SENTRONIC SUPERPROX SM504 Series User manual

SUPERPROX® PROXIMITY

SENSORS

Model SM504 Series

SU PE R PROX ®

Ultrasonic

Proximity

Sensors

Synchronized/

Gate-controlled

Sensing

Sensing full or empty case

conditions is greatly simplified

with these SUPERPROX®sen-

sor models. Other typical appli-

cations include sensing height

differentiation, detecting object

surfaces in specific areas, and

performing on-demand and

automation-control sensing

functions.

The SUPERPROX®Model

SM504B (cable style) and Model

SM554B (connector style) se-

ries of ultrasonic, proximity sen-

sors, when used in a set, pro-

vide for external control of the

pulsing of all the sensors. A

setup switch in these sensors,

designated “Master” and “Slave,”

selects the operating technique

• Allows sensors

to operate in close

proximity

• Detects objects at

specific points within

adjustable “window”

limits

• Makes profiling and

positioning

applications possible

• A push-button sets

window limits

• Operating range up to

2 m (79")

• CE certified

to either simultaneously synchro-

nize or gate the transmit and re-

ceive cycles of a multiple sensor

set.This unique concept is an ef-

fective solution for applications

such as: full or empty case in-

specting, on-demand controlled

sensing or inspecting, in-case

container counting, automation

control sensing, object-in-area

sensing, down container sensing,

differential height inspecting, and

more.

The synchronized technique is

designed for applications requir-

ing continuous “curtain” sensing

over a wide area. Synchronized

sensing allows any number of sen-

sors to be operating close to-

gether, thus eliminating any pos-

sible adverse ultrasonic signal in-

terference between the sensors.

Controlled or multiplexed sens-

ing of multiple objects, locations

or surfaces is accomplished us-

ing the gated technique.With this

technique, PLS and PLC output

switches or other sensing devices

may be used to trigger or gate a

sensor set. Depending on the ap-

plications, a set of these sensors

is used with an isolated switching

device to prevent possible false

sensor outputs due to changing

foreground object conditions.

Like other SUPERPROX®sen-

sors, these models have the ca-

pability to detect objects at spe-

cific points within adjustable “win-

dow” limits, thus making profiling

and positioning applications pos-

sible. A push-button sets the win-

dow limits. The sensors carry the

CE Mark and are epoxy sealed in

a tough plastic housing to resist

harsh, wet, or dirty environments

typically associated with the above

applications. The housing meets

NEMA 4X (indoor use only) and

IP67 industry standards. A Dairy

3A compliant housing is available

as an option. These sensors have

operating ranges of 51 to 635 mm

(2 to 25"), 51 to 1 m (2 to 39") and

120 mm to 2 m (4.7 to 79") and are

available in 12 to 24 VDC model

versions. 4-47

Rugghölzli 2

CH - 5453 Busslingen

Tel. +41 (0)56 222 38 18

Fax +41 (0)56 222 10 12

www.sentronic.com

Produkte, Support und Service

SEN

TRONIC

AG

Sensor Configuration

Switches

Switch 1 configures the sensor to op-

erate in either a normal or high sensitiv-

ity mode. Place this switch in the NORM

position for sensing liquid or solid mate-

rials. Place the switch in the HIGH posi-

tion for sensing soft or porous materials

that will absorb some of the ultrasonic

energy.

Switch 2 configures the sensor to op-

erate in either an object or background

sensing mode. Place this switch in the

OBJCT position to perform a sensing

function for receiving the reflected ultra-

sonic energy directly off an object. Place

this switch in the BKGRD position to

perform a break-beam sensing function

for receiving the reflected ultrasonic en-

ergy directly off a fixed background tar-

get.

Switch 3 selects the operating mode

for the sensor output to be either nor-

mally open (N.O.) or normally closed

(N.C.).

Switch 4 configures the sensor to per-

form either a slave or master operating

function. See Synchronized Sensing and

Gate-controlled Sensing descriptions for

selecting the proper switch position.

