3

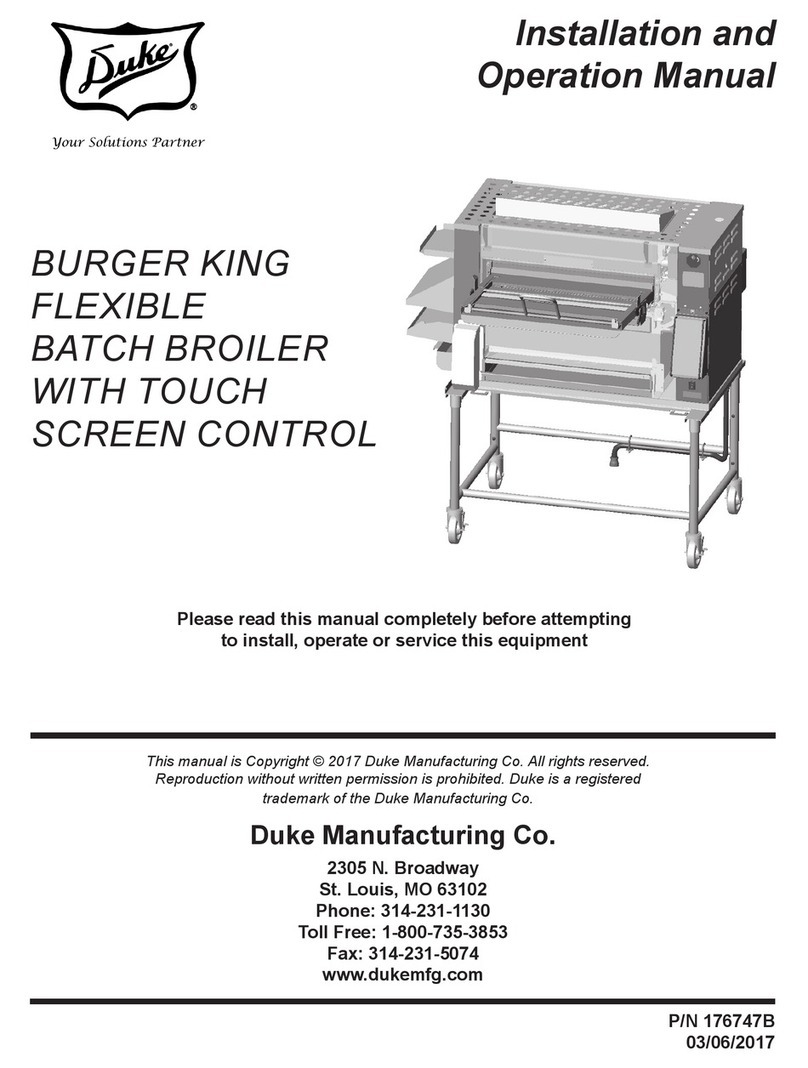

Installation and Operation of Flexible Batch Broiler – Electric

TABLE OF CONTENTS

I. General Information......................................................................................................................5

