign. By pressing the plus/minus keys, a pop-up keyboard will

appear. Scroll up and down with the up/down keys and left to right with the

plus/minus keys. To select a letter press the OK.

The auxiliary relays are congured by default.

If you want to reassign the relays for other

accessories, you must access the “Service

Menu”.

Contact your authorised installer.

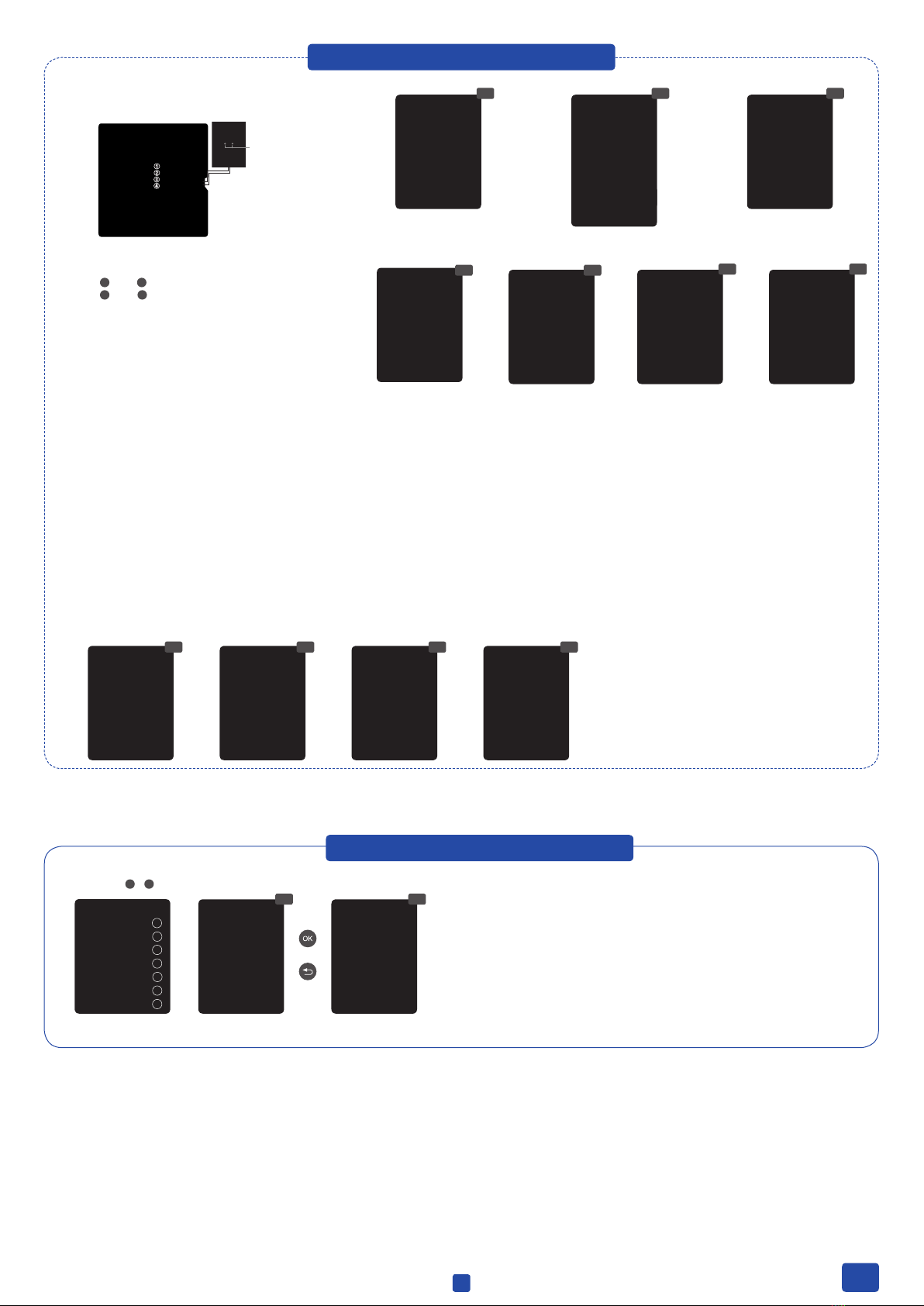

19. MAINTENANCE

If necessary, carry out a monthly visual inspection. To clean the cell:

Stop the system and close the valves

Place the cell for no more than 10 minutes in 3% hydrochloric acid or put it for 2 to 4 hours in normal vinegar.

Once the incrustations have softened remove with a hose to complete cleaning the cell.

DO NOT USE METALLIC OR SHARP OBJECTS TO REMOVE INCRUSTATIONS. Scratching the edges or surface of the cell will make it

vulnerable to chemicals, deteriorate the cell and invalidate the guarantee.

The pool must be vacuumed as usual and the skimmers emptied whenever necessary.

FILTER BACKWASHING: At least once every week for 4 to 5 minutes.

VERY IMPORTANT: Make sure the cell is off while cleaning the lter. If the system controls the ltration pump, use the option “backwash” of the programmed ltration

mode. See chapter 13 - automatic backwash

Check regularly the level of your pH and APF®bottle to prevent the dosing pump from running dry.

pH / Redox / Conductivity – probes: The probes must be cleaned and recalibrated every 2 to 3 months. To clean the probe insert in

electrode cleaner. After each clean the probes must be re-calibrated.

Attention: the probes should never dry out and must be kept wet if stored (when emptying the pool for winterising, make sure

to store the probe head in water).

~1200 ppm TDS/mS

~2000 μS

Visual inspection to detect incrustations.

SALT CONCENTRATION: HYDROLYSIS CELL:

1

1

2

2

3

3

4

Cleaning the Cell

General maintenance

Monthly checks

8EN