7

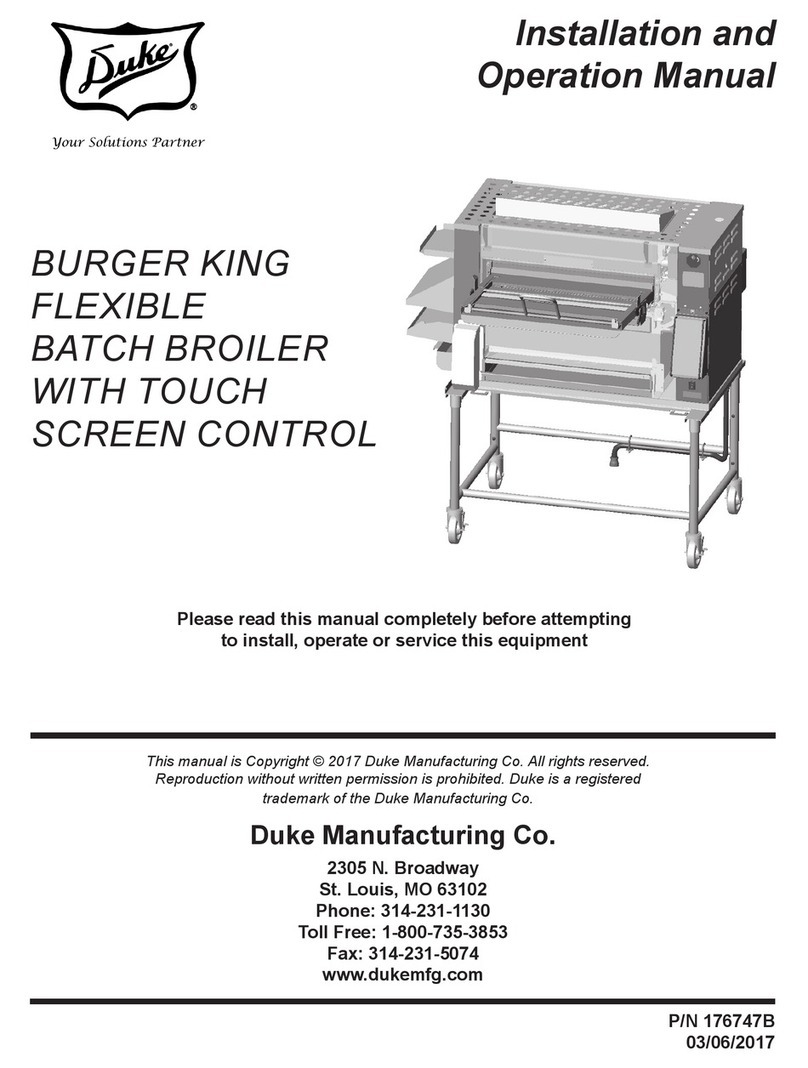

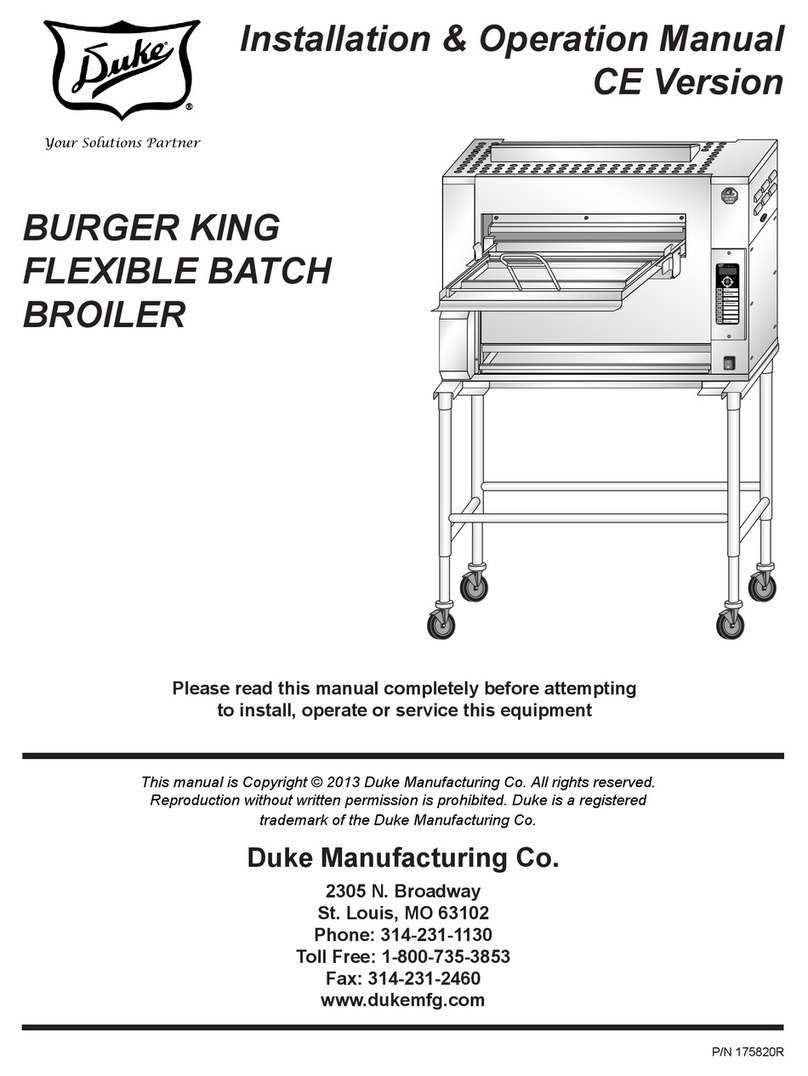

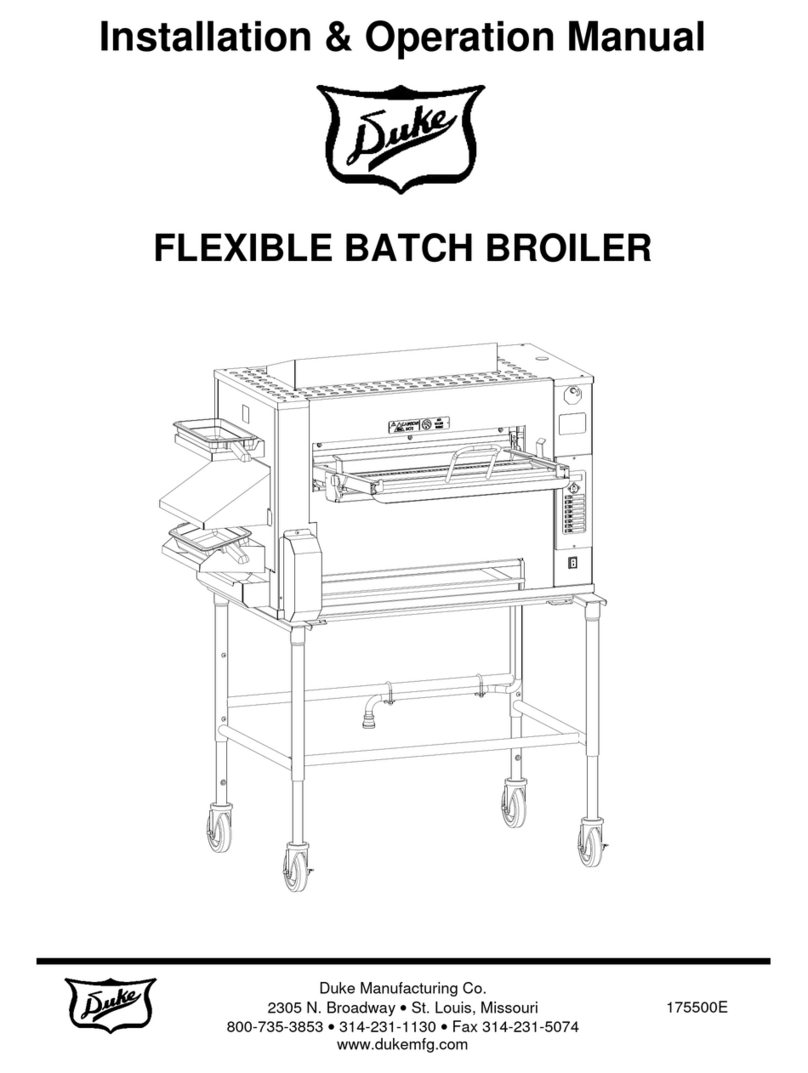

Installation and Operation of Flexible Batch Broiler

II. INSTALLATION INSTRUCTIONS

A. QUALIFIED PERSONNEL

Theseinstallationinstructionsarefortheuseofqualied

installation and service personnel only. Installation or

servicebyotherthanqualiedpersonnelmayresultin

damage to the broiler and/or injury to the operator.

Qualied installation personnel are those individuals,

rms,companiesorcorporationswhicheitherinpersonor

through an agent is engaged in and responsible for:

• The installation or replacement of gas piping or

theconnection,installation,repairorservicingof

equipment, who are experienced in such work,

familiar with all precautions required, and have

complied with all requirements of state and local

authorities having jurisdiction. See: National Fuel

Gas Code NFPA 54 (ANSI Z223.1).

• The installation of electrical wiring from the electric

meter, main control box or service outlet to the

electricalappliance.Qualiedinstallationpersonnel

must be familiar with all precautions required and

have complied with all requirements of state and

local authorities having jurisdiction. See: National

ElectricalCode,ANSI/NFPA70.

• This appliance is not intended for use by persons

(includingchildren)withreducedphysical,sensory

or mental capabilities, or lack of experience

