3

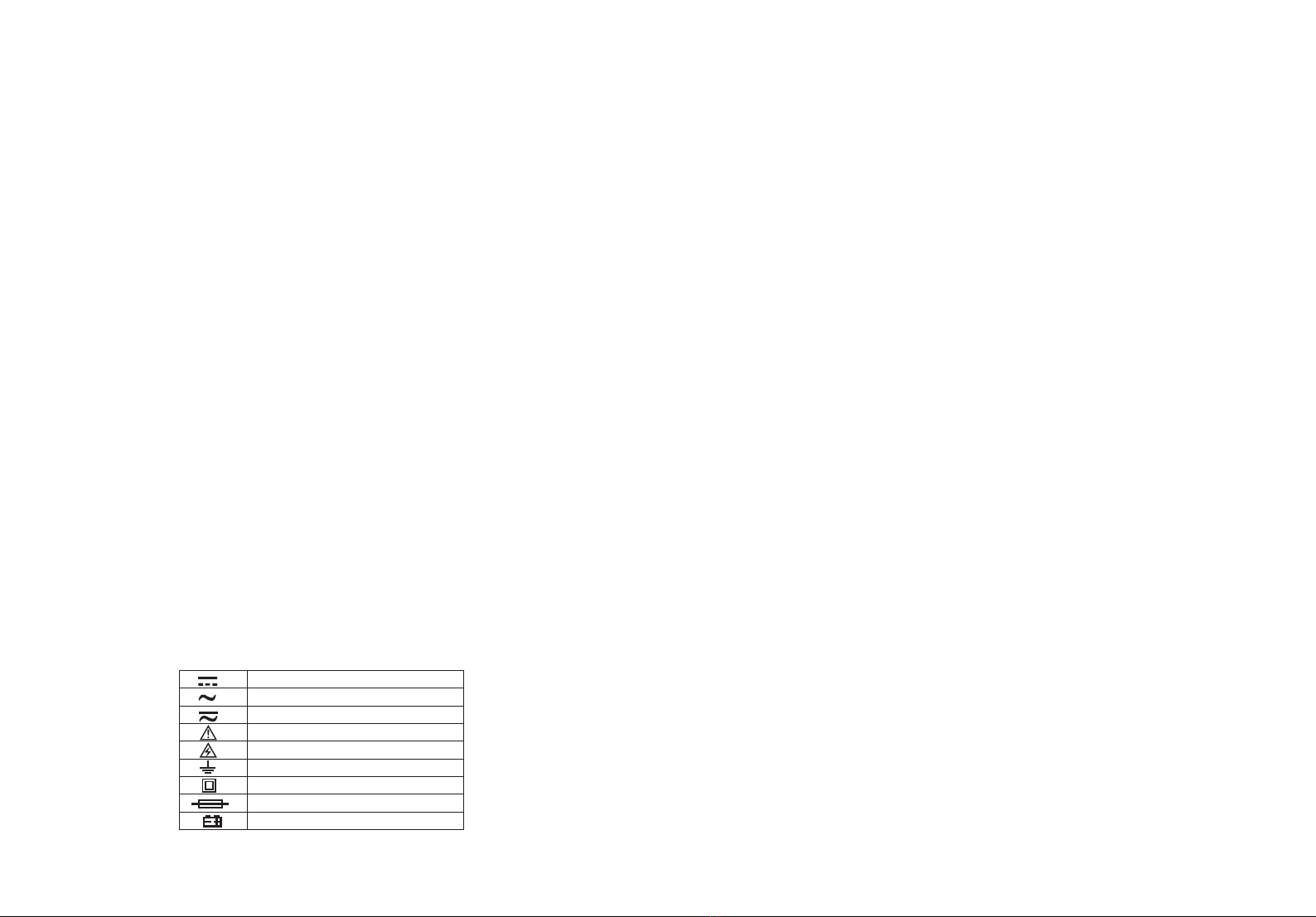

4. Structure of Meter

Introduction of button and clamp

<▲><▼>:increase, decrease,

turn up/down the page

<ESC>:cancel, undo, return

<ENTER>:select, enter, test

the red clamp: positive connection

the black clamp: negative connection

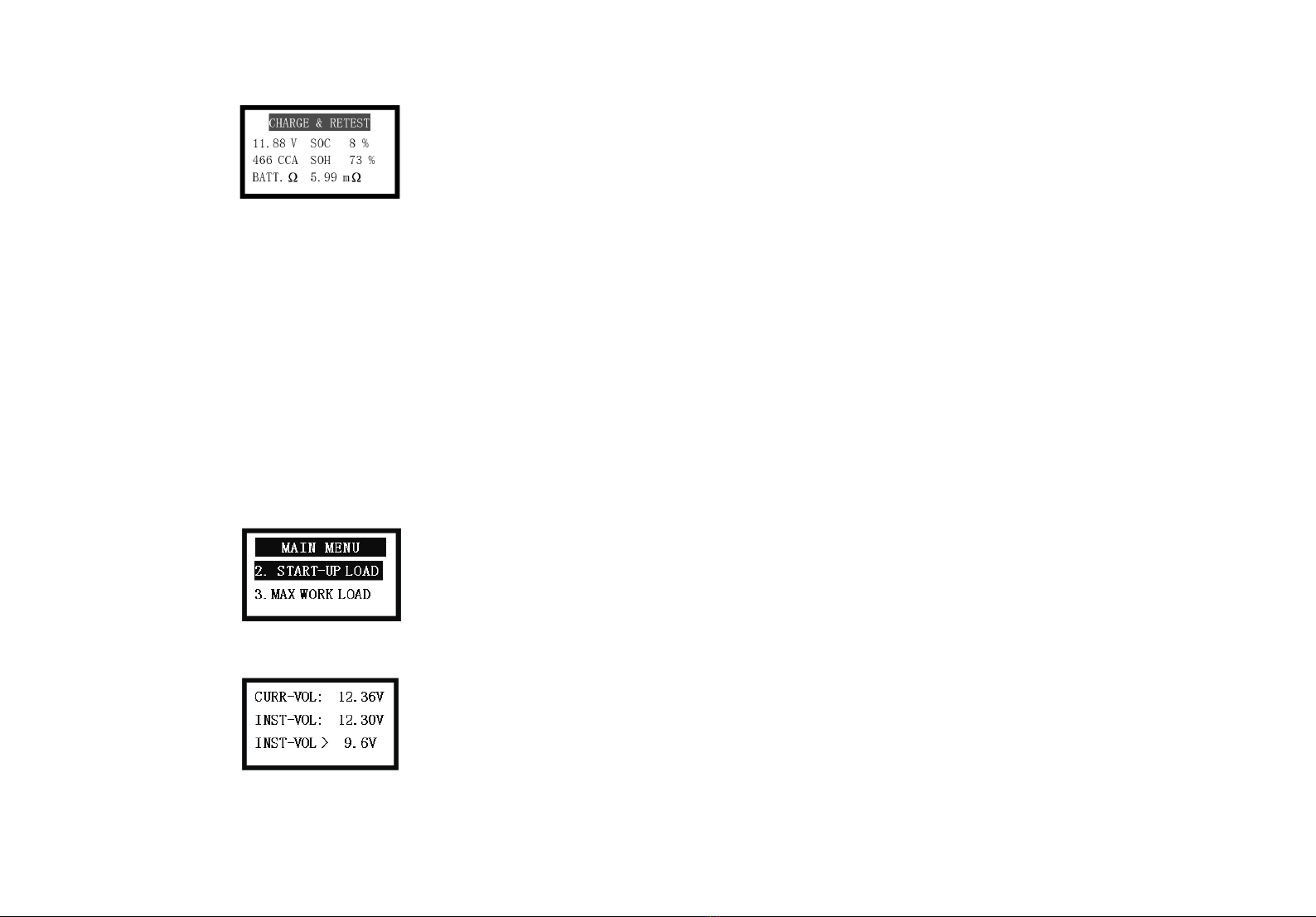

5. Functional Instructions

5-1 storage battery voltage mode setting

Before testing, set the tested voltage according to the type of battery

voltage. Select 12V mode for a 12V battery. Select 24V mode for a 24V

battery. And then head to the following testing :battery capacity test, start-up

load test, maximum load system test, charging system test.

5-2 battery capacity test

Two test methods are available--quick test and accurate test.

Quick test is the method that utilizes roughly calculated CCA transmitted

from capacity value (Ah) listed on the battery label in case of no CCA visible.

Accurate test is the method directly utilizes CCA listed on the battery

label.

PLEASE NOTE : Accurate test is recommended for testing as long as

CCA is available and visible from the battery because CCA value differs even

though the batteries with the same capacity of the same brand.

18

LCD

button

testclamp

8. Knowledge About Automotive Battery

8-1 the internal resistance of different types of battery

differ

The internal resistance differs because of inconformity of internal

chemical feature even if with the same type battery. It is very small so that we

generally define it with unit of milliohm. Internal resistance is a significant

technical standard to measure a battery. Normally the battery with small

internal resistance has a great ability to discharge. On the contrary the

battery with large internal resistance has a little ability to discharge.

