ISO 9001: 2015

TCDS EASA: EASA P.038

Part 21G EASA: FR.21G.0273

3/27

Summary

1. Presentation of the Certified FLASH-R propeller.......................................................................................................4

Description ........................................................................................................................................................41.1.

Characteristics..................................................................................................................................................41.2.

Shielding leading edge in Inconel®....................................................................................................................51.3.

Accessories.......................................................................................................................................................51.4.

Sales references ...............................................................................................................................................51.5.

2. Applications................................................................................................................................................................6

3. Installation precautions..............................................................................................................................................6

4. Components of the Certified FLASH-R......................................................................................................................7

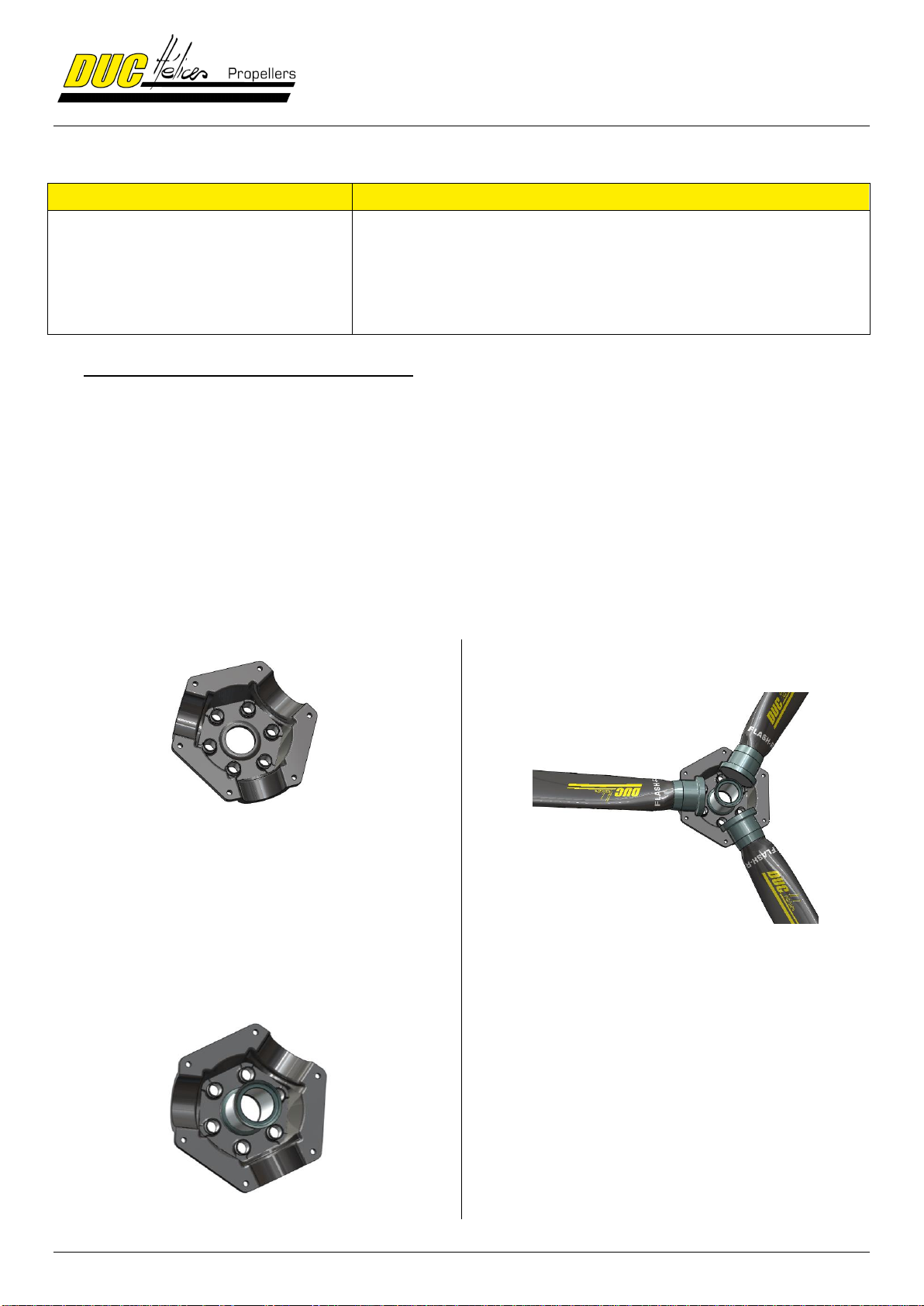

Mounting configuration of the FLASH-R propeller............................................................................................74.1.

