RFDU Operator’s Manual

2

TABLE OF CONTENTS

TO BE UPDATED

Manufacturer’s Introduction........................................................................................................................................3

Important Safety Instructions.................................................................................................................................. 4-5

Installation.......................................................................................................................................................................6

RFDU Operating Instructions.......................................................................................................................................8

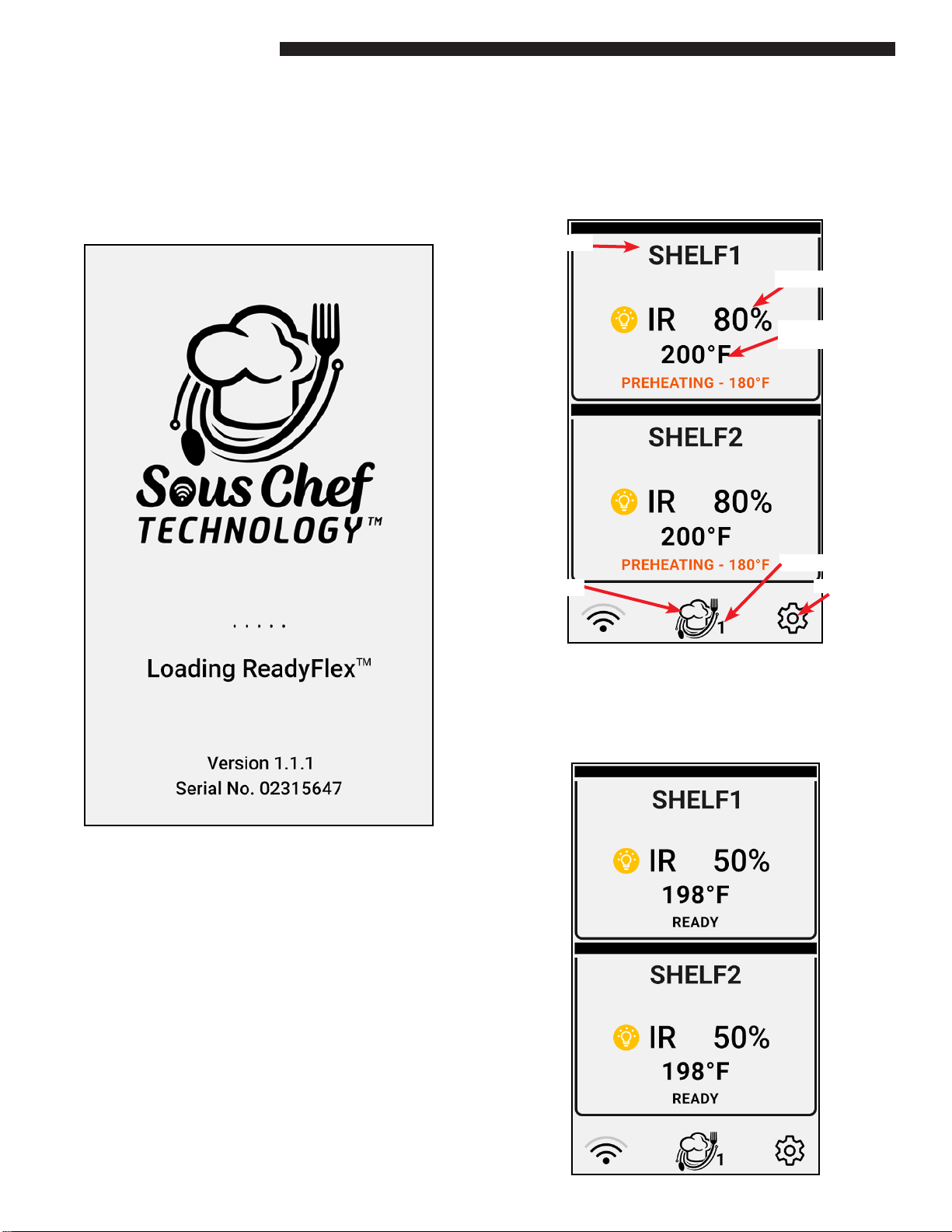

Overview ............................................................................................................................................................................................. 8

Preheating .......................................................................................................................................................................................... 9

Faults..................................................................................................................................................................................................... 9

RFDU Daypart Menu ....................................................................................................................................................................... 9

Settings ..........................................................................................................................................................................10

Menu..................................................................................................................................................................................................10

Temp Mode.......................................................................................................................................................................................10

PHU Congurator...........................................................................................................................................................................10

RFDU Recipe Editor........................................................................................................................................................................11

Language ..........................................................................................................................................................................................11

Help.....................................................................................................................................................................................................11

About..................................................................................................................................................................................................12

Tools Menu........................................................................................................................................................................................12

Network .............................................................................................................................................................................................12

PHU Volume .....................................................................................................................................................................................15

Temperature Display .....................................................................................................................................................................15

Managers Menu..............................................................................................................................................................................15

Access.................................................................................................................................................................................................16

Temp Oset ......................................................................................................................................................................................16

IRDC Period.......................................................................................................................................................................................17

Sous Chel Technology Programming........................................................................................................................18

USB Programming........................................................................................................................................................19

Cleaning Guide .............................................................................................................................................................21

Temperature Check Procedure ..................................................................................................................................23

RFDU Specication.......................................................................................................................................................24

Wire Diagrams ..............................................................................................................................................................25