vi

DUKE Model 957R Soft Serve Freezer

TT

TT

TABLE OF CONTENTSABLE OF CONTENTS

ABLE OF CONTENTSABLE OF CONTENTS

ABLE OF CONTENTS

SAFETYSAFETY

SAFETYSAFETY

SAFETY ............................................................................................................................................................................................................................

............................................................................................................................................................................................................................

.............................................................................................................. ii

ii

i

SAFETY DECAL LOCATIONSSAFETY DECAL LOCATIONS

SAFETY DECAL LOCATIONSSAFETY DECAL LOCATIONS

SAFETY DECAL LOCATIONS ..........................................................................................................................................................

..........................................................................................................................................................

............................................................................. iviv

iviv

iv

PP

PP

PARAR

ARAR

ART 1T 1

T 1T 1

T 1

11

11

1INTRODUCTIONINTRODUCTION

INTRODUCTIONINTRODUCTION

INTRODUCTION ............................................................................................................................................................................

............................................................................................................................................................................

...................................................................................... 11

11

1

22

22

2NOTE TO INSTALLERNOTE TO INSTALLER

NOTE TO INSTALLERNOTE TO INSTALLER

NOTE TO INSTALLER ............................................................................................................................................................

............................................................................................................................................................

.............................................................................. 11