Control Compartment

A unique feature available to the user

of these sensors is the ability to quickly

set up each sensor for a specific appli-

cation.The sensor is configured through

four slide switches and a push-button

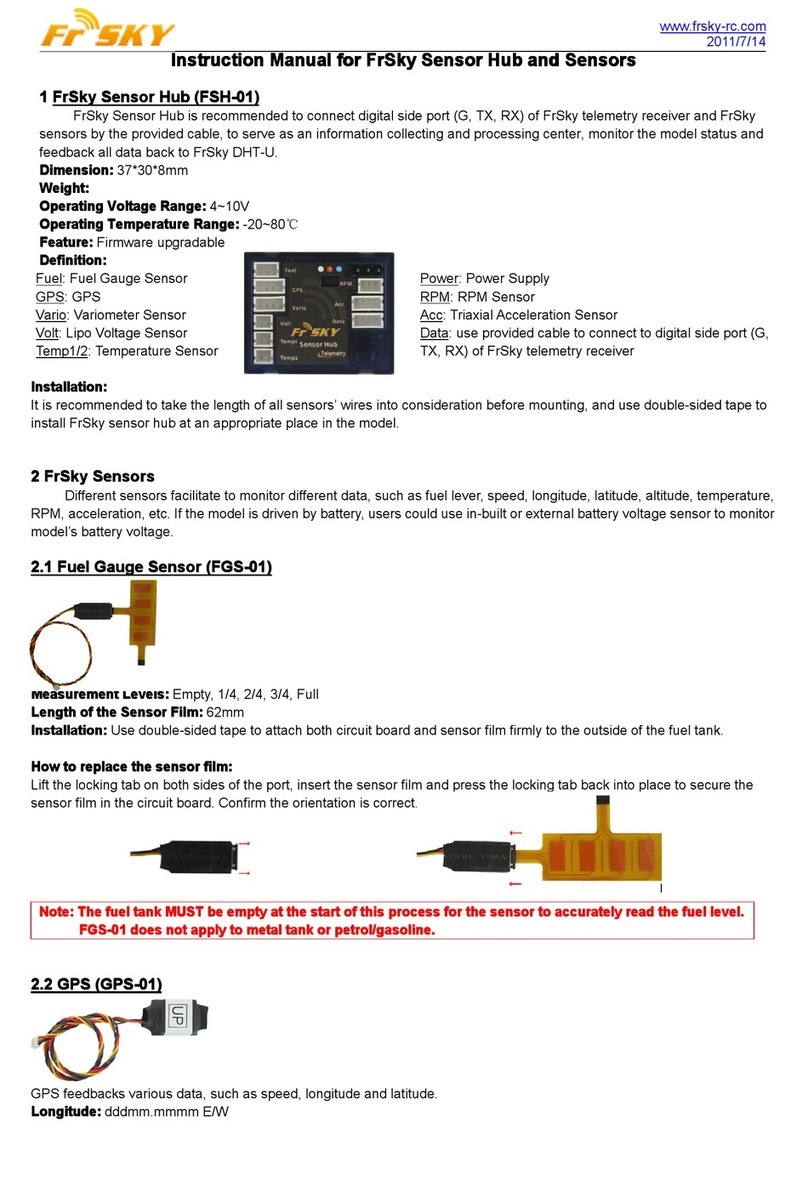

Synchronized Sensing

Synchronized sensing is a unique fea-

ture of this sensor that enables reliable

“curtain” sensing or inspecting over a

wide area by using multiple sensors in

a set. Synchronized sensing allows

these sensors to be operated close to-

gether, thus eliminating any possible

adverse ultrasonic signal interference

between the sensors.

Any number of these sensors can be

operated together to perform a synchro-

nized sensing function. It is accom-

plished by simply connecting together

the external control wire lead from all

the sensors in the set as shown in the

illustration on the next page. One of the

connected sensors must operate with

setup Switch 4 in the “Master” position

and the other connected sensors must

operate with setup Switch 4 in the

“Slave” position.The designated “Mas-

ter” sensor continuously synchronizes

the transmit and receive cycles of all

the connected sensors as a result of

this configuration.

Figure 1

1234

NORM

OBJCT

N.O.

SLAVE

HIGH

BKGRD

N.C.

MASTER

LIMITS

Model Reference Guide - SM504 Series

Use the guide below to ensure the correct model number is specified for the

application. Please note that not all sensor model combinations are available.

