Telaire Ventostat™ 8000 Series Page 3

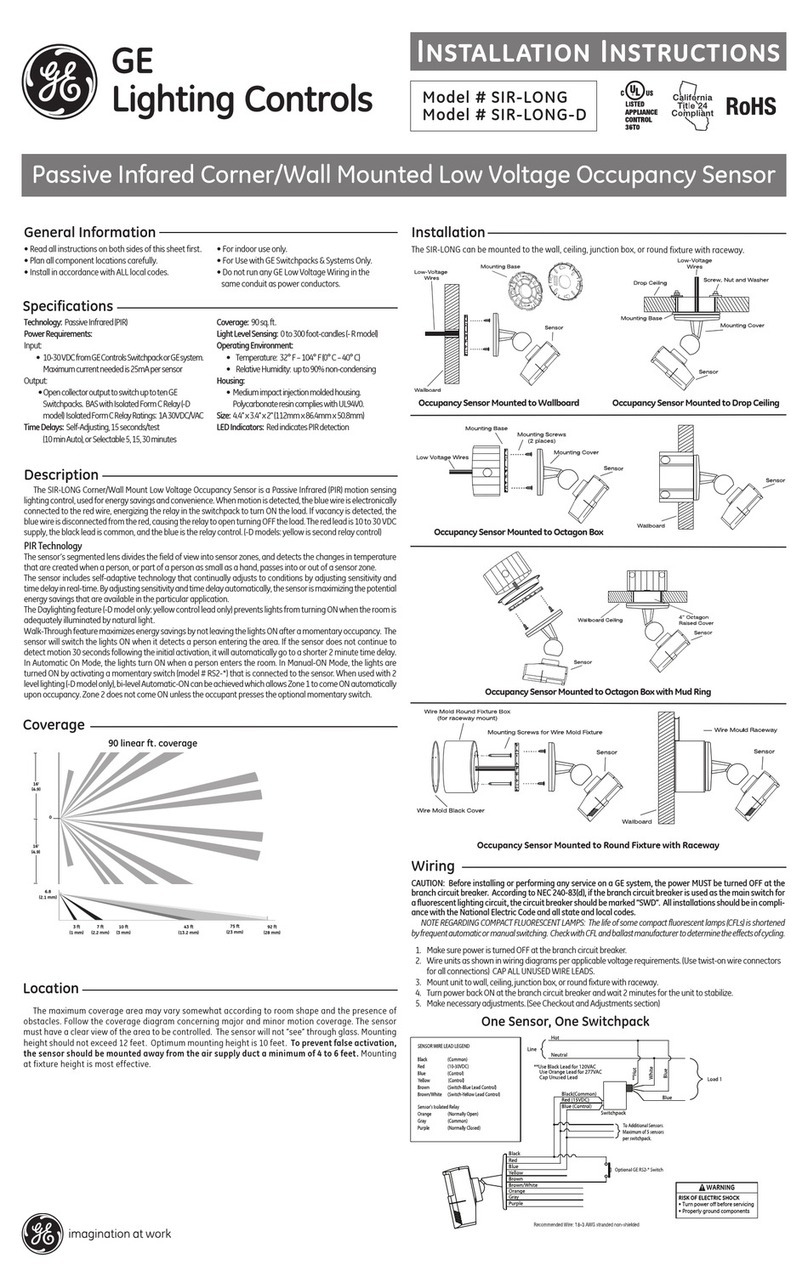

Set minimum position potentiometer to twice the design load. For

example, if the space is designed for 30 people at 15 cfm/person, adjust

the minimum position potentiometer at the economizer logic to 900 cfm.

This will allow the economizer to introduce 450 cfm (1000 ppm CO2

level) at the design load. The CO2sensor should use “STDSET#1.”

