DCH Users Manual

U

◇Install a circuit breaker or protecting instrument in the exterior circuit. For safety, the

controller should be fixedly mounted, and the cable should be put in the pipe.

1.3 Warning of installment

◇Never install it on combustible devices. Never put the combustible things beside it. Never

install it in the surrounding which has volatile gas, dust, point-blank sunshine, high

temperature or humidity. Never drop any metal into the controller.

◇Do not disassemble or install the present control by yourself, please reach for the

professional engineer.

◇Please make sure the power line in well condition. If it is damaged or pressed by heavier

goods, it might cause electricity leakage or fire accident.

◇Please make sure the controller is fixedly mounted in the assembly hole to prevent

damage.

◇Keep the control a suitable distance from other instrument.

◇Install a masking means to isolate static electricity, noise signals, magnetic field or

radiation to prevent operation failure.

1.4 Attention of connection design

◇We suggest that you use the DC24V/1A power source. Separate the input & output power

supply from system power supply.

◇Do not put the controller to earth at the same point with motor and transducer. You should

put it in another line. Please ensure that the controller and the press are well earthed.

◇Please install filters at heavy load terminal and inductive terminal to avoid the controller

from being jammed. Please add resistance and capacitance devices to AC contactor and

solenoid valve. The resistance takes 22Ω/2W, the capacitance takes 0.1μF/3KV. Install the

absorb equipment at the side near the contactor coil or the valve coil.

◇The controller cable should as short as possible. Do not put it together with the high

pressure electricity. If it is difficult for you please use metal hose to separate them and put

the AC and DC to earth dividually.

Attention: Putting the sensor wire to earth is extremely important. Please ensure that the

shielded wire of sensor connect wire is well earthed.