EXAMPLE MODEL: SM5 5 4 B - 4 00 - AF

SUPERPROX®Product Series

Power/ConnectionType (DC only)

0...12 to 24 VDC / cable style

5...12 to 24 VDC / connector style

Sensing Function

4...Proximity - Synchronized/Gate-controlled

Design Level

A…Applies to discontinued models with NPN sinking output only

B…Applies to models with NPN sinking and PNP sourcing outputs

Sensing Range

0...51 to 635 mm (2 to 25")

1...51 to 1 m (2 to 39")

4...120 mm to 2 m (4.7 to 79")

Functionality

00...Standard Proximity

05...Default Window: ±0.5"

44...Default Window: ±0.1"

67...Switch selectable, 1 or 2 echo hit recognition with high gain

Special Features

...No letter indicates standard sensor with no special features

FS...Fluorosilicone transducer face

AA...Remote limit setup (Available on DC cable models only.)

AB...RS232, 4-digit/2-decimal place output (Available on cable models only.)

AD...Limits push-button disabled

AE...RS232, 5-digit/3-decimal place output (Available on cable models only.)

AF...No LEDs

HousingTypes

...No letter indicates standard ULTEM®* plastic housing

N...NORYL®* Dairy 3A gray plastic housing

RemoteType

...No letter indicates standard couopler

R...Right-angle sensing head with armor cable

S...Straight sensing head with armor cable

Remote Cable Length

...No number indicates standard coupler

1...254 mm (10")

2...508 mm (20") 5P...1270 mm (50")

3...762 mm (30") 6P...1524 mm (60")

4...1016 mm (40")

* ULTEM®and NORYL®are registered trademarks of The General Electric Company.

4-48

Available in PVC cable only

Armored (standard) or

PVC cable (specify P

after number)

(See Figure 1) located inside a wa-

ter-tight control compartment on the

sensor.To access the controls, remove

the small square cover on the back of

the sensor. Simply loosen the two flat-

head cover screws and insert a small-

blade screwdriver in either the top or

bottom slot to remove the cover. A short

plastic tether prevents separation of the

cover from the sensor. NOTE: The

switch settings may require changing

for the intended application.

Rugghölzli 2

CH - 5453 Busslingen

Tel. +41 (0)56 222 38 18

Fax +41 (0)56 222 10 12

www.sentronic.com

Produkte, Support und Service

SEN

TRONIC

AG

Sensor Limits Setup

Push-button

First, during installation make sure the

sensor face is as parallel as possible

to the surface of the material being de-

tected.

To set the limits, simply place an ob-

ject at the desired distance from the

sensor for one limit and press the

LIMITS push-button once.This sets the

first limit and switches the sensor out-

put to an inactive state during the limit

setup.While the LIMITS push-button is

depressed, the multicolored LED lo-

cated on top of the sensor, is amber.

Upon release of the push-button, the

LED flashes amber indicating that the

second limit needs to be set within 30

seconds. Place an object at the desired

position for the second limit and press

the LIMITS push-button once. Again

while the push-button is depressed, the

LED is amber. Upon release of the

push-button, the LED flashes amber

momentarily and then turns green to

indicate acceptance of both limits. If 30

seconds elapse before the second limit

is set, the limits revert back to the pre-

vious settings.

At the same time, the sensor output

switches from the inactive to the ac-

tive state, placing the sensor into the

operational mode, ready to use. When

power is off or interrupted, the limits

are retained in a nonvolatile memory.

If in setting either limit the echo from

the object is too weak or distorted, the

LED flashes RED for 10 seconds (or

until the button is pressed again) indi-

cating the limit setting was not accepted

by the sensor. Attempt to set both lim-

its again, being careful to keep the ob-

ject surface parallel to the face of the

sensor.

Minimum allowed distance between

any two setup limits is 13 mm (1/2").

The multicolored LED flashes RED af-

ter the press and release of the LIM-

ITS push-button for the second limit

setting if the distance between the limit

settings is less than 13 mm.The multi-

colored LED continues flashing RED ei-

ther until the LIMITS push-button is

pressed and released once for the first

limit setting or until 10 seconds have

elapsed. Pressing and releasing the

LIMITS push-button once reinitiates the

limit setup sequence. If 10 seconds

elapse before the LIMITS push-button

is pressed and released for the second

limit setup, the limits revert back to the

previous settings.

A special feature provides an auto-

matic 13 mm (1/2") window limits setup

function. Simply place an object within

the sensing range of the sensor and

press the LIMITS push-button twice in

succession without moving the object.