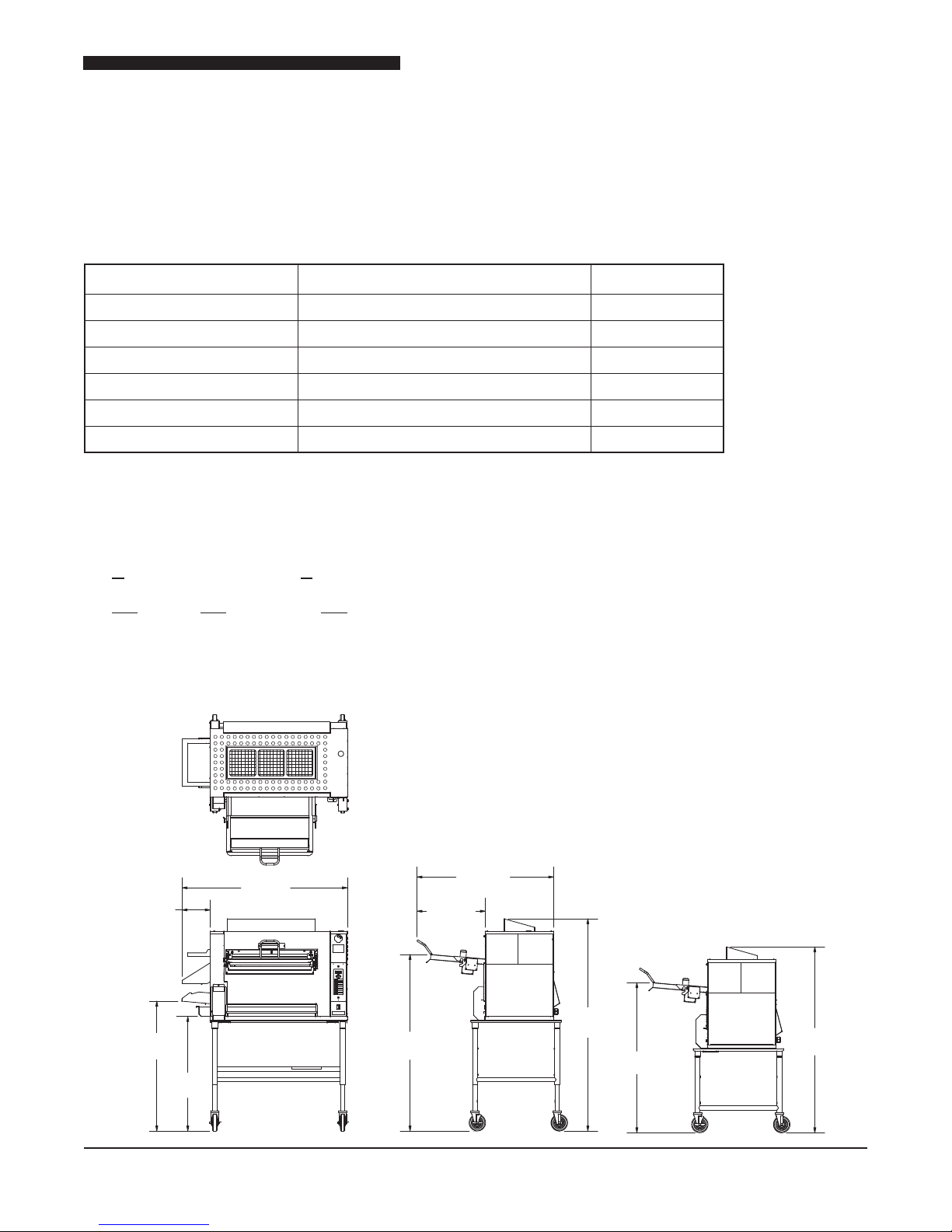

A.BatchBroilerSpecications................................................................................................. 5

A-1.0 Model Number Key................................................................................................. 5

A-2.0BroilerDimensions ................................................................................................ 5

II.InstallationInstructions................................................................................................................6

A.QualiedPersonnel............................................................................................................. 6

B.DeliveryandInspection....................................................................................................... 6

