4/24

Summary

1. Presentation of the SWIRL-2 propeller......................................................................................................................5

1.1. Description ........................................................................................................................................................5

1.2. Characteristics..................................................................................................................................................5

1.3. Shielding leading edge in Inconel .....................................................................................................................6

1.4. Accessories......................................................................................................................................................6

1.1. Sales reference.................................................................................................................................................6

2. Applications................................................................................................................................................................7

3. Installation precautions..............................................................................................................................................7

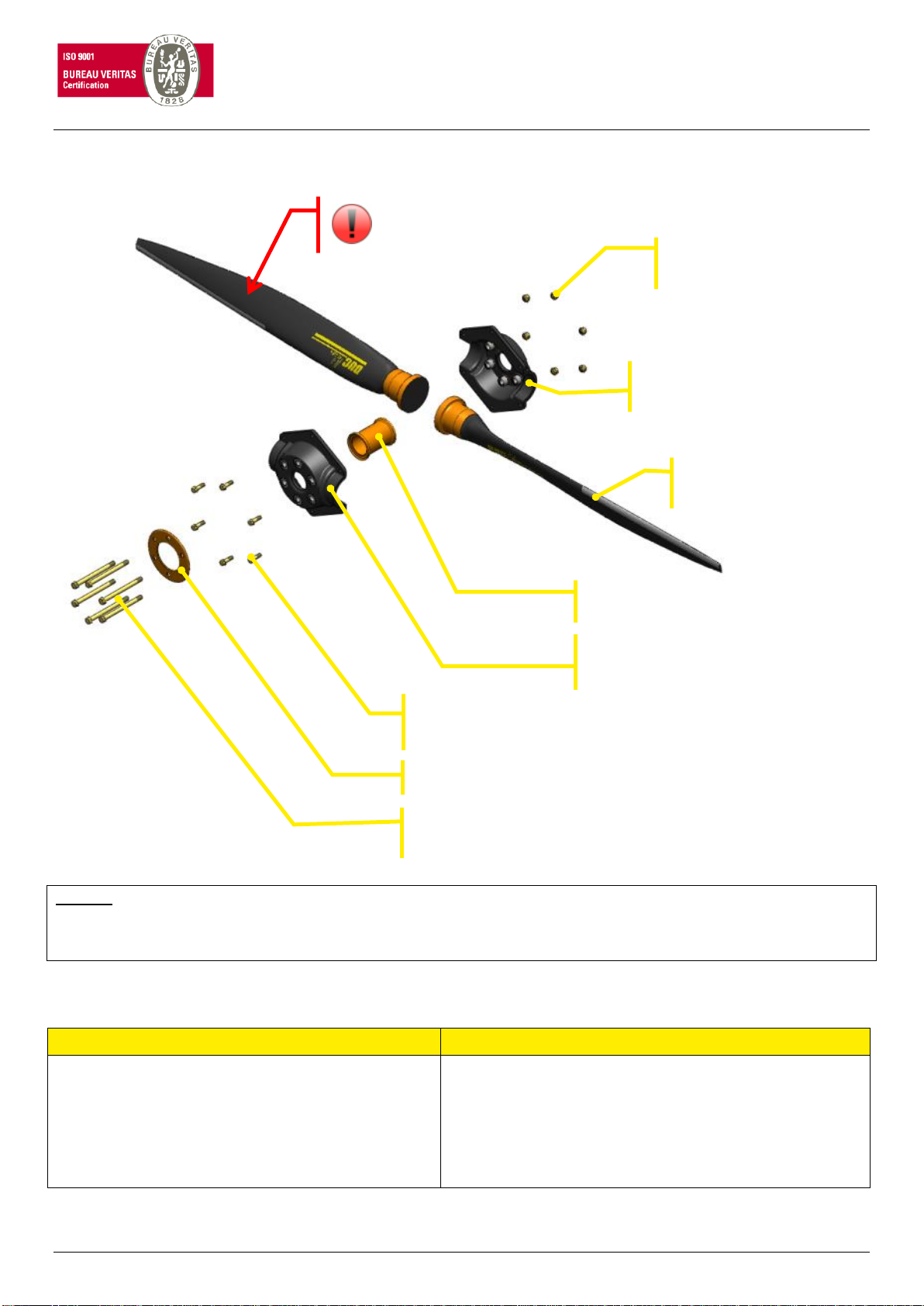

4. Components of the SWIRL-2 propellers....................................................................................................................8

4.1. Mounting configuration of the SWIRL-2 propellers...........................................................................................8

4.2. Mounting screws ...............................................................................................................................................8

4.3. Exploded view for propeller...............................................................................................................................9

4.4. List of required tools..........................................................................................................................................9

5. Assembly instruction of the propeller.......................................................................................................................10

5.1. Assembly of the propeller................................................................................................................................10

5.2. Installation on the aircraft................................................................................................................................11

5.3. Setting of the propeller & Finalization of the installation.................................................................................14

6. Precautions..............................................................................................................................................................17

7. Indications for testing...............................................................................................................................................17

8. Installation without spinner or with spinner other than DUC....................................................................................18

9. Potential use & Propeller maintenance....................................................................................................................18

9.1. Potential use of the propeller: Unlimited .........................................................................................................18

9.2. Propeller maintenance schedule.....................................................................................................................18

9.1. Regular maintenance (by the user).................................................................................................................19

9.2. General maintenance (by the user or an aeronautics workshop)...................................................................19

9.3. Complete maintenance (by DUC Hélices) ......................................................................................................20

10. General terms of sale...............................................................................................................................................20

10.1. Ordering procedure.........................................................................................................................................20

10.2. Delivery ...........................................................................................................................................................20

10.3. Price ................................................................................................................................................................20

10.4. Right of withdrawal..........................................................................................................................................20

10.5. Warranties.......................................................................................................................................................20

10.6. Privacy Policy..................................................................................................................................................20

10.7. Litigation..........................................................................................................................................................20

11. Annexes...................................................................................................................................................................21

11.1. Dimension of the engine propeller-shaft .........................................................................................................21

11.2. Airfoil ...............................................................................................................................................................22

11.3. Moment of inertia of the SWIRL-2 propeller....................................................................................................22

11.4. Operating limitation of the SWIRL-2 propeller ................................................................................................22

11.5. Identification marking of the propeller.............................................................................................................22

11.6. Declaration of conformance of the SWIRL-2 propellers..................................................................................23