A limit is set on a line 1/4" in front and

back of the object surface nearest the

sensor.

Multicolored LED Indicator

During Limit Setup

Prior to pressing LIMITS push-

button:

• Off - Sensing no object or

object is outside of the

sensing range

• Red - Sensing an object out

side the set limits

• Green - Sensing an object

inside the set limits

LIMITS push-button depressed for

first time:

• Amber - sensing a good object

surface condition

• Red - Sensing no object or a

poor object surface condition

LIMITS push-button released for

first time:

• Flashing Amber - First limit

accepted,waiting for second

limit

• Flashing Red - First limit not

accepted; retry setting limit

LIMITS push-button depressed for

second time:

• Amber - Sensing a good

object surface condition

• Red - Sensing no object or a

poor object surface condition

LIMITS push-button released for

second time:

• Green or Red - Second limit

accepted

• Green or Amber - Second

limit accepted

• Flashing Red - Second limit

not accepted; retry setting

both limits

Multicolored LED Indicator

in Operational Mode

• Off - Sensing no object or

object is outside the sensing

range

• Red -

Sensing as object

outside the set limits

• Green -

Sensing an object

inside the set limits

Red LED Indicator in

Operational Mode

The red LED serves as a visual

indicator for the sensor output. The

LED is illuminated when the output

is in an active (ON) state. Note:

Indicator is not provided on all

models.

Electrical Wiring

Sensor wires must be run in

conduit free of any AC power or

control wires.

4-49

View of Plug on Connector Style

Sensor

BLACK1

NPN

ORANGE

3

Sync/Gate

WHITE 5

PNP

BLUE 2

Common

BROWN 4

+ 12 to 24 VDC

Gate-controlled Sensing

Gate-controlled sensing is another

unique feature that enables this sensor

to perform periodic sensing of multiple

objects or locations. Depending on the

application, one or a set of these sen-

sors is used with an isolated switching

device for preventing possible false

sensor outputs due to changing fore-

ground object conditions. Devices such

as SUPERPROX®sensors, program-

mable limit switches or other proximity

sensor switches with an open-collec-

tor, current sinking output are typically

used to perform the isolated gate-switch

or “Master” sensor function.

Gate-controlled sensing is accom-

plished by connecting the external con-

trol wire lead from each sensor to the

DC supply voltage common through the

isolated switch as shown in the illus-

tration on the next page. Each con-

nected sensor must operate with setup

Switch 4 in the “Slave” position. In this

configuration, the sensors simulta-

neously transmit and receive ultrasonic

energy only when the gate device is

switched to the ON or CLOSED state.

When the gate device is switched back

to the OFF or OPEN state, the sensor

outputs are latched from changing state

until the next gate-switch cycle.

SUPERPROX® PROXIMITY

SENSORS

Sensor Wire colors

Cable Connector

Style Style

(+)12 to 24 VDC RED BROWN

NPN/Sinking Output WHITE BLACK

PNP/Sourcing Output BROWN WHITE

Sync/Gate Control GREEN ORANGE

DC Common BLACK BLUE

Rugghölzli 2

CH - 5453 Busslingen

Tel. +41 (0)56 222 38 18

Fax +41 (0)56 222 10 12

www.sentronic.com

Produkte, Support und Service

SEN

TRONIC

AG

Synchronized Sensing

Connections

#4 stainless steel screw

(SEM retained) 2x

Pry notch

(2-PL)

Access door to control

compartment w/ gasket

& retaining cable

1/2" NPT pipe thds.

for conduit mtg.

Sealed cable

3 meters long

(10 ft)

Sensing face

78 mm

(3.06)

44 mm

(1.75)

22 mm

(.87)

92 mm (3.63)

79 mm (3.13)

51 mm

(2.00)

35 mm DIA

(1.37)

#4 stainless steel screw

(SEM retained) 2x

Pry notch

(2-PL)

Access door to control

compartment w/ gasket

& retaining cable

7/8"-16 UNF

threads

Sensing face

106 mm

(4.17)

44 mm

(1.75)

22 mm

(.87)

92 mm (3.63)

79 mm (3.13)

51 mm

(2.00)

35 mm DIA

(1.37)

Stainless steel

sensing probe

25 mm (1.0") long x

13 mm (1/2") diameter

Straight

style

Right angle

style

Stainless steel armor cable

254 mm (10"), 500 mm (20"),

762 mm (30"), 1016 mm (40")

long x 5 mm (3/16") diameter

Note: Illustrated models may not be the exact

representation for these sensors due to possible

design modifications.

