Clean the sealing face of

the valve body that is

located in the bottom

of the cistern

2

Carefully clean the outlet valve

seal under cold running water

Important:

Take care not to damage the seal

1

Niagara outlet valve maintenance

Filter Assembly

Filter

Clean the diaphragm and filter

assy under cold running water

3

2Remove filter assembly

using filter removal tool

Diaphragm

Float Assembly

Front Nut Carefully remove front nut,

pressure chamber and

diaphragm

1

Hydroflo inlet valve maintenance

Remove the Niagara valve through the service aperture

6

Twist the Niagara valve anti-clockwise to release

5

Remove the Hydroflo valve through the service aperture

4

Remove the Hydroflo valve from mounting clip

3

Close

90°

Close isolation valve and flush to empty cistern

2

Pull here to remove

PULL

Remove front service cover

1

Removal of internal components

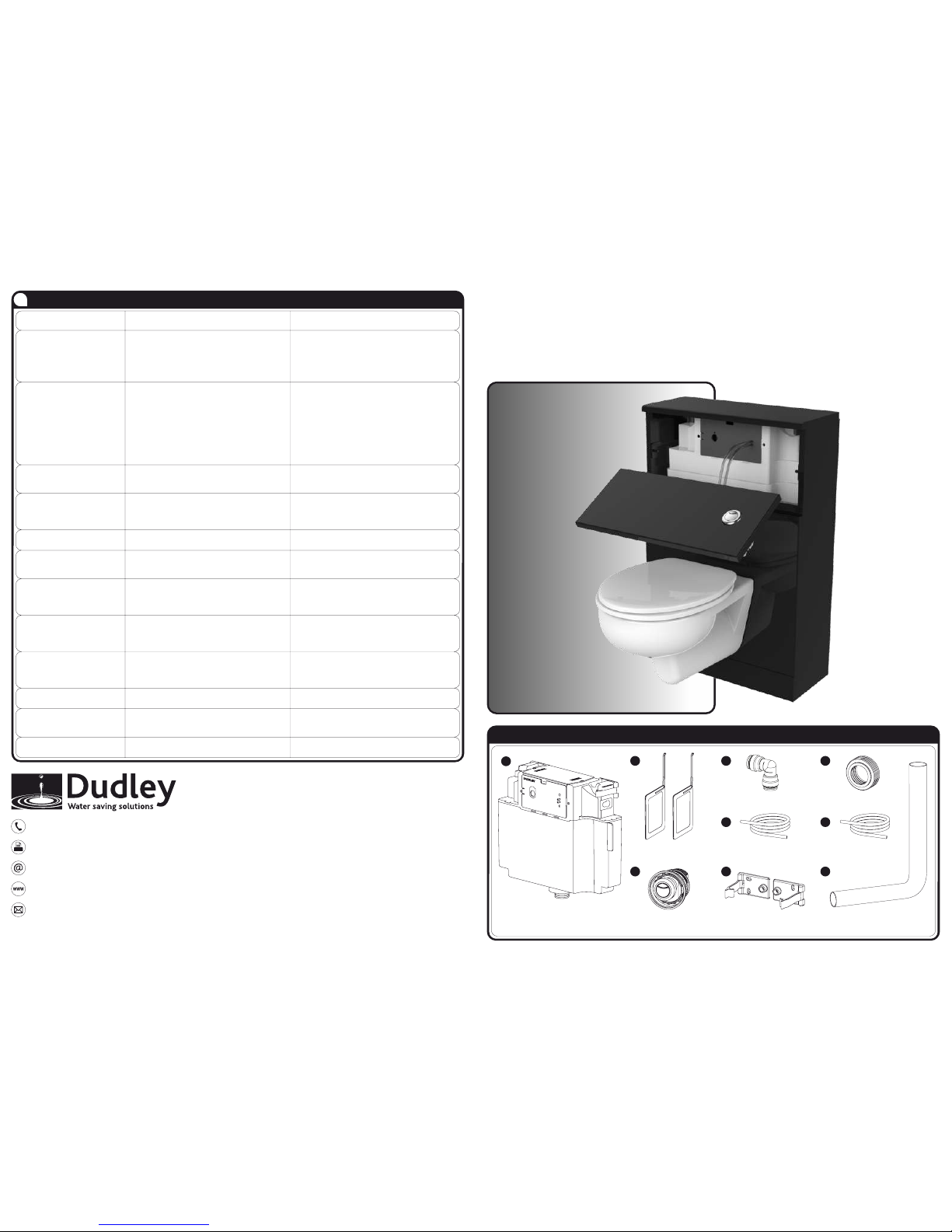

2VANTAGE CISTERN MAINTENANCE

Technical Help @ Thomas Dudley Ltd on 0121 530 7000