Note: For 24V, do not use a HVAC unit transformer. Provide

24 V by using a non-grounding transformer.

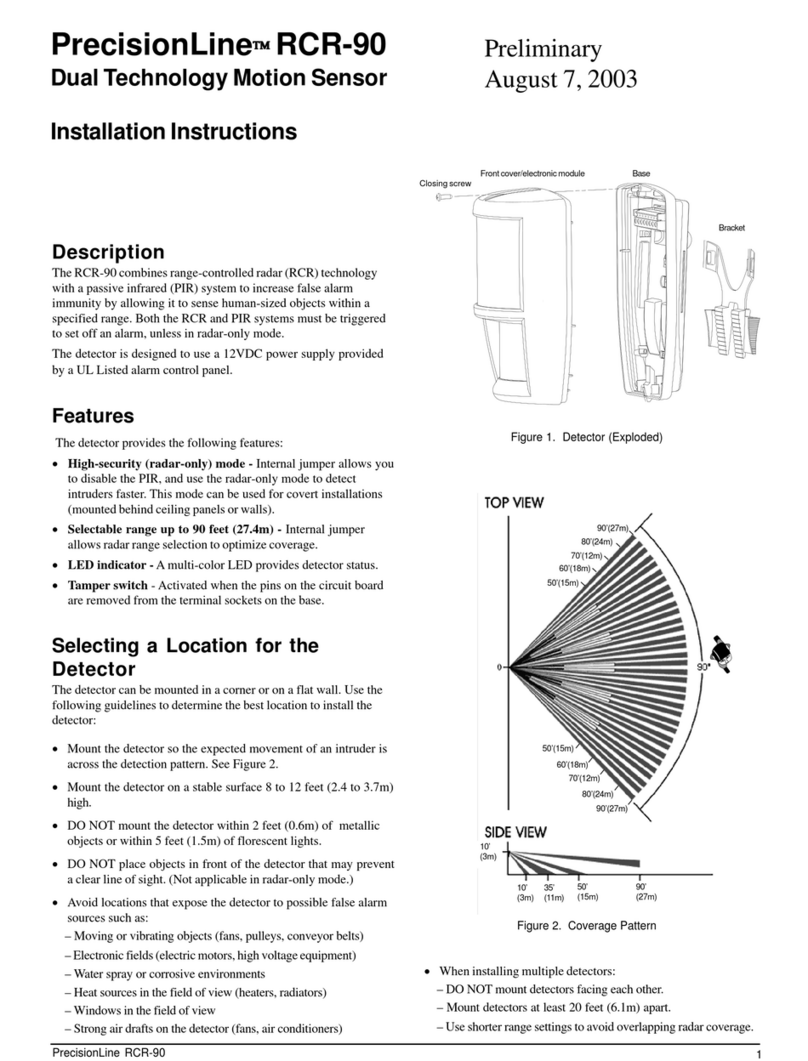

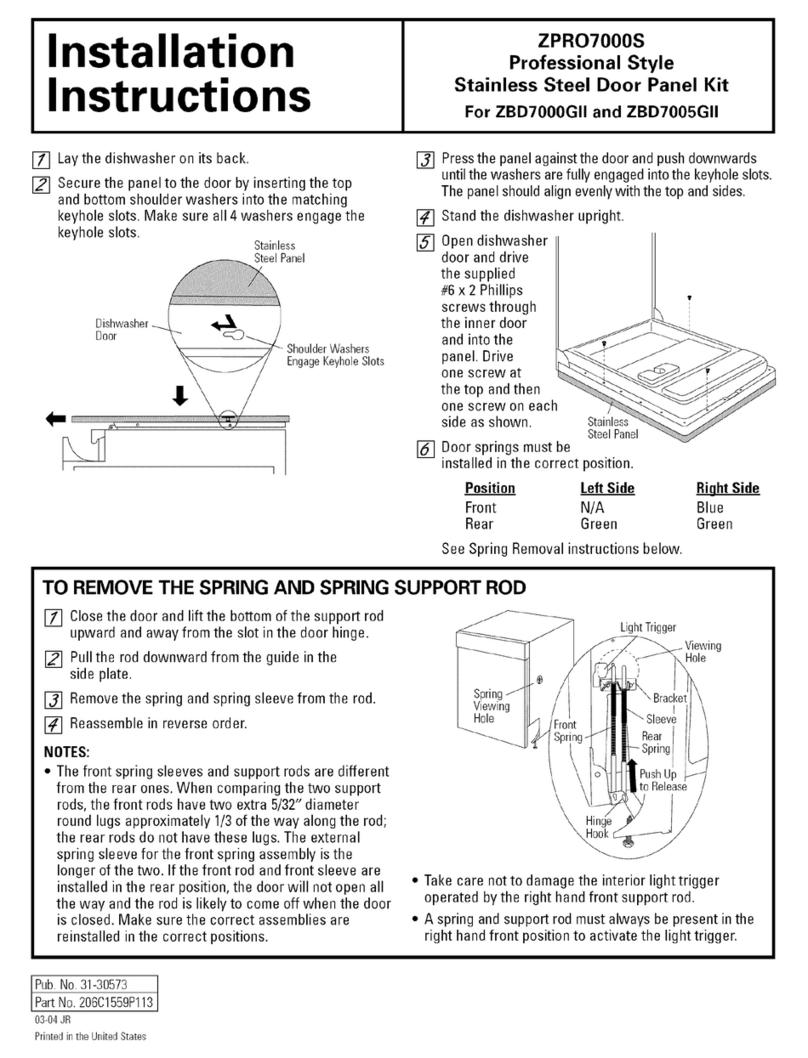

Figure 8: Economizer Actuator and Interface Board -

Diagrams

Configuring the Sensor

The sensor has two different settings:

•User Adjustable Sensor Settings

•Factory Settings

User Adjustable Sensor Settings

The GE Telaire 8000 series includes features which are user adjustable.

These adjustments can be made using the keypad on display units, or by

the PC based UIP program that communicates to the sensor via a custom

RS232 interface cable.

Factory Settings

The default settings are the typical settings used by a building control

system.

If the installation requires changes to the sensor, the user can customize

certain characteristics of the sensor. For example, non-factory settings

may be applicable when the sensor is being connected to equipment that

has a fixed input range (e.g., actuators used with economizer systems).

Sensor Programming Features

Outlined below in Table 1 are the adjustable parameters of the sensor

and the factory setting. In addition to offering these adjustable features,

the programming interface allows for a fast and simple adjustment of

sensor calibration.

All GE Telaire 8000 series products are calibrated at sea level. As

altitude increases, the accuracy of this sensor, as of all gas sensors,

introduces an error of approximately -3% of the reading per 1,000 ft of

elevation. Users that are in elevations significantly higher than sea level,

such as Denver, Colorado, should consider adjusting the altitude to have

the most accurate reading. The altitude setting can be adjusted on the

unit in 500 ft increments.

ABC Logic™ Self Calibration System

All GE Telaire 8000 series sensors are factory set with the ABC Logic

(Automatic Background Calibration) self calibration feature ON. This