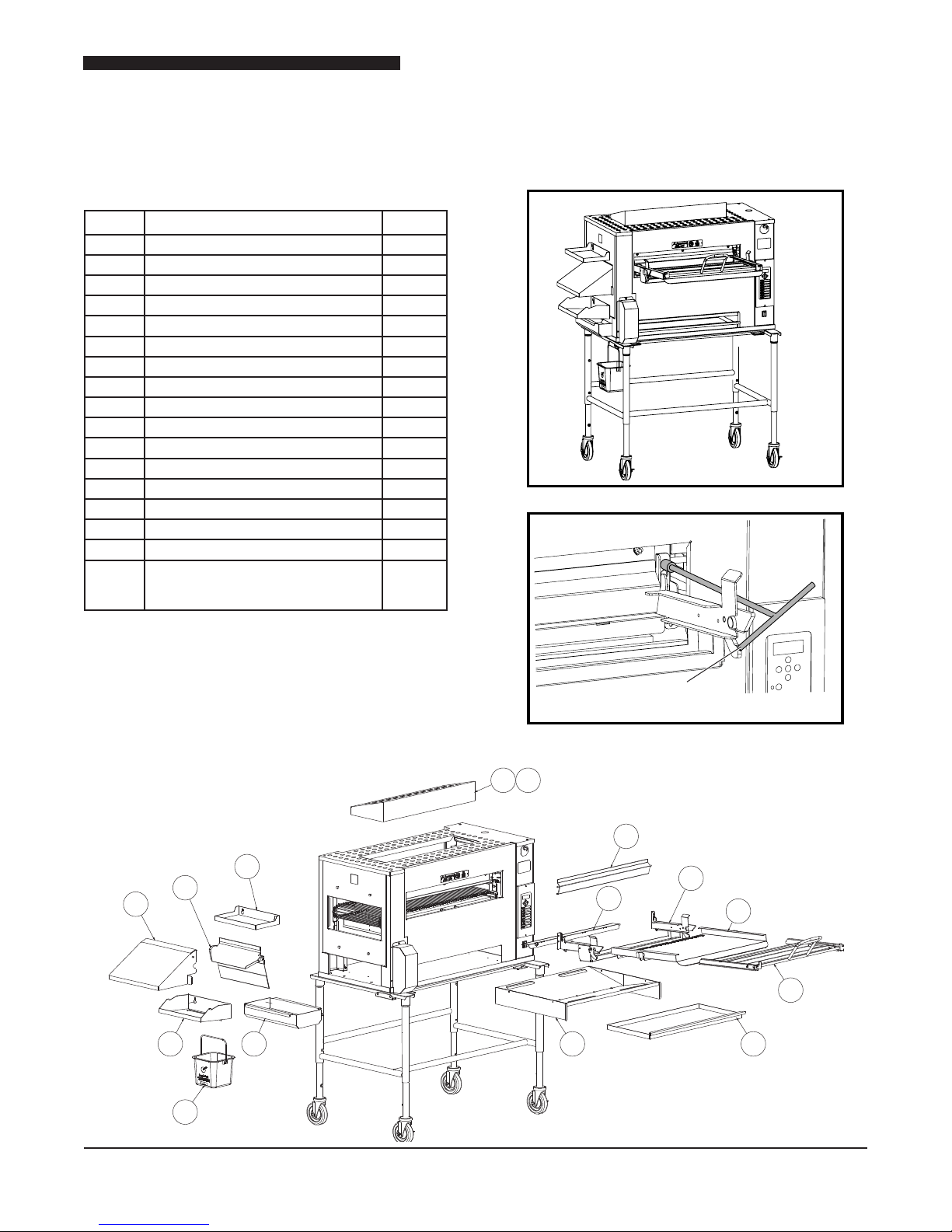

C.BroilerAssembly ................................................................................................................. 7

Setup................................................................................................................................ 7