11

1

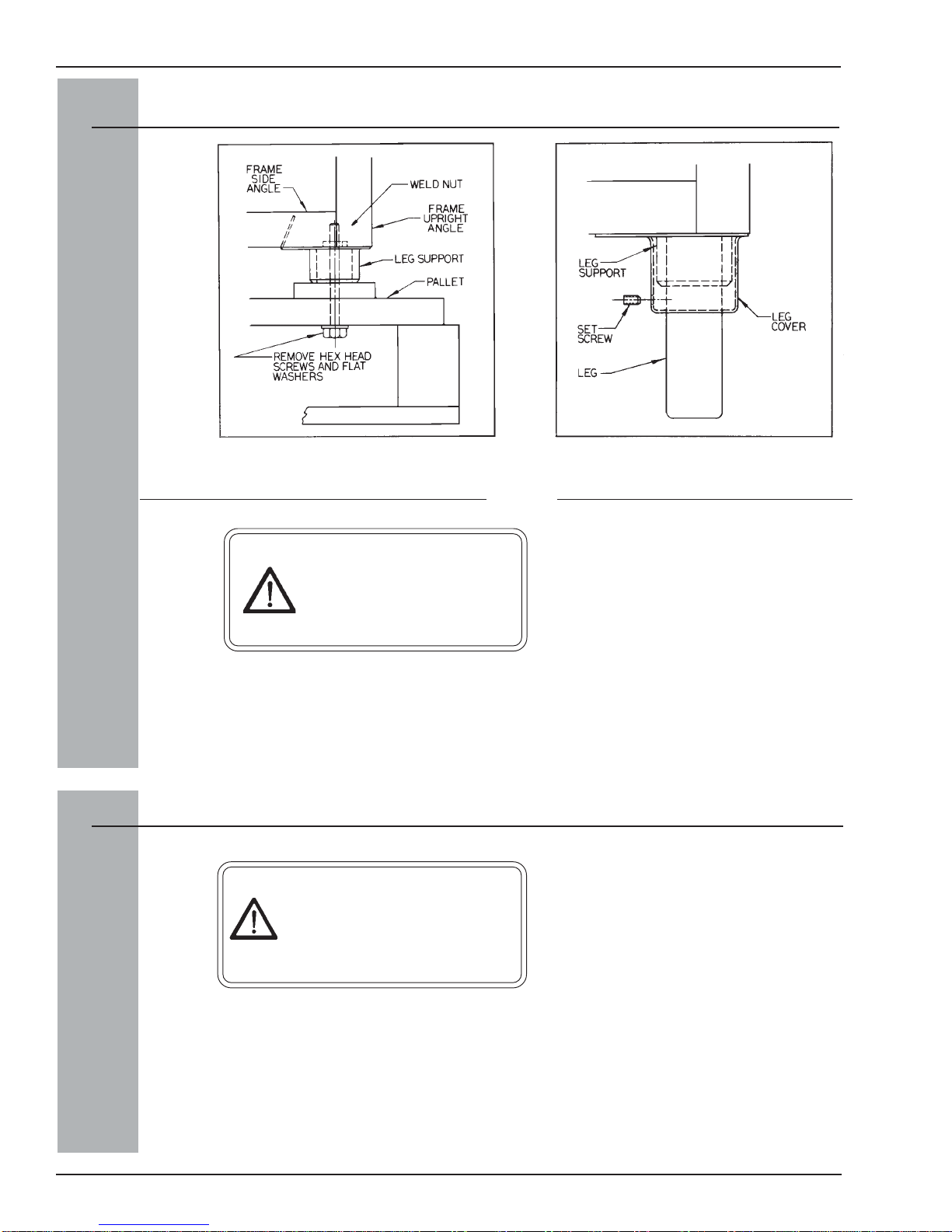

2.1 Uncrating and Inspection2.1 Uncrating and Inspection

2.1 Uncrating and Inspection2.1 Uncrating and Inspection

2.1 Uncrating and Inspection ....................................................................................................................................

....................................................................................................................................

.................................................................. 11

11

1

2.2 Installation2.2 Installation

2.2 Installation2.2 Installation

2.2 Installation ................................................................................................................................................................................

................................................................................................................................................................................

........................................................................................ 22

22

2

2.3ElectricalRequirements2.3ElectricalRequirements

2.3ElectricalRequirements2.3ElectricalRequirements

2.3ElectricalRequirements ..............................................................................................................................................

..............................................................................................................................................

.......................................................................33

33

3

2.4 Electrical Connections2.4 Electrical Connections

2.4 Electrical Connections2.4 Electrical Connections

2.4 Electrical Connections ..................................................................................................................................................

..................................................................................................................................................

.........................................................................33

33

3

33

33

3SPECIFICATIONSSPECIFICATIONS

SPECIFICATIONSSPECIFICATIONS

SPECIFICATIONS ............................................................................................................................................................................

............................................................................................................................................................................

......................................................................................44

44

4

3.1Particulars3.1Particulars

3.1Particulars3.1Particulars

3.1 Particulars ......................................................................................................................................................................................

......................................................................................................................................................................................

...........................................................................................44

44

4

3.2 Dimensions3.2 Dimensions

3.2 Dimensions3.2 Dimensions

3.2 Dimensions ..................................................................................................................................................................................

..................................................................................................................................................................................

.........................................................................................44

44

4

3.3 Data Plate3.3 Data Plate

3.3 Data Plate3.3 Data Plate

3.3 Data Plate ........................................................................................................................................................................................

........................................................................................................................................................................................

............................................................................................44

44

4

44

44

4PART NAMES AND FUNCTIONSPART NAMES AND FUNCTIONS

PART NAMES AND FUNCTIONSPART NAMES AND FUNCTIONS

PART NAMES AND FUNCTIONS ................................................................................................................................

................................................................................................................................

................................................................66

66

6

55

55

5OPERATOR CONTROLSOPERATOR CONTROLS

OPERATOR CONTROLSOPERATOR CONTROLS

OPERATOR CONTROLS ........................................................................................................................................................

........................................................................................................................................................

............................................................................88

88

8

66

66

6DISASSEMBLY AND CLEANINGDISASSEMBLY AND CLEANING

DISASSEMBLY AND CLEANINGDISASSEMBLY AND CLEANING

DISASSEMBLY AND CLEANING ............................................................................................................................

............................................................................................................................

.............................................................. 1111

1111

11

6.1 Cleaning Accessories6.1 Cleaning Accessories

6.1 Cleaning Accessories6.1 Cleaning Accessories

6.1 Cleaning Accessories ................................................................................................................................................

................................................................................................................................................

........................................................................ 1212

1212

12

6.2 Disassembly Instructions6.2 Disassembly Instructions

6.2 Disassembly Instructions6.2 Disassembly Instructions

6.2 Disassembly Instructions ....................................................................................................................................

....................................................................................................................................

.................................................................. 1212

1212

12

6.3 Cleaning Instructions6.3 Cleaning Instructions

6.3 Cleaning Instructions6.3 Cleaning Instructions

6.3 Cleaning Instructions ................................................................................................................................................

................................................................................................................................................

........................................................................ 1414

1414

14

77

77

7ASSEMBLYASSEMBLY

ASSEMBLYASSEMBLY

ASSEMBLY ........................................................................................................................................................................................

........................................................................................................................................................................................

............................................................................................ 1717

1717

17