- 4 -

44104

U

N

A

Ap

pp

pl

li

ic

ca

at

ti

io

on

n

N

No

ot

te

e

AN400

© Dukane Corporation 2004. All rights reserved.

Dukane Corporation

2900 Dukane Drive Saint Charles, IL 60174 USA

Phone (630) 797-4900 FAX (630) 797-4949

http://www.dukane.com/us

Intelligent Assembly Solutions

4

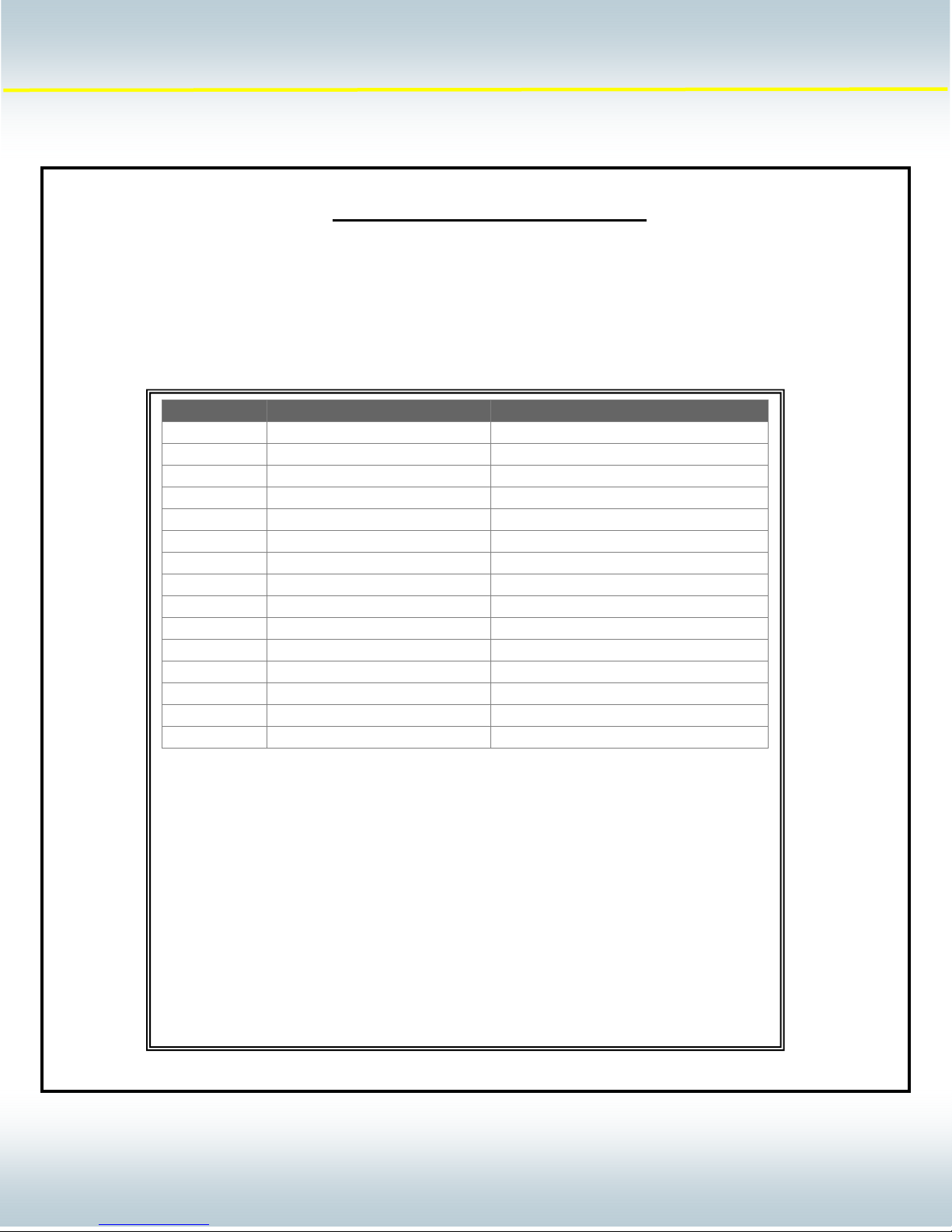

Status Output Signal Descriptions:

Bad Part Output – (J602 pin 3) This status output will activate when the data acquired during the welding sequence

exceeds one of the user defined boundaries within the Bad Part Limits portion of the user setup.

Please refer to the Process Limits section of the DPC IV manual for further details on selecting

and setting up a Bad Part Limit window.

Good Part Output - (J602 pin 5) This status output will activate when the data acquired during the welding sequence

does not exceed any of the user defined boundaries within the Bad Part Limits portion of the user

setup. Please refer to the Process Limits section of the DPC IV manual for further details on

selecting and setting up a Bad Part Limit window.

Suspect Part Output - (J602 pin 4) This status output will activate when the data acquired during the welding sequence

exceeds one of the user defined boundaries within the Suspect Part Limits portion of the user

setup. Please refer to the Process Limits section of the DPC IV manual for further details on

selecting and setting up a Suspect Part Limit window.

In Cycle (J602 pin 4 redefined) - This status output will activate when the welding cycle begins. If

the status outputs have been set for maintained, In Cycle will deactivate when the Hold portion of

the welding cycle has completed. Please refer to the Hardware Setup section of the DCP IV

manual for further details on redefining J602 pin 4.

Sonics On (J602 pin 4 redefined) – This status output will activate when the DPC produces the

ultrasound welding signal that creates motion in the transducer stack assembly. Activation of this

signal will occur during the Weld, Scrub, and Afterburst portions of the weld cycle. Please refer to

the Hardware Setup section of the DCP IV manual for further details on redefining J602 pin 4.

In Hold (J602 pin 4 redefined) – This status output will activate when the DPC is processing the

Hold portion of the welding cycle. Please refer to the Hardware Setup section of the DCP IV

manual for further details on redefining J602 pin 4.

Ready Output - (J602 pin 6) This status output will activate at the completion of the Hold portion of the welding

sequence. It should be noted that the activation of the Afterburst feature and the return of the

pneumatic press to the home position will occur after the activation of the Ready Output status

signal. Please refer to the Process Control section of the DPC IV manual for further information

on the activation and use of the Afterburst feature. In addition please refer to the Hardware Setup

section of the DCP IV manual for further details on redefining J602 pin 6.

Network Active (J602 pin 6 redefined) – This status output will activate when the DPC is an active

node on a DPC network. Please refer to the Network section of the DPC IV manual for further

details on setting up a DPC network. Please refer to the Hardware Setup section of the DCP IV

manual for further details on redefining J602 pin 6.

Sonics On (J602 pin 6 redefined) – This status output will activate when the DPC produces the

ultrasound welding signal that creates motion in the transducer stack assembly. . Please refer to

the Hardware Setup section of the DCP IV manual for further details on redefining J602 pin 6.