and knowledge, unless they have been given

supervision or instruction concerning use of

the appliance by a person responsible for their

safety.

Theinstallationmustconformwithlocalcodes,orin

theabsenceoflocalcodes,withtheNationalFuelGas

Code,ANSIZ223.1/NFPA54,ortheNaturalGasand

PropaneInstallationCode,CSAB149.1asapplicable,

including:

• The appliance and its individual shutoff valve must

be disconnected from the gas supply piping system

during any pressure testing of that system at test

pressures in excess of ½ psi (3.5 kPa).

• The appliance must be isolated from the gas supply

piping system by closing its individual manual

shutoff valve during any pressure testing of the

gas supply piping system at test pressures equal

to or less than ½ psi (3.5 kPa).

For a broiler mounted on casters, the installation

shall be made with a connector that complies with the

StandardforConnectorsforMovableGasAppliances,

ANSI Z21.69/CSA 6.16 and a quick-disconnect device

that complies with the Standard for Quick-Disconnect

DevicesforUsewithGasFuel,ANSIZ21.4/CSA6.9.

When installing the broiler with casters and quick-

disconnecthose,adequatemeansmustbeprovided

to limit the movement of the broiler without depending

on the connector and the quick disconnect device or

its associated piping to limit the broiler movement. A

means for restraining may be attached to the vertical

portion of the base frame in the rear of the broiler.