feature allows the sensor to continually re-calibrate itself when the

indoor concentrations drop to outside levels while the building is

unoccupied. Generally a building must be regularly unoccupied for 4

hours or more for this self-calibration system to operate properly. Under

these conditions, the ABC Logic feature should maintain sensor

calibration over the lifetime of the sensor. The ABC Logic feature should

be turned OFF where a building is continuously occupied 24 hours per

day, or where there could be significant sources of non-occupant related

CO2such as greenhouses, breweries and other industrial and food

processing applications.

Pre-Programmed Settings

In addition to the factory setting for the 8000 series sensors, nine

standard settings can easily be selected using the keypad (display units

only) or the PC based UIP Program. Table 2 on the next page describes

each of the settings. The definitions for some of the terms used in the

table are described in more detail as part of the custom settings outline in

the “Custom Settings” section on the next page.

Settings 1, 2 and 3 are applicable for automated or computerized

building control systems.

Settings 4 to 7 are specifically designed for operation with economizer

controls and actuators where a 0-10 VDC signal will provide 0-100%

outside air modulation. These control settings provide different

modulation ranges, depending on the target cfm-per-person ventilation

rate desired. As described below, the exponential setting is best used in

applications that have large volumes of air and people, such as

auditoriums, gyms and large conference areas.

Setting 8 is for use in occupational health and safety applications where

users want to measure concentrations in relation to the 5000 ppm, 8 hour

exposure levels established by OSHA (Occupation Safety and Health

Administration).