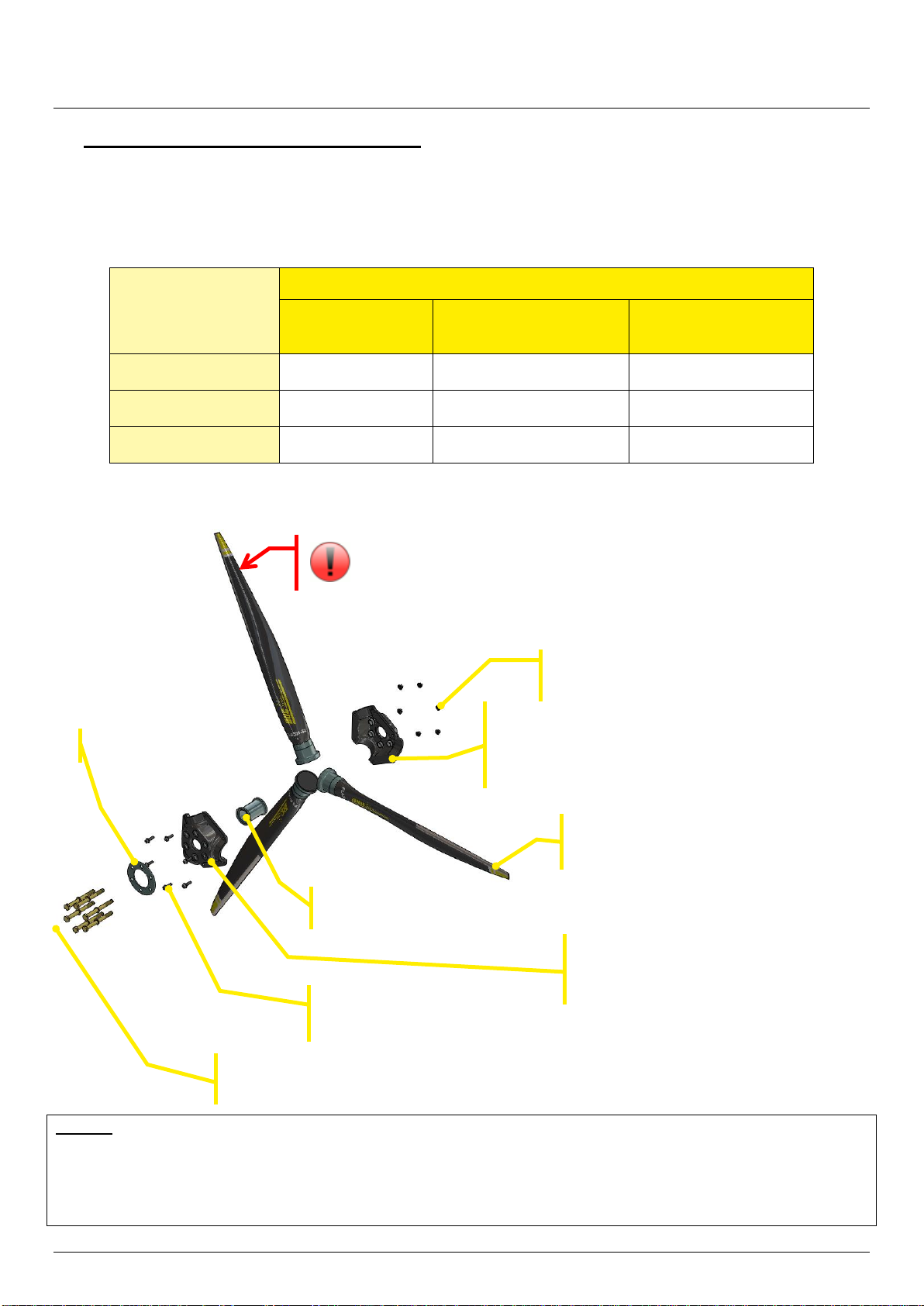

Exploded view for propeller...............................................................................................................................74.2.

List of components............................................................................................................................................84.3.

List of required tools........................................................................................................................................104.4.

5. Assembly instruction of the propeller.......................................................................................................................10

Assembly of the propeller................................................................................................................................105.1.

Installation on the aircraft................................................................................................................................125.2.

Setting of the propeller & Finalization of the installation.................................................................................155.3.

6. Precautions..............................................................................................................................................................18

7. Continuing airworthiness .........................................................................................................................................19

Airworthiness limitations..................................................................................................................................197.1.

Schedule of propeller check............................................................................................................................197.2.

Regular maintenance (by the user).................................................................................................................207.3.

Maintenance of 100 hours or yearly maintenance..........................................................................................217.4.

Impact location on the blade carbon surface ..................................................................................................227.5.

8. General terms of sale...............................................................................................................................................23

Ordering procedure.........................................................................................................................................238.1.

Delivery ...........................................................................................................................................................238.2.

Price ................................................................................................................................................................238.3.

Right of withdrawal..........................................................................................................................................238.4.

Warranties.......................................................................................................................................................23

8.5.

Privacy Policy..................................................................................................................................................238.6.

Litigation..........................................................................................................................................................238.7.

9. Annexes...................................................................................................................................................................24

Dimension of the engine propeller-shaft .........................................................................................................249.1.

912H spacer –Table screw length vs. Spacer thickness .......................................Erreur ! Signet non défini.9.2.

Airfoil ...............................................................................................................................................................259.3.