REMOTE HEAD

REF.

51.0 mm

(2.000)

28.5 mm

(1.120)

16.0 mm

(.630)

AC230

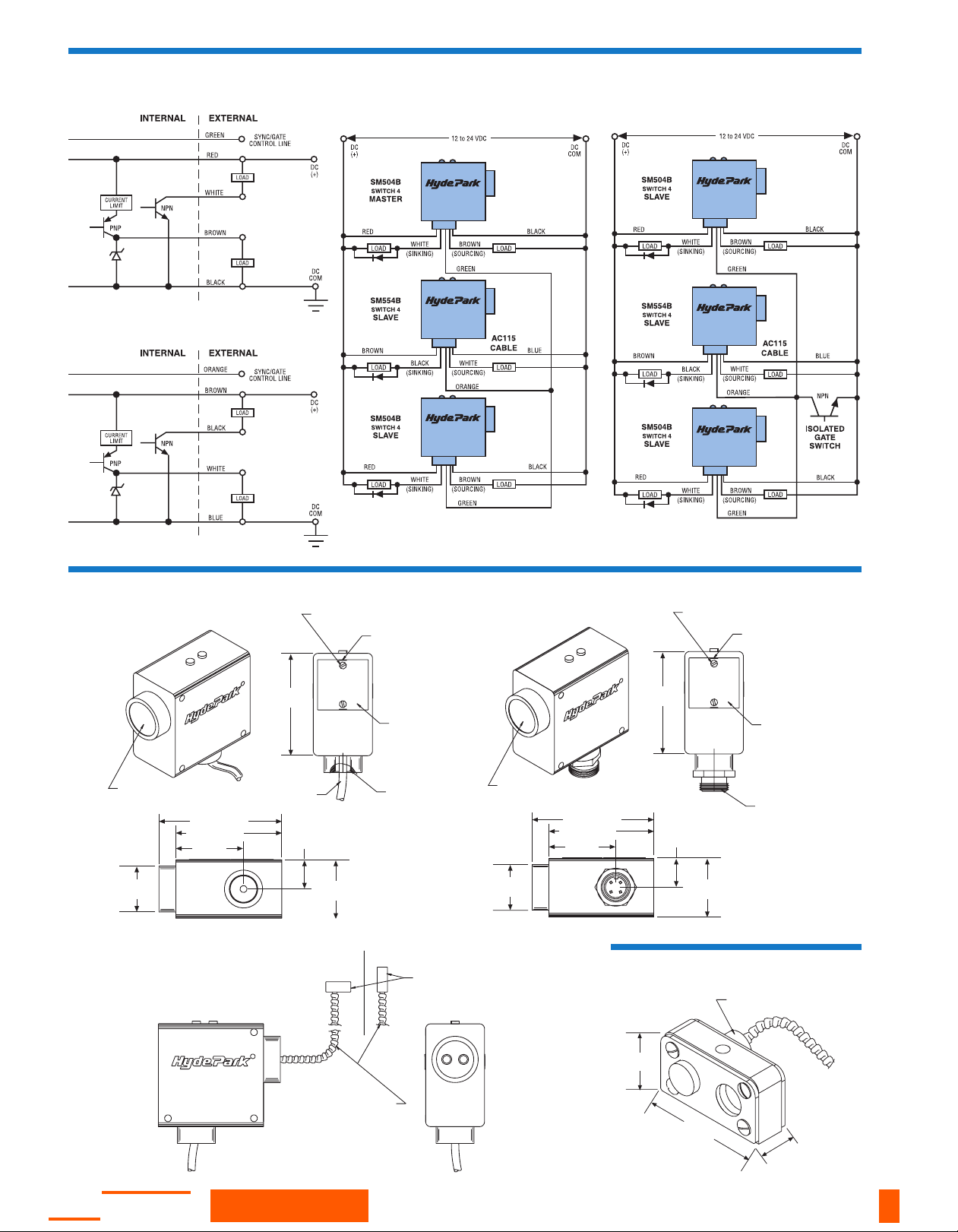

Mounting Accessories

Dimensions

Cable Model Connector Model

Remote Sensing Models

Cable Model

Connector Model

Outputs

4-50

Gate-controlled Sensing

Connections

Rugghölzli 2

CH - 5453 Busslingen

Tel. +41 (0)56 222 38 18

Fax +41 (0)56 222 10 12

www.sentronic.com

Produkte, Support und Service

SEN

TRONIC

AG

Accessories

Model AC115, Straight, 7/8-16 mini, 5-conductor,

mating connector cable, 4 m (12'), for Model

SM554B-XXX series connector-style prox sensors

with alarms

Model AC115-50, Straight, 7/8-16 mini, 5-conductor,

mating connector cable, 15 m (50'), for Model

SM554B-XXX series connector-style prox sensors

with alarms

Model AC213, Stainless and Teflon, remote sensing

probe mounting bracket

Model AC222, Standard, stainless mounting bracket

assembly, slotted for vertical adjustment

Model AC226, Stainless and polyamide conveyor-rail

clamp/bracket set

Model AC229, Stainless, plate-style, right-angle,

mounting bracket, with base slotted for forward

reverse adjustment and side slotted for sensor

adjustment

Model AC230, Three-piece, stainless, mounting

bracket assembly with O-ring mount for sensor

models with remote heads.

See page 7-1 for accessory photos.

General Specifications

Sensing

Ranges:

51 to 1 m (2 to 39")

120 mm to 2 m (4.7 to 79")

Sonic Frequency: 200 kHz

Power Requirements

DC Models:

12 to 24 VDC ± 10% @ 80 mA, 2 W max.,

excluding output load (regulated supply)

Output/Input

DC Models:

NPN Sinking: Switch selectable N.O./N.C.

Sinking on-state voltage drop:

Maximum 0.25 volts @ 60 mA

Sinking load current:

Maximum 100 mA

Sinking output voltage:

Maximum applied 30 VDC

PNP Sourcing: Switch selectable N.O./N.C.

Sourcing output current:

