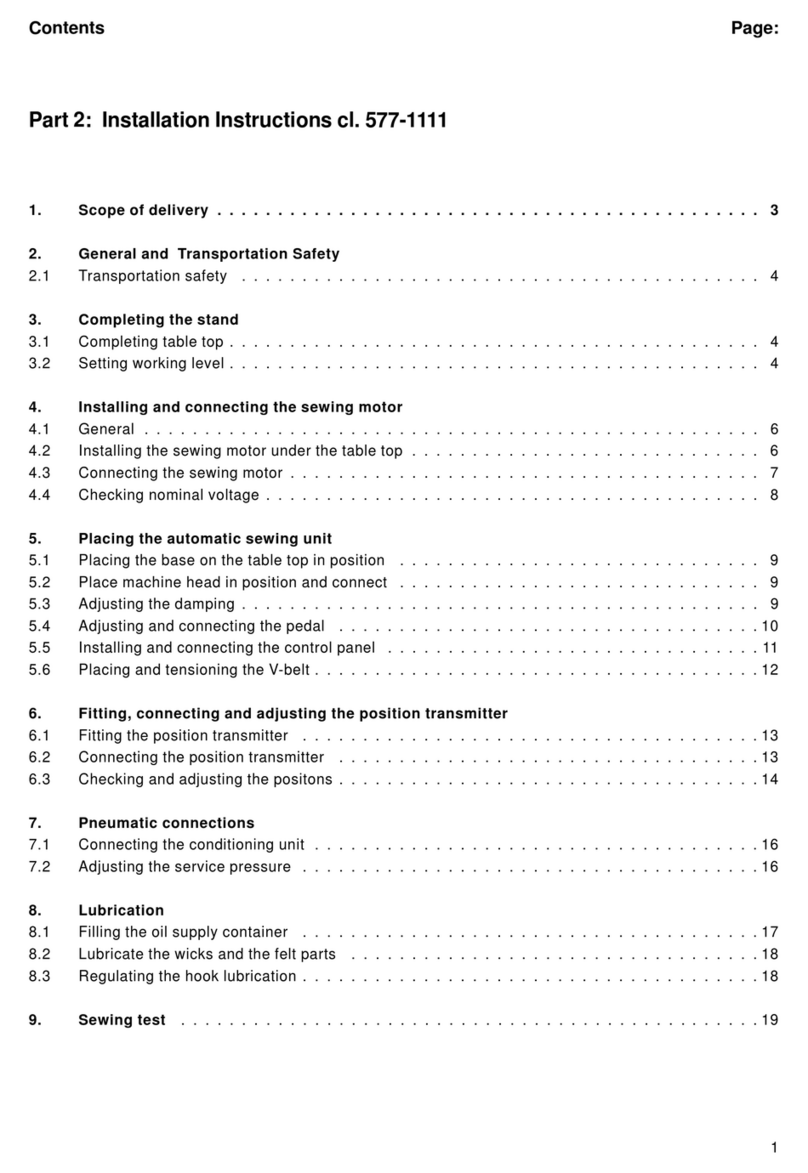

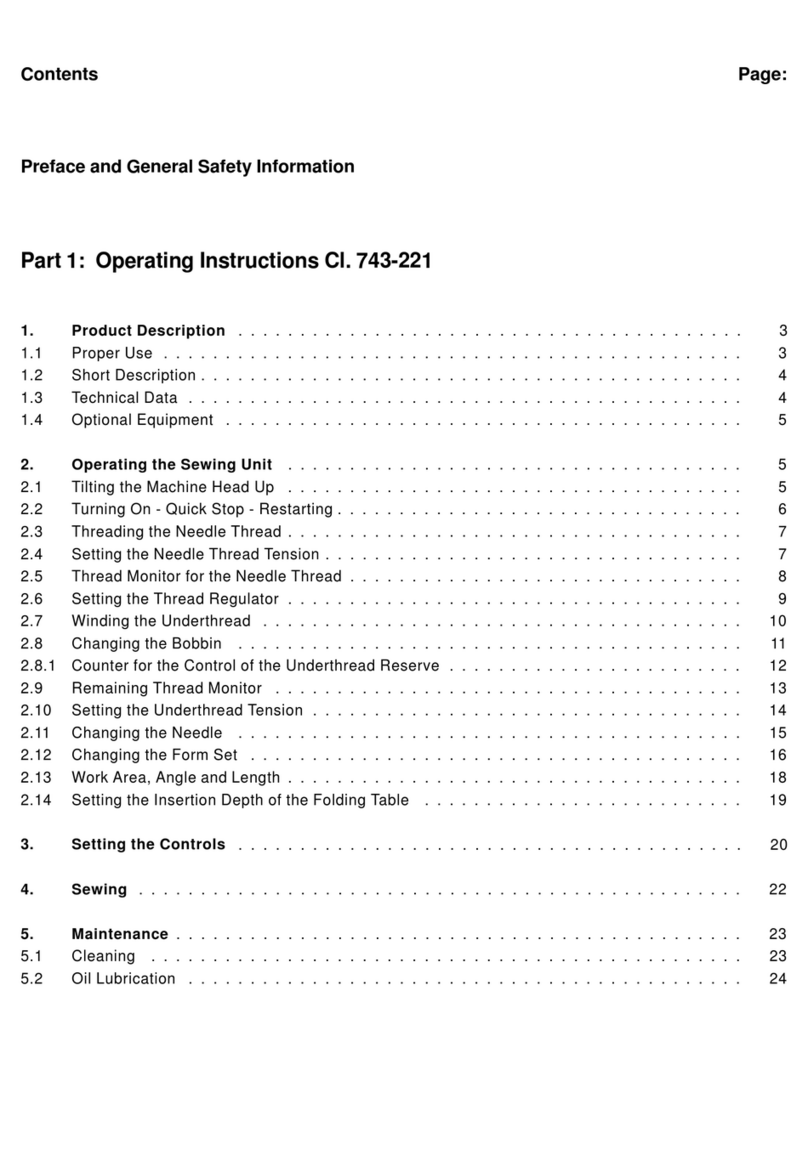

Contents page:

7. Operating and adjusting the DC1500/DA220C direct-current

positioning actuator ............................ 24

7.1 DA220C control operating and display elements ............ 25

7.1.1 Changing parameter values at operator level with the DA220C control. . . 26

7.1.1.1 Calling and changing operator-level parameters one after the other

with the DA220C control ........................... 26

7.1.1.2 Calling and changing operator-level parameters directly with the

DA220C control ................................ 27

7.1.2 Reducing the maximum speed with the DA220C control ........ 27

7.1.3 DA220C control operator-level parameter list .............. 28

7.1.4 Changing technician-level and manufacturer-level parameter values . . 29

7.1.5 Setting positions with the DA220C control ................ 30

7.1.6 Setting machine-specific parameters with the DA220C control .... 32

7.1.6.1 General ..................................... 32

7.1.6.2 Autoselect................................... 32

7.1.6.3 Table of DA220C control machine-specific parameters......... 32

7.1.7 Master reset with the DA220C control ................... 33

7.1.8 Condition and error messages ....................... 34

7.2 V810 operating panel (optional equipment)................ 35

7.2.1 Operating and display elements on the V810 operating panel..... 35

7.2.2 Key functions on the V810 operating panel................ 35

7.2.3 Meaning of the symbols on the V810 operating panel ......... 36