3

II Function And Specification

2.1 Function list

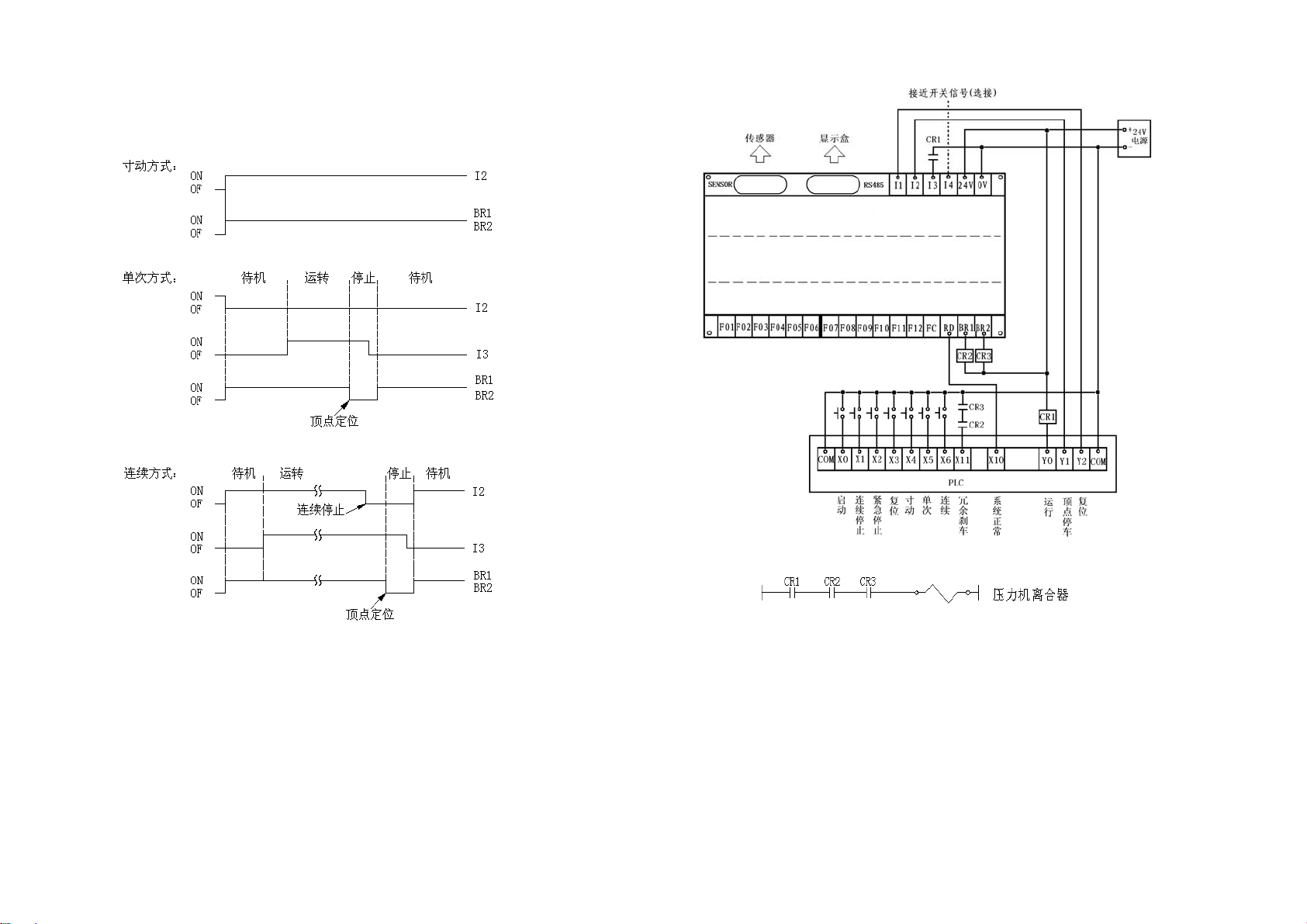

SPM/Angle Display: Continuous mode, showing the value of SPM when SPM>8,

otherwise showing the angle. Other mode, showing the angle.

Production value display: 6 digits. The max. is 999999.

★Brake signal:2 ways redundancy output.

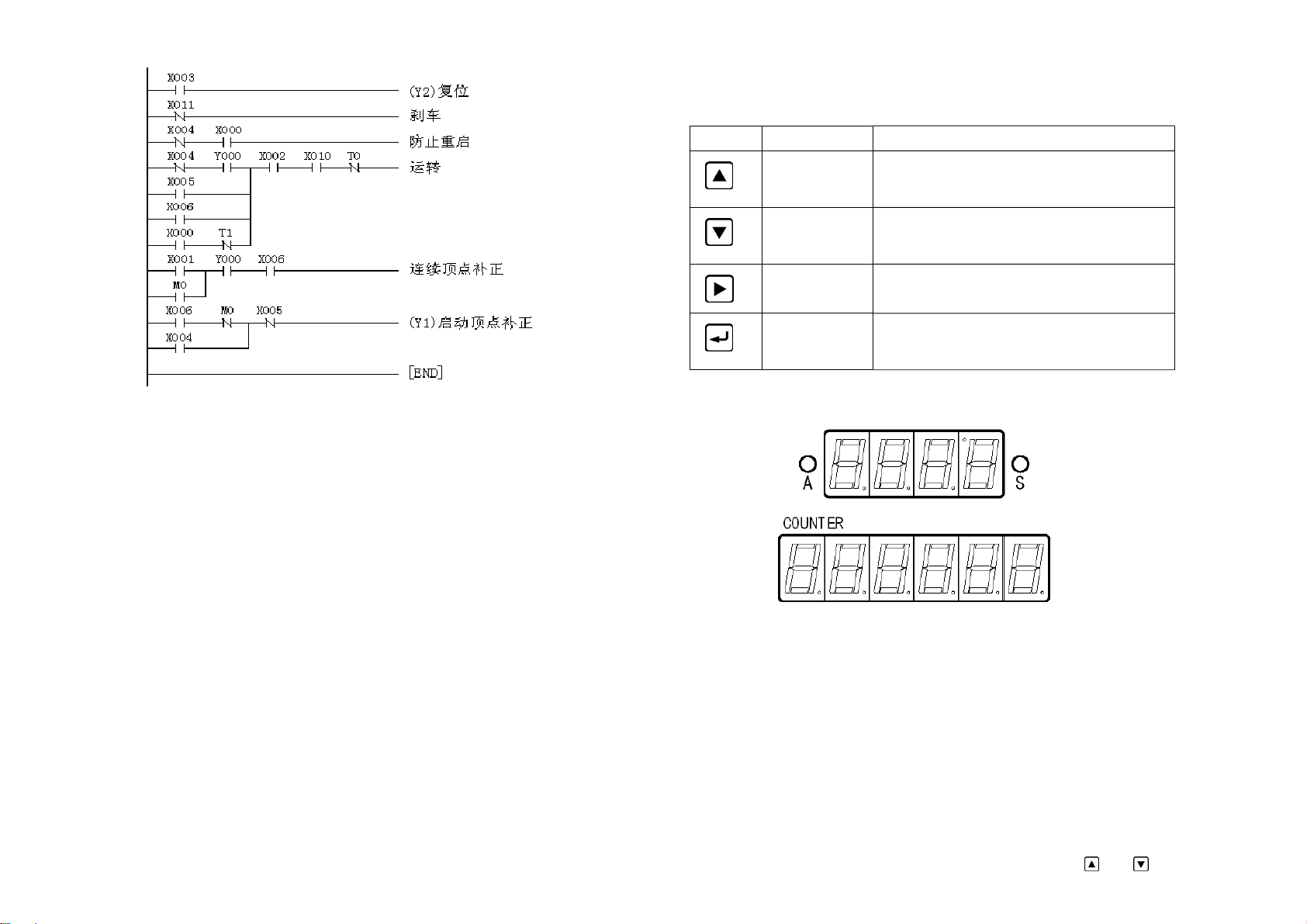

Top point locate:Automatically compensate the warp when positioning the Top

dead end Point.