Maximum 100 mA

Current limit protected to less than 160 mA

Input:

Input voltage range: 0 to 30 VDC

Vin-high, minimum: 2.5 V

Vin-low, maximum: 1.4 V

Input current maximum: 0.76 mA

ResponseTime

“On” 10 ms, “Off” 10 ms to “On” 30 ms,

“Off” 30 ms, depending upon model

Indicators

Multicolored (Amber, Red, Green) LED: Indicates

limits setup and operational modes

Red LED: Visual indicator for sensor output;

illuminated when output is in an active (On) state.

Connections

Cable Style Models:

DC: 24 AWG, PVC jacket,

5-conductor, 3 meters (10') long, standard

Connector Style Models:

DC: 5-pin “mini” style

Protection

Power Supply: current-limited over-voltage, ESD,

reverse polarity

Outputs, Input: current-limited over voltage, ESD,

over-current.

Environmental

Operating Temperature Range:

0oto 50oC (32oto 122oF)

Storage Temperature Range: -40oto 100oC

(-40oto 212oF)

Operating Humidity: 100%

Protection Ratings: NEMA 4X (indoor use only),

IP67

Chemical Resistance: Resists most acids and

bases, including most food products.

Fluorosilicone transducer face is available to

provide resistance to aromatic and petroleum-

based hydrocarbons.

Agency Approvals

CE Mark: CE conformity is declared to:

EN61010-1: 1990 including amend. No.1:1992

EN55011 Group 1 Class A, EN50082-1.

Declaration of conformity available upon request.

AC Models SM520/570 carry the ETL safety label.

Construction

Dimensions (overall)

92 mm (3.625") L x 44 mm (1.75") W

x 91 mm (3.58") H

Housing:

Case: ULTEM®* (FDA approved)

Optional: NORYL®* (USDA-Dairy 3A

Sanitary Standards compliant)

Transducer Face: Silicone rubber (FDA ap-

proved)

Optional: Fluorosilicone rubber

Sensor Cable: PVC jacket

LED: Polycarbonate

* ULTEM®and NORYL®are registered trademarks of The General

Electric Co.

Sensing face

(outline of

SUPERPROX ref.)