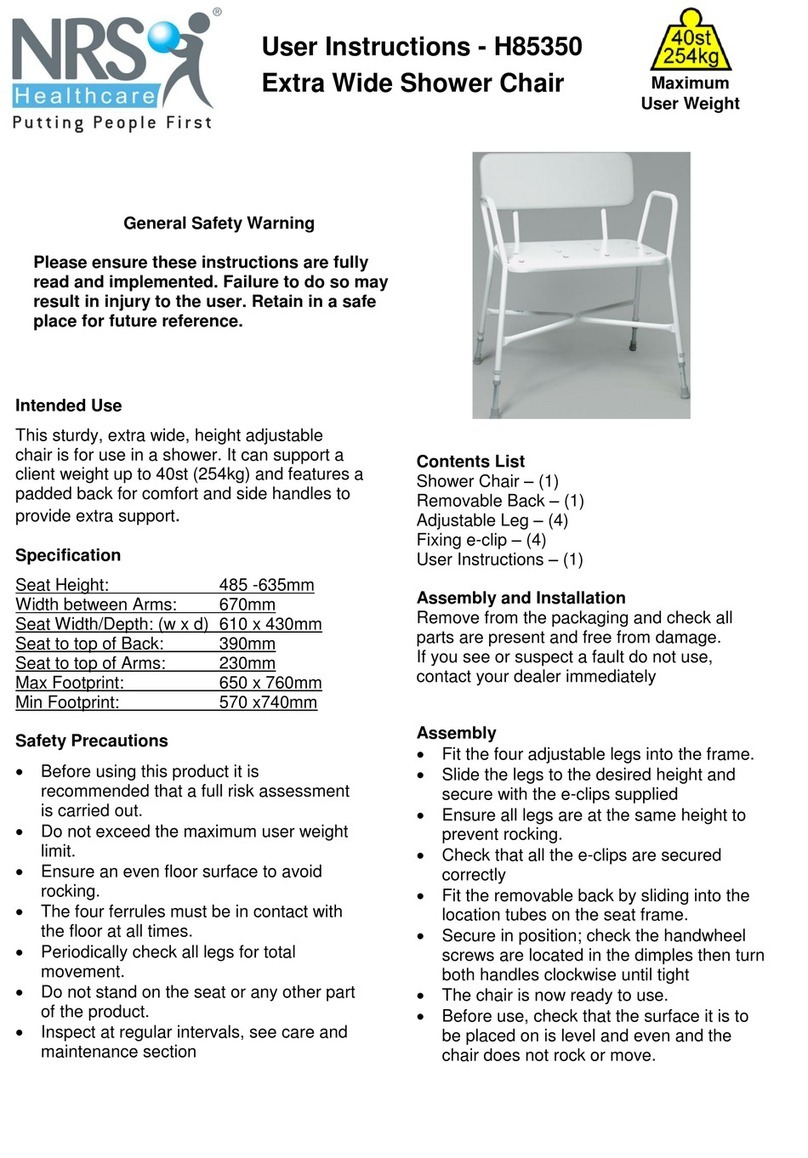

FINAL INSTALLATION CHECK LIST:

Check all moving components operate freely and the inlet valve shuts off correctly.

If overflowing or poor flushing subsequently occurs, check that the float and arm move freely up and down and that the water level is correct.

Check all joints are tightened correctly.

Check carefully for leaks.

Hold the inlet valve float down, causing the cistern to internally overflow. Ensure the overflow pipe is capable of discharging all incoming water

without the cistern overflowing. If water overflows the cistern make sure that the flow restrictor is fitted. If overflowing persists contact:

WARNING: No sealing compound, paste, flux or solvent to be used in contact with plastic or rubber surfaces to avoid damage. Rubber washers

or ‘O’ rings should provide an adequate seal. PTFE tape may be used on threads. Do not over tighten plastic nuts.

No chemical block or additive is to be used in this cistern.