7.2.4 Changing parameter values at operator level .............. 37

7.2.5 Reducing the maximum speed ....................... 37

7.2.6 Changing technician-level and manufacturer-level parameter values

with the V810 operating panel ....................... 38

7.2.7 Setting positions with the V810 operating panel ............. 39

7.2.8 Setting machine-specific parameters with the V810 operating panel . . . 40

7.2.9 Master reset with the V810 operating panel ............... 40

7.2.10 Condition and error messages on the V810 operating panel...... 40

7.3 V820 operating panel............................. 41

7.3.1 Operating and display elements on the V820 operating panel..... 41

7.3.2 Key functions on the V820 operating panel................ 41

7.3.3 Meaning of the symbols on the V820 operating panel ......... 43

7.3.4 Changing parameter values at operator level .............. 44

7.3.5 Reducing the maximum speed ....................... 44

7.3.6 Quickinformationandquicksettingsentry(HIT) ............ 44

7.3.7 Changing technician-level and manufacturer-level parameter values

with the V820 operating panel ....................... 45

7.3.8 Setting positions with the V820 operating panel ............. 46

7.3.9 Setting machine-specific parameters with the V820 operating panel . . . 47

7.3.10 Master reset with the V820 operating panel ............... 47

7.3.11 Condition and error messages on the V820 operating panel...... 48

7.3.12 Seam programming with the V820 operating panel ........... 48