M100E

8T2

T1

L1

L2

S2

S1

B

R

T

A91MixedAir

Thermistor

9

10

Open

Close

Y45AA-9Remote Minimum

Position Potentiometer

(1,000-10,000 ohm)

L1

L2

Common

1

2

Input

12

3

4

5

6

78

Common

Ventostat MountingBracket

Johnson Controls M100E Economizer Actuator with R81EAA-2

Interface Board

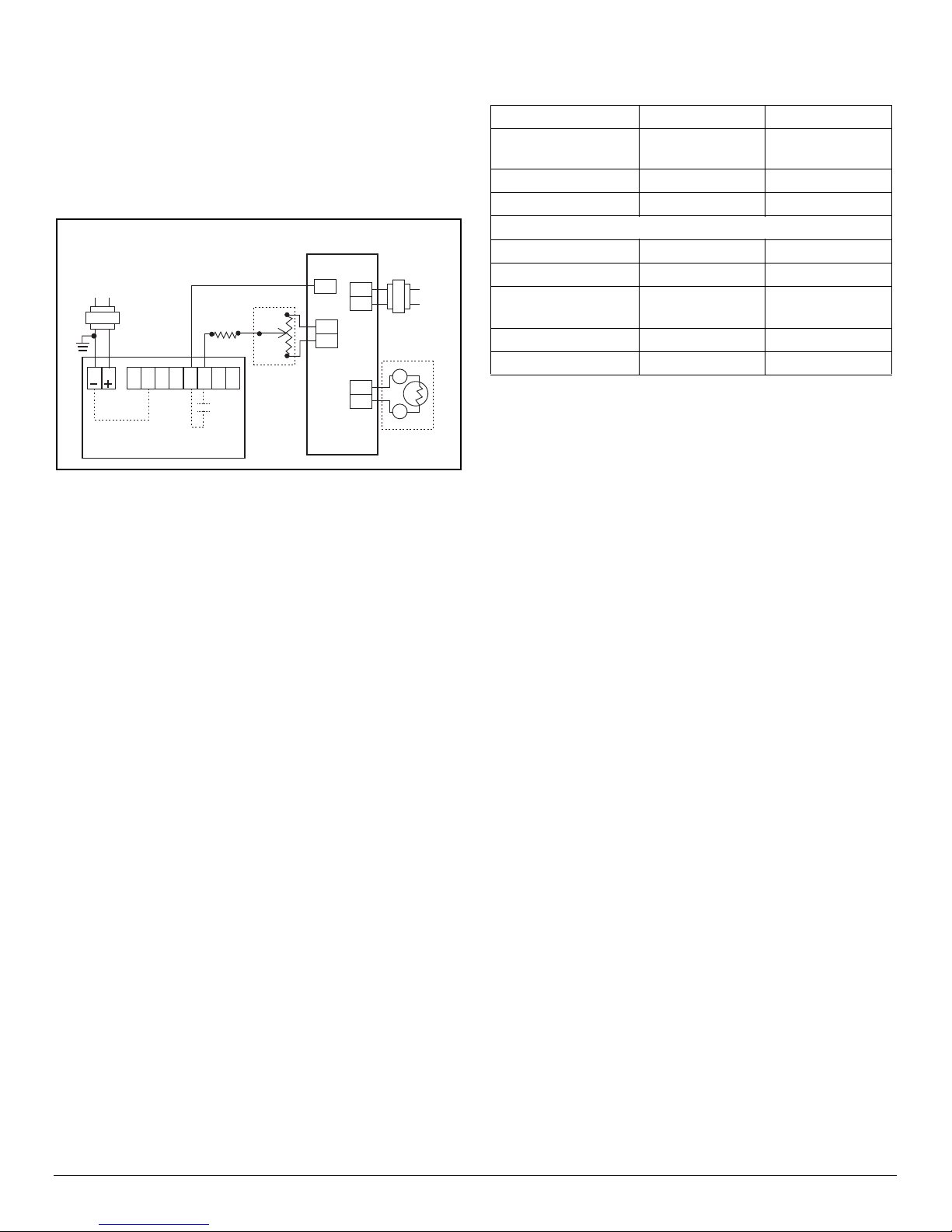

Table 1: 8000 Series Adjustment Parameters and

Factory Settings

Adjustment Range Factory Setting

Altitude Above Sea

Level

0 - 10,000 ft. 0 ft.

ABC Logic™ ON/OFF ON

Select Standard Setting 1 to 9 1

Customize Setting:

PPM Range 0 - 10,000 0-2,000

Output Range 4-20 mA/ 0 - 10 V 4 - 20 mA/ 0-10 V

Proportional/

Exponential Output

Select One Proportional

Relay Setpoint 0 - 10,000 PPM 1000 PPM

Relay Hysteresis 0 - 10,000 PPM 50 PPM