Level 3: 6/4L Dual flush

Level 5: 5/3.3L Dual flush

Level 10: 4/2.6L Dual flush

Slide to required level and

relock into position

Twist adjustable weight

anti-clockwise to unlock

Adjust weight

Reverse operation to re-fit

Twist Niagara valve

anti-clockwise to release

from Vantage cistern

Remove Niagara Valve

Configure Niagara valve

2

Mono Flush

6 Litre - No Partitions

5 Litre - One Partition

4 Litre - Two Partitions

Dual Flush

6/4 Litre - No Partitions

5/3 Litre - One Partition

4/2.6 Litre - Two Partitions

Fit or remove partitions as required

1

Converting the Vantage cistern flush capacity (if required)

Check water level and adjust if

necessary by rotating float

adjuster stem

4

Water

Level Set chamber

to lowest

position

Open

90°

Open isolation valve

(factory set to closed)

Note: Bottom entry cisterns

require an external isolation

valve (not supplied)

3

Push-fit the elbow and

connect the mains supply

2

Remove factory fitted flow restrictor

if necessary (See table above)

1

Connect inlet and check water level

Trim

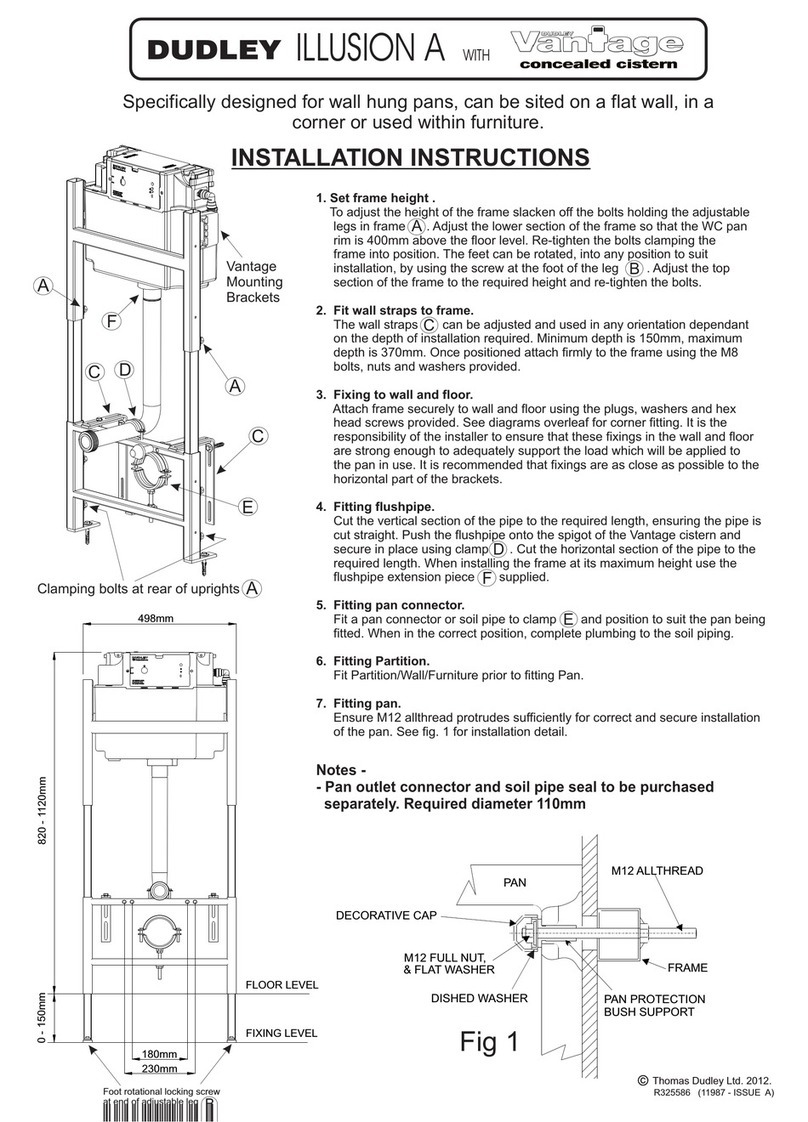

Trim horizontal section of flush

pipe to suit WC pan installation.

Re-fit flush pipe to Vantage

cistern and connect to WC pan

3

Distance A

Cut Line

Cut Distance A from larger

diameter section of flush pipe

2

328mm MAX

70mm MIN

740mm MAX

440mm MIN

Distance A

Fit flush pipe to Vantage cistern and measure Distance A

1

Fit flush pipe

Fit the mounting brackets and secure the

cistern to the wall (screws not supplied)

2

TEMPLATE

Use provided hole guide to mark and drill holes

to suit No.8 CSK screws ensuring template is level

(Guide located on front flap of box)

1

Fit Vantage cistern to wall

Note: Prior to installation ensure there is sufficient space

for the Vantage to be installed

1VANTAGE CISTERN INSTALLATION