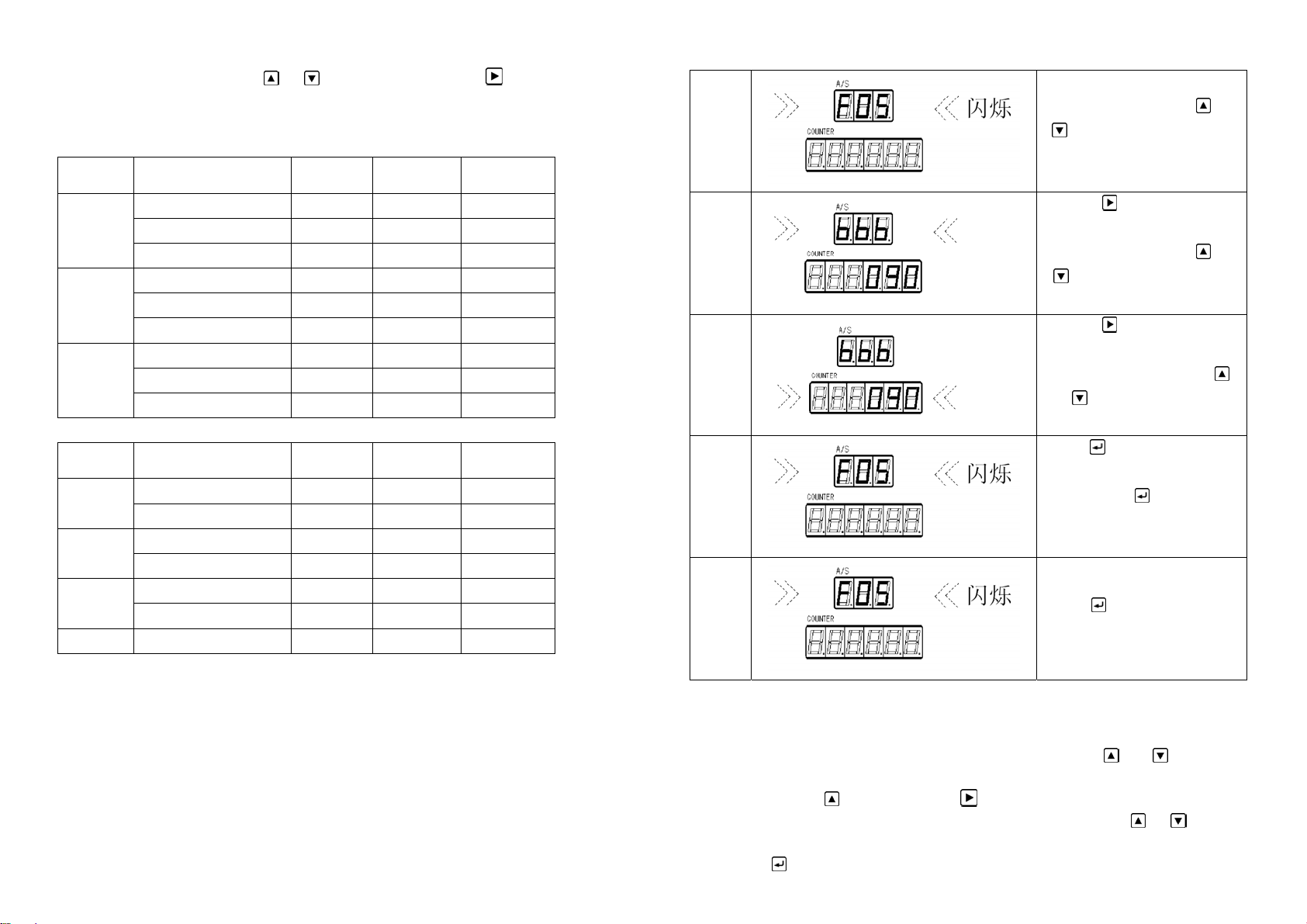

Cam Setting:Programmable cam output 6 channels; Programmable cam

output 6 channels.

Production value has 1 channel output.

Bottom Dead Point(180°) Setting.

Forwards/Backwards running of the Angle Sensor Setting.

★Protection Function:locked protection,power off protection.

Software lock protection for system parameter

System unusual alarm.