8-2 it is unavailable to know the battery's capacity by

intuition

Hydrometer can be used to check the condition of the battery. Battery

water is distilled water and pure sulfuric acid of the proportion of 1.260/20 ℃

to allocate. For a new battery, it is supposed to supply distilled water with

reduction of battery water for the reason that the degree of acid is fixed when

the quantity of battery water remain the normal range. Distilled water

supplement can maintain a certain amount of water, but also the PH value. If

the battery works normally, in addition to the PH is fixed, the proportion of the

value will be in a certain range.

If the battery finishes charging, the proportion of battery water does not

reach 1.26-1.28, along with the tested voltage under 12.7V, the storage

capacity of this battery has descended. It is impossible to recover its life by

deliberately adjusting the proportion to 1.26 (Increase the sulfuric acid

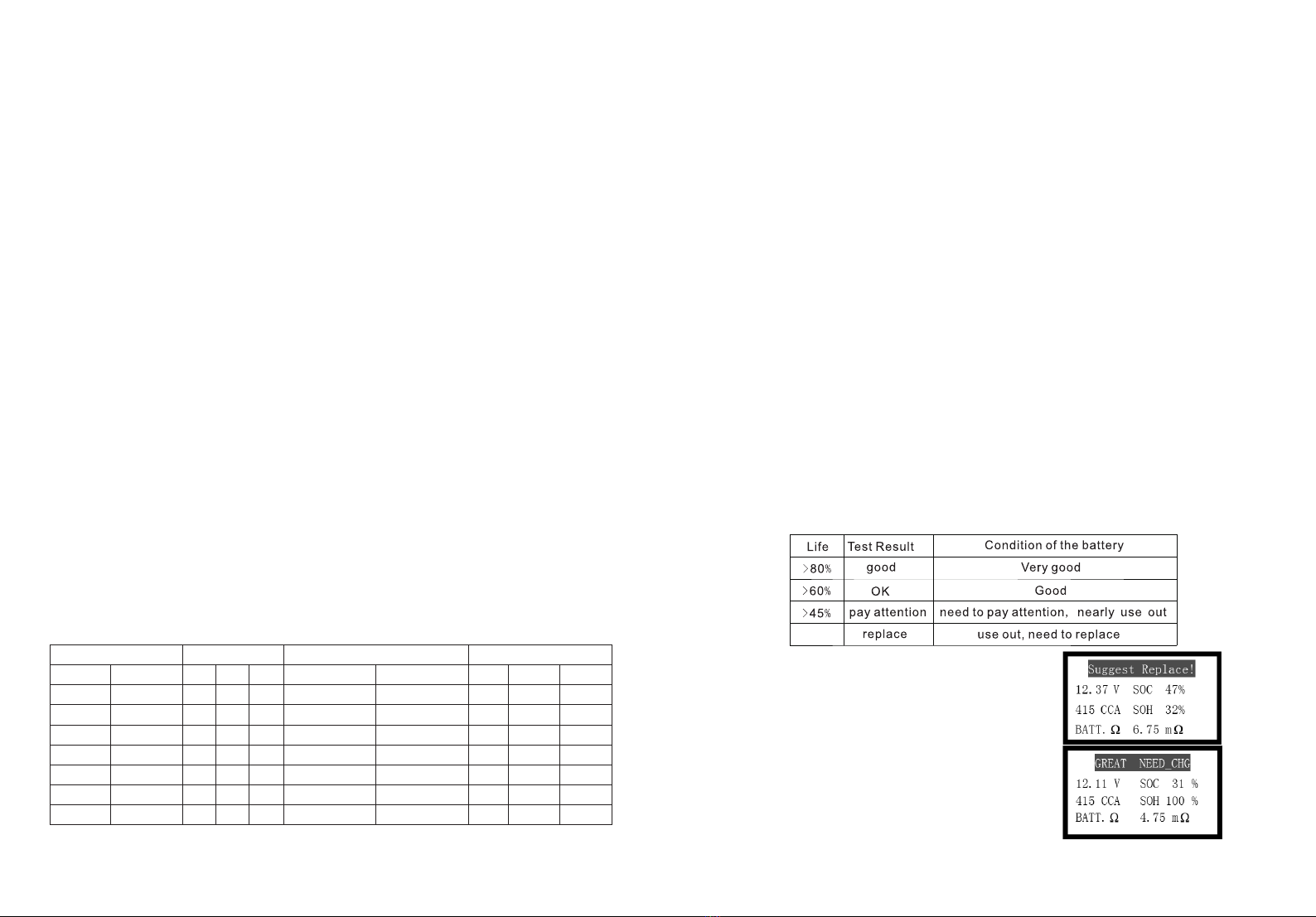

Battery of small type vehicle

Voltage(V)

Electric(%)

Proportion

>12.7

100% 1.26~1.28

12.6

90% 1.2 4

12.4

70~80% 1.22

12.1

50%

1.16

<12 25%<1.13