Table of Contents

1. Introduction .................................................................................................................................. 3

1.1. General safety instructions .................................................................................................. 3

1.2. General standards to be observed ....................................................................................... 3

1.2.1. Photovoltaic solar standards .................................................................................... 3

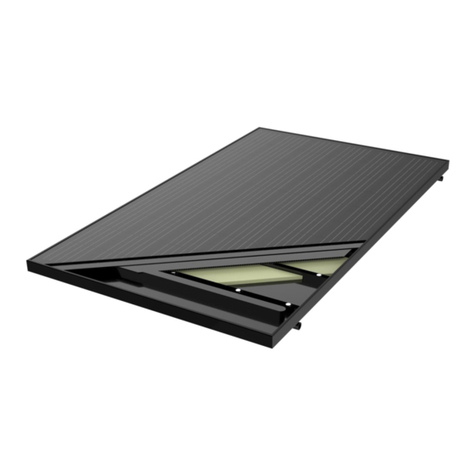

2. General description ....................................................................................................................... 5

2.1. Technical characteristics ..................................................................................................... 5

2.2. General recommendations .................................................................................................. 5

2.2.1. Handling ................................................................................................................. 5

2.2.2. Transport ................................................................................................................ 5

2.2.3. Storage ................................................................................................................... 5

2.3. Technical considerations ..................................................................................................... 5

2.3.1. Static roofing requirements ...................................................................................... 6

2.3.2. Angle of inclination .................................................................................................. 6

2.3.3. Wind and snow load ................................................................................................ 6

2.3.4. System location ....................................................................................................... 6

2.3.5. Types of mounting ................................................................................................... 7

2.3.6. Protection against fire / explosion ............................................................................. 7

3. Mechanical installation .................................................................................................................. 8

3.1. Installing DualSun modules ................................................................................................. 8

3.2. Assembly specifications .................................................................................................... 10

3.2.1. Installation areas on the rails of the mounting system .............................................. 10

4. Electrical Installation .................................................................................................................... 11

4.1. Electrical connection .......................................................................................................... 11

4.2. Electrical fittings, cables and diodes .................................................................................. 12

4.3. Grounding and lightning protection .................................................................................... 14

4.4. Indirect lightning strike ...................................................................................................... 14

5. Cleaning the surface of the modules ............................................................................................. 16

6. Decommissioning of the installation .............................................................................................. 17

6.1. Removing a module ......................................................................................................... 17

6.2. Waste treatment ............................................................................................................... 17

7. Responsibilities ........................................................................................................................... 18

7.1. Guarantee conditions ....................................................................................................... 18

7.2. Disclaimer ........................................................................................................................ 18

Installation, use, maintenance manual DualSun FLASH

2