Communication: Standard RS-485 bus communication connection

2.2Specification Table

Item Specification

Power Supply DC: 10~30V, 1A

OperationTemperature 0~40℃

Keeping Temperature -20~70℃30~85%

Angle Display 0~359º

Angle Setting 0~359º

Stroke 0~800 stroke/minute (360P/R)

Angle Sensor 1°

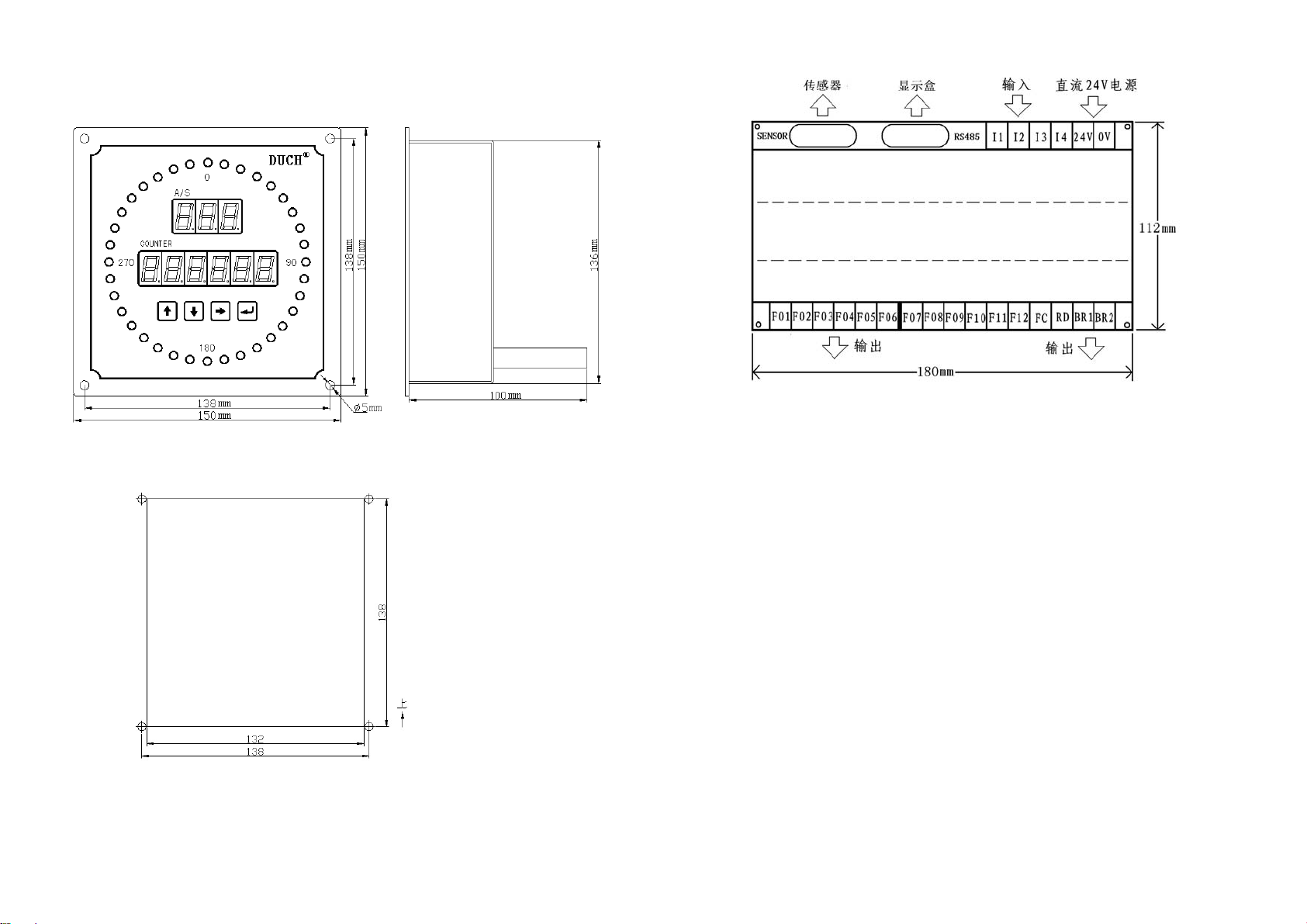

Indicating lamp Angle position indicating lamp 36

Display Angle/Speed(*1channel with 3 orders)

Counter(*1 channel with 6 orders)

Setting Key 4 micro switch keys(up, down, put in, enter)

Cam Output 0~359º, programmable scissors cam outputs are 6 channels,

programmable cam outputs are 9 channels.

Cam input 4 channels,DC24V±10%, ,Max. input current 5mA or dry

connect point input.

Output 16channels, collector through way output, max. fill current is

100mA

4