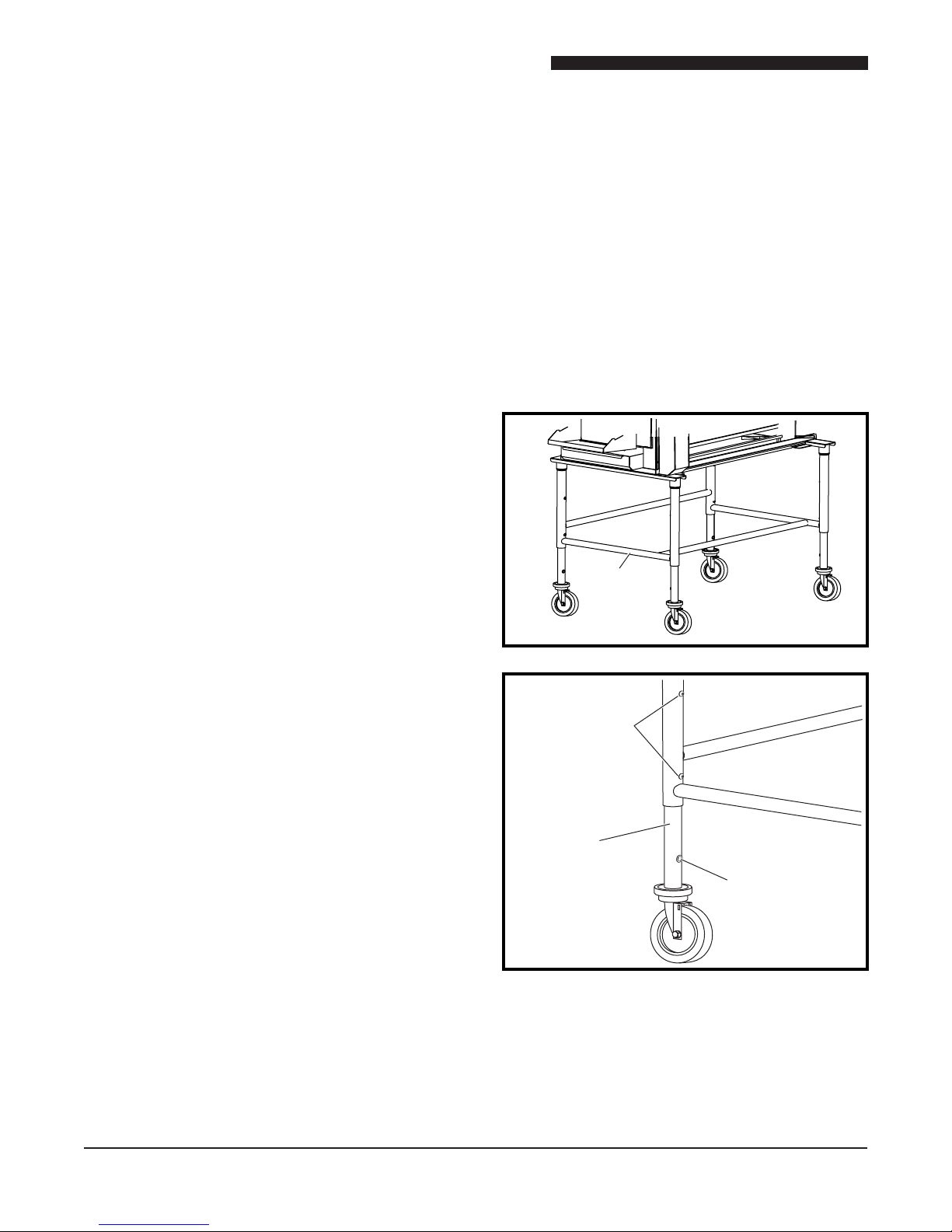

D.AdjustmentsatInstallation .................................................................................................. 8

RaiseorLowerBroiler .................................................................................................... 8

E.LocationoftheBroiler ......................................................................................................... 9

F.ElectricalConnections ......................................................................................................... 9

G. Ventilation ........................................................................................................................... 9

VentingtoaCanopyExhaustHood ................................................................................. 9

MaintenanceofVentilationSystem.................................................................................. 9

III.OperationInstructions ..............................................................................................................10

A.BroilerControls................................................................................................................. 10

B. Cooking Product.............................................................................................................. 11

B-1.0 Turning On the Broiler .......................................................................................... 11

B-2.0 Cook Product........................................................................................................ 11

B-3.0 Cook Cycle Complete........................................................................................... 12

B-4.0FineCookingAdjustment ..................................................................................... 12

B-5.0 Cancel a Cook Cycle............................................................................................ 12

B-6.0 Checking the Broiler Temperature........................................................................ 12

B-7.0 Checking the Set Point Temperature.................................................................... 12

B-8.0ShutdowntheBroiler ............................................................................................ 12

C. Cleaning.......................................................................................................................... 12

C-1.Four(4)HourCleaning ......................................................................................... 14

C-2. Daily Cleaning ........................................................................................................ 15

C-3. Weekly Cleaning ................................................................................................... 17

D. Programming the Control.................................................................................................. 20

D-1.0 Entering Program Mode ....................................................................................... 20

D-2.0NavigatingtheProgrammingScreens ................................................................ 20

D-3.0Level1Programming ......................................................................................... 20

D-3.1ProductIdentierAbCd ...................................................................................... 20

D-3.2CookingProleti1,SEt1,PL1,ti2,SEt2,PL2,… ................................... 20

D-3.3 Exit Program Mode ............................................................................................. 21

D-4.0Level2Programming ......................................................................................... 21

D-4.1 ºF or ºC Parameter dEg ..................................................................................... 21

D-4.2 Change the Idle Temperature iSEt ...................................................................... 21

D-4.3ChangetheIdlePowerLeveliPL........................................................................ 21

D-4.4ChangetheIHeatingElementVoltageSettingCSEn ........................................ 21

D-4.5AdditionalFactoryParameters ............................................................................. 21

D-4.6 Exit Program Mode ............................................................................................. 21

E.Troubleshooting................................................................................................................. 22

IV. Service and Repair...................................................................................................................23

A.Warnings ........................................................................................................................... 24

B.UserReplaceableHeatingElements ................................................................................ 24

V.ReplacementPartsList .............................................................................................................28

VI. Wiring Schematic ..................................................................................................................... 30