PHOTON SYSTEM

Installation Guide

(rel. 8.0)

Fig. 1

General description of the system

The Photon system by Deitech, in its basic configuration, is

made of two bars absolutely identical (Fig. 1), placed at the two

ends of the area to be controlled thus creating an “infrared

barrier”; the bars are connected with just one cable to a hub

(Fig. 2), that, placed in the Control Unit, controls the whole

system. The bars are used for both transmission and reception

of the beams, work in couple and exists in different versions:

from 50 to 200 cm height, with or without heather, with maximum

range 25, 50 and 80 meters. They have all the same design; are

made of an aluminium body with a black polycarbonate cover

and two caps of the same colour.

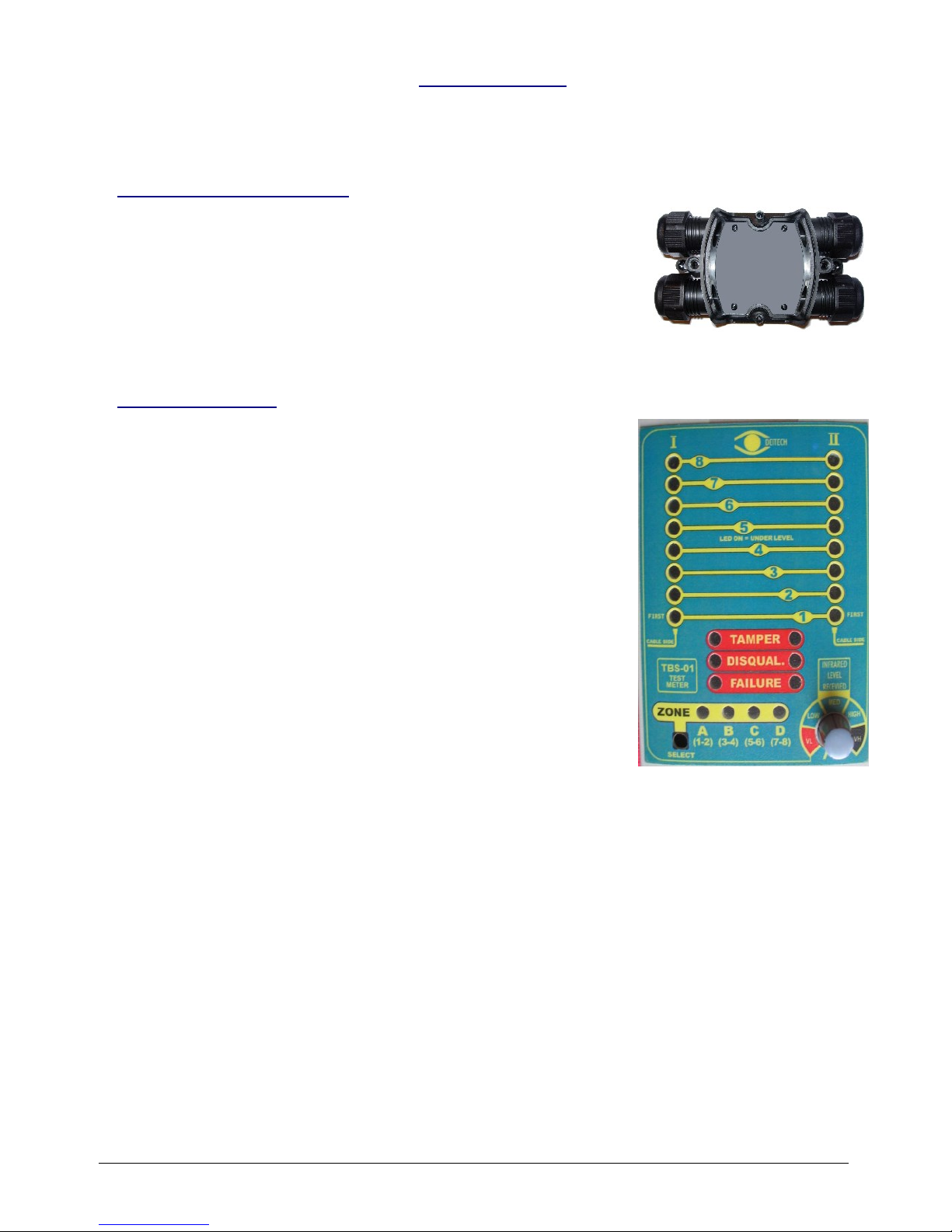

On the “ROTAX” cap (Fig. 3) you can

find the connection terminals and the

ROTAX system for the orientation of

the beams. On the “NUMBER” cap

(Fig. 4) there is the selector for the ID

number to assign to the bar and, in the

models with heater, the terminal blocks

for heater power supply. Through a four

wires cable plus shield, the barriers

(from ROTAX cap) will be connected to

the hub; the connection could be a star

or in series so that it can easily adjust

to the different installation

requirements.

The hub controls the correct operation of the barriers, allows the configuration of the system

and concentrate the connexion with the control panel. The hub will manage up to a maximum

of four couples, that can be installed even in the same area and the beams will not interfere

between themselves. The four couples can be of different heights and different range but the

bars of each couple must be the same. For each couple the hub will allow to set different

operation parameters (see HUB-TC Manual for details) and manage single stand-by inputs.

The alarm output toward the control panel are different for each couple, while the technical

outputs (tamper, disqualification, failure) are common for all the couples managed by the hub.

If the installation will require more than four couples, then more hub are needed.

THE BARS

It’s absolutely fundamental to install the couple of bars properly, each couple must be placed in order

to protect the passage through which an intruder could pass. In order to determine the correct mounting

height of the bar, it must be taken into consideration that the first beam (and the last) is placed at about

20 cm from the end of the bar and that between the other beams there are 25 cm. The barrier can be

placed upside down to connect the hub either from above or from below, but it is mandatory that each

couple is installed in the same position. All the Photon barriers have a patented system that allows a

correct horizontal alignment of the beams (ROTAX). This system will enable the installer to install them