Multi-colored LED

sensing indicator

Red LED output

indicator

Upper mtg. bracket

stainless steel

Note: Bracket is abl

e

to be rotated

#10-32 x 57 mm (2 1/4”) lg

stainless steel screw

& ESNA nut (farside)

2-places

#10-32 x 12.7 mm (1/2”) lg

stainless steel screw

& ESNA nut

2-places

Lower support bracket

stainless steel

with two 35 mm lg x 7.1 mm wd slots

(

1.380 x .280

)

49 mm

(1.93)

25.4 mm

(1.00)

52 mm

(2.06)

147 mm

(5.78)

95 mm

(3.75)

51 mm

(2.00)

92 mm

(3.63)

79 mm

(3.13)

14.3 mm

(.56)

13 mm

(.52)

44 mm

(1.75)

78 mm

(3.06)

143 mm

(5.63)

71 mm

(2.78)

64 mm REF

(2.52)

65mm

(2.56)

91.44 mm

(3.60)

65.00 mm

(2.56) 2x

6.6 mm 2x

(.23) Wide

11.43 mm

(4.50)

72.00 mm

(2.83) 2x

30.5 mm (2x)

(1.20)

13.2 mm

(.52) 2x

R 6.35 mm

(.25)

FULL R.

TYP

31.0 mm

(1.22)

20

û

56 mm

(2.20)

R 4.8 mm

(.19)

45

û

3.17 mm

(.125) TYP

FULL R.

TYP

65.00 mm

(2.56) 2x

13.2 mm

(.52)

101.60 mm

(4.00)

45.7 mm

(1.80)

91.44 mm

(3.60)

38.0 mm

(1.50)

19.00 mm

(.75)

R 8.0 mm

(.31) 4x

7.10 mm

(.28) 2x

.204 DIA THRU

0.52 cm

R .750

1.91 cm

.750

1.91 cm

.376

0.96 cm

1.186

3.01 cm

.064

0.16 cm

.438

1.11 cm

.128

0.33 cm

AC222

Mounting Accessories

AC213

4-51

SUPERPROX® PROXIMITY

SENSORS

Rugghölzli 2

CH - 5453 Busslingen

Tel. +41 (0)56 222 38 18

Fax +41 (0)56 222 10 12

www.sentronic.com

Produkte, Support und Service

SEN

TRONIC

AG

4-52

SM504 Series

Proximity Synchronized & Gate-controlled Sens-

ing

12-24 VDC

Cable

Connector

2m(79")

1 m (39")

635mm (25")

Standard

Rt. Angle

Straight

Silicone*

Fluorosilicone*

ULTEM

®

*

NORYL

®

*

Default Window

Notes

Power Version

Connection

Style

Sensing

Range

Transducer

Style

Materials

Special

Features

Remote

Transducer Housing

Model No.

SM504B-000•�� �� ��

SM504B-000 AA �� �� �� Remote limit setup

SM504B-005 AA �� �� ��

±0.5"

Remote limit setup

SM504B-067 �� �� �� Switch selectable, 1 or 2 echo, hit recognition with high gain

SM504B-100•�� � � ��

SM504B-100 R3 � � � �

(30")

��

SM554A-067 � � �� �Switch selectable, 1 or 2 echo, hit recognition with high gain

SM554B-000•� � �� ��

SM554B-000 S4 �� � �

(40")

��

SM554B-005 � � �� ��

±0.5"

SM554B-044 � � �� ��

±0.1"

SM554B-067 � � �� �� Switch selectable, 1 or 2 echo, hit recognition with high gain

SM554B-100•���� ��

SM554B-105 ���� ��

±0.5"

SM554B-400 AF � �� � �� No LEDs

Selection Chart

• = Most commonly stocked sensors

* = See definition in

Sensing Terms

.

All possible sensor configurations are not listed here.

Rugghölzli 2

CH - 5453 Busslingen

Tel. +41 (0)56 222 38 18

Fax +41 (0)56 222 10 12

www.sentronic.com

Produkte, Support und Service

SEN

TRONIC

AG

Table of contents

Other SENTRONIC Accessories manuals

Popular Accessories manuals by other brands

Stahl

Stahl 8579/61 Series operating instructions

Schmalz

Schmalz FS-5-D-2NA-K Assembly instructions

Monoprice

Monoprice 7933 instruction manual

Centrica

Centrica PAN-42 Operation and maintenance manual

Cooper Lighting

Cooper Lighting HALO Home HIWMSB1BLE40AWH installation instructions

CS Instruments

CS Instruments VA 521 instruction manual