Page 2

Important:

The installation of the SGF104, commissioning, service and removal must be carried out by

authorized and/or specialized personnel. During installation the sensor enclosure must not be

pierced to do so will compromise the protective rating protection.

The installation of the detector does not exempt the user from compliance with all regulations

concerning the characteristics, installation and use of associated equipment. The ventilation

of the spaces and, for example, the removal of combustion products are described in the UNI

norms such as ART. 3 LAW 1083 / 71 and relevant legal provisions.

Do not allow the sensor to become wet.

The probe can be seriously damaged when immersed in water. Remember that the probe has

an IP64 protection degree.

Handle with care

Heavy knocks or falls during transportation or installation can damage the sensor.

Avoid abrupt temperature uctuations.

Sudden temperature variations can cause condensation and the probe could work poorly. Tem-

perature compenstation is tted to this sensor but rapid changes will still aect the functionality.

Cleaning Never clean the device with chemical products. Absolutely avoid using any cloth dip-

ped in thinners, alcohol and chemical detergents. The outer enclosure should only be cleaned

using a damp cloth.

Power supply ....................................................................................................................... 12÷24 VDC ± 10%

Power demand ...................................................................................... 110 mA in alarm Max @ 13,8 VDC

Relay switching alarm ......................................................................................................... 1 A 30VDC SELV

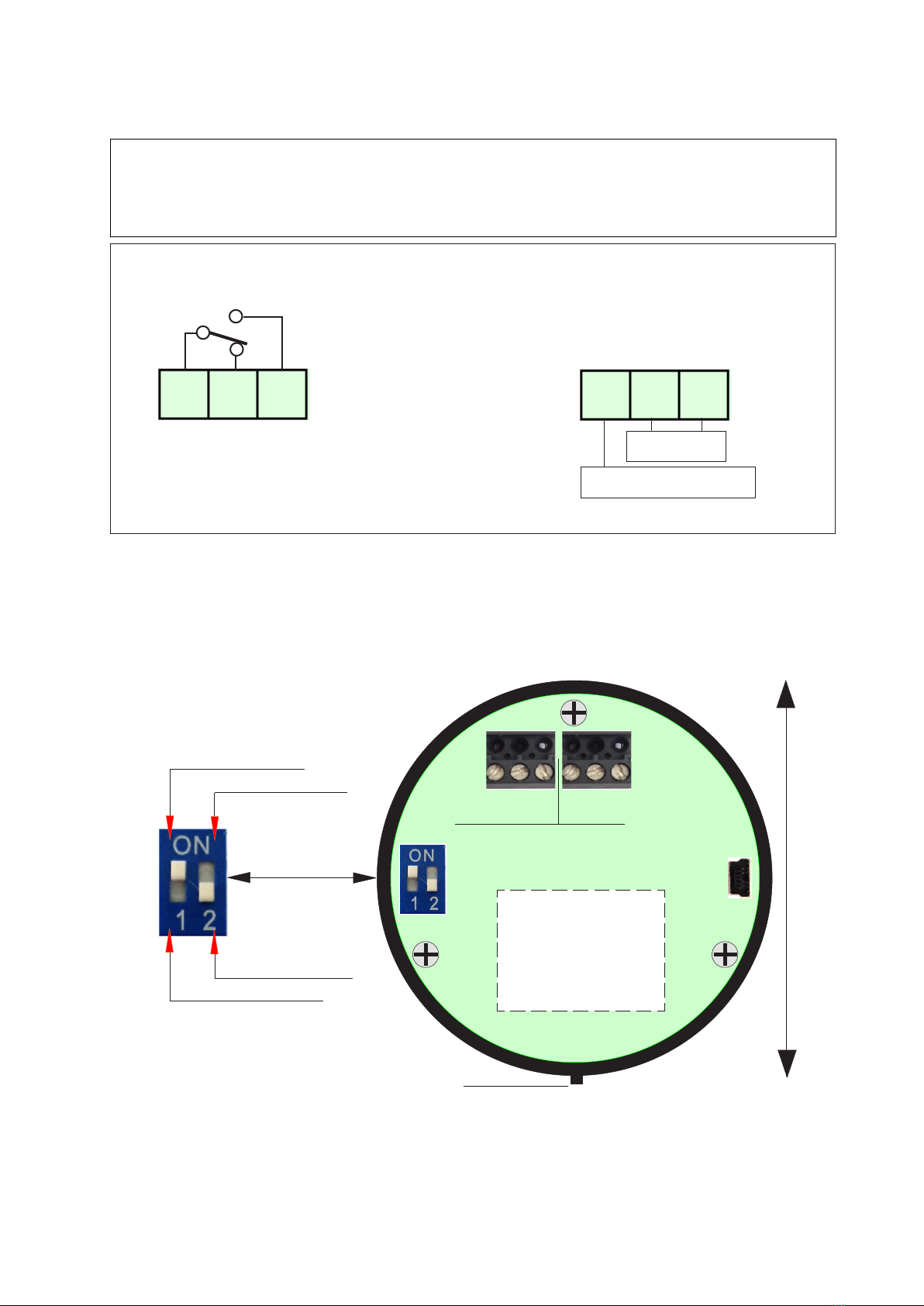

Selection of positive safety........................................................................................ Selectable by switch

Type of gas detected: Oxygen

Integratedsensoraccordingtothetypeofgas...........................................................Opticaluorescence

Operating range of the sensing element ..........................................................................0 - 25 % of O2

Operating range selectable by switch ....................... 19.5 or 18.5% of O2 (depletion), 22.5, 23.5%

of O2 (Excess) Note1

Detector accuracy ...............................................................................................................................+/- 1% FS

Long term shift in clean air ...................................................................................................... < 3% of L.E.L.

Auto zero procedure .................................................................... Included in the software algorithms

ResponseTime ............................................................................................................................................... < 10”

Functioning humidity .............................................................................................. 0-90% not condensed

Functioning temperature ..................................................................................................... -30°C to +60°C

Control units usable directly.................................................................................................... BX308, BX316

Control units usable with adapter code yy.............. BX444-Mc, BX449F, GS100M, BX180, BX280,

BX150, GS300M

Cable diameter for connecting probe - Note2............................................................ 1 mm for 100 mt

Section shielded cable transmission distance up to 500 meters .............................x0,75mm2CSA

Installation...................................................................................................................ceilingorwallmounted

Anti-tamper protection ..................................................................................................................... included

Enclosure.................................................................................................... ABS self-extinguishingVDE0471

External degree of protection........................ IP64

Overall dimensions ...........................................Diameter 90 mm, Depth 45mm

Electromagnetic compatibility Reference Norms ... EN 50270

Note1.

On SGF104 the trigger levels are dependant on the position of the DIP switch 2 selection.

They are respectively 19.5% (depletion) and 22,5% (excess) - DIP2 in OFF position - or 18.5%

(depletion) and 23,5% (excess) - DIP2 in ON position.

Note2.

Connection: The sensor cable must not be installed together with the power cables. If this is

unavoidable it is imperative otherwise, make sure to use a shielded cable.

Technical Specication