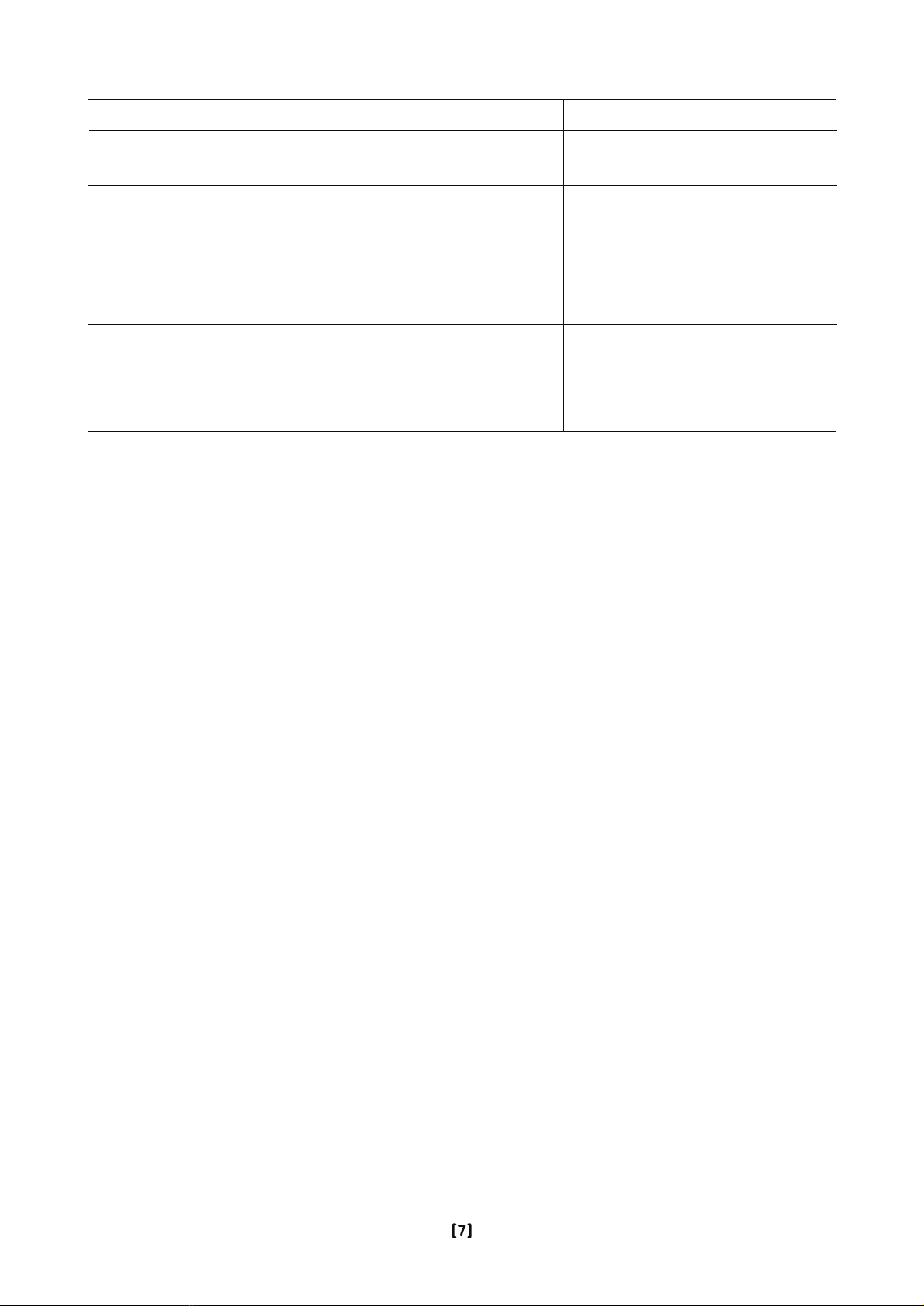

10. Breakdown & Solve-Method

11. Quality Warranty

Fault state Cause Countermeasure

Not work

No refrigeration

Water leaks out

The power plug has been loosed Insert the plug into wall socket well

Fuse was broken Ask the purchase agent for help

Drain pipe is blocked

Water tank is not installed correctly

Filter is dirty

Water tank full of water

Clean the drain pipe

Install it in the right place

Clean the filter

Pour the water out

Condenser’s surface is dirty and blocked

Heat exhaust fan was breakdown

External environment’s temperature is too high

The capacity of compressor was damaged

Refrigeration system’s pipeline is blocked

Input voltage is too high or too low

Compressor’s motor is fault

Clean the condensor’s surface and

vantilate or cool for the condensor

Change the heat exhaust fan

Select the suitable place to use

Change the capacitor

Change the pipeline system

Select the suitable voltage to use

Repair and change the compressor

Ș

The warranty period of our air conditioner is one year.To provide the better service for our customers,

Our

company specially set up the technical service department.We will do our best to provide the good

service to our customers.

ȘThis products have been inspected according to the national related standard before sale.

If the customers comply with all regulation referring in the instruction and the products’warranty period

does not exceed more than one year(based on the invoice’s date).If the machine is fault because of its

quality.With the invoice and warranty, our technical service department can provide the free

maintenance service for you.

ȘAccording to the regulation of instruction to installation and operate the air conditioner. If the machine

is damaged because of deregulation and the other customer reasons, it is not belong to warranty range.

ȘThe customers disassembly or converse the products themselves or the machine breaks down but not

to notice our technical service department,then it means giving up the warranty rights.

ȘIf the fee is out of the warranty period or not belong to the warranty range, the service and travel

expenses must be undertaken by customers.

ȘOur company can train the operation and maintanence staff for our customers.