TABLE OF CONTENTS

Contacts..................................................................................................................................................... 4

Safety instructions......................................................................................................................................... 5

Characteristics ............................................................................................................................................... 6

Features..................................................................................................................................................... 6

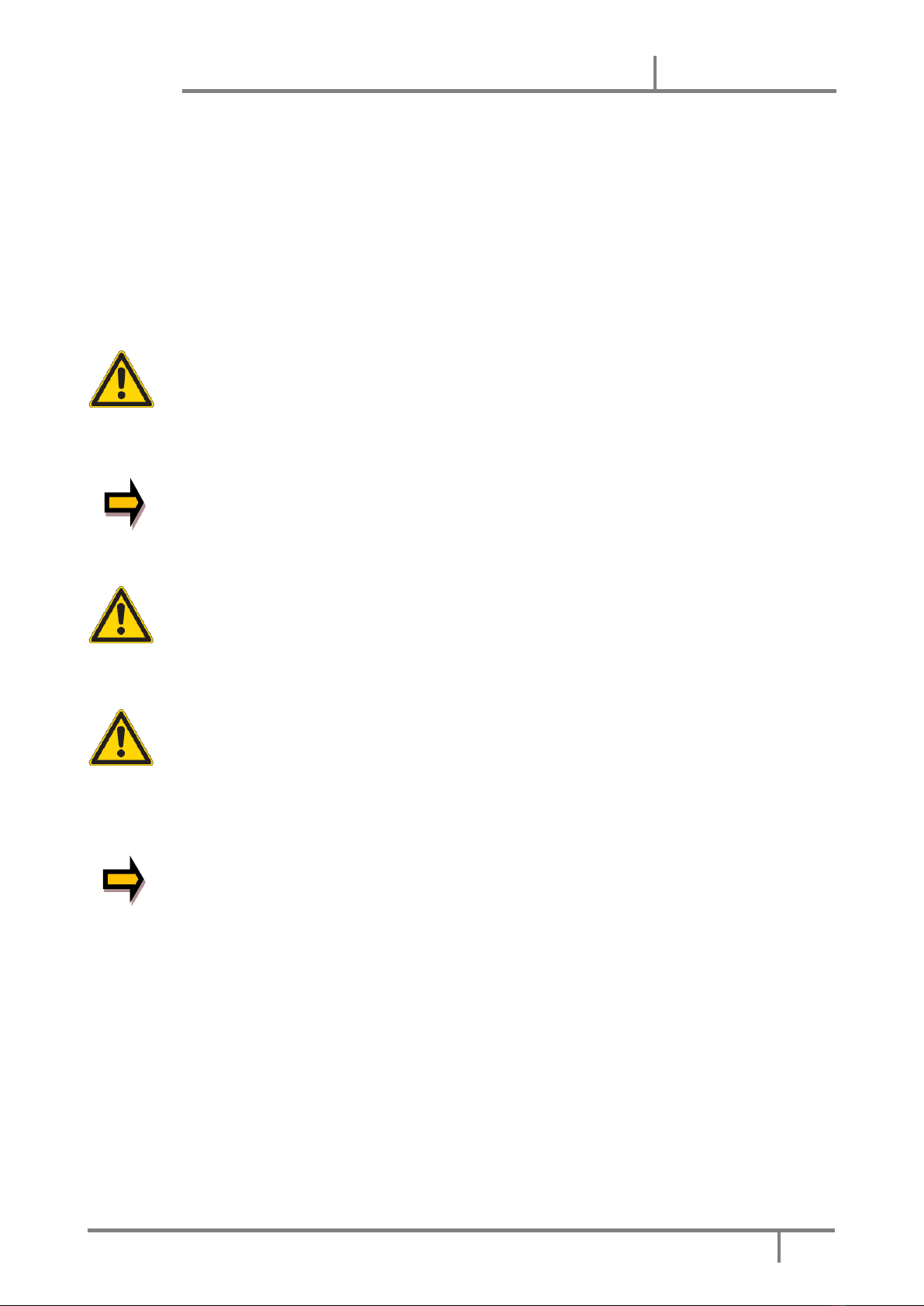

Device description ......................................................................................................................................... 7

USE AND APPLICATION...................................................................................................................................... 8

Installation instructions................................................................................................................................. 8

Typical system structure................................................................................................................................ 9

Method of operation................................................................................................................................... 10

Commissioning ............................................................................................................................................ 12

Technical description....................................................................................................................................... 13

Input and output signals.............................................................................................................................. 13

LED definitions............................................................................................................................................. 14

First section with USB.............................................................................................................................. 14

Second section (fieldbus) ........................................................................................................................ 14

Block diagram .............................................................................................................................................. 15

Typical wiring............................................................................................................................................... 16

Technical data.............................................................................................................................................. 17

Parameters OVERVIEW.................................................................................................................................... 18

Command Description..................................................................................................................................... 21

Basic parameters ......................................................................................................................................... 21

MODE (Switching between parameter groups) ...................................................................................... 21

System parameters (MODE = SYSTEM) ....................................................................................................... 21

LG (Changing the language for the help texts) ........................................................................................ 21

SENS (Malfunction monitoring) .............................................................................................................. 21

PASSFB (Password fieldbus) .................................................................................................................... 22

EOUT (Output signal: READY = OFF) ....................................................................................................... 22

HAND (Manual speed) ............................................................................................................................ 22

POSWIN (in-position monitoring range)................................................................................................. 23

VMODE (Selecting the control mode)..................................................................................................... 23

I/O parameters ............................................................................................................................................ 25

SELECT:X (sensor type) ........................................................................................................................... 25

VRAMP (ramp time for external speed demand).................................................................................... 25

SIGNAL:U (Type and polarity of the output signal) ................................................................................ 25

SYS_RANGE (axes working stroke) .......................................................................................................... 26

SIGNAL (input signal) .............................................................................................................................. 26

N_RANGE:X (nominal range of the sensor) ............................................................................................. 26

OFFSET_x:X (sensor zero correction)...................................................................................................... 26

SSI:POL (direction of the sensor signal).................................................................................................. 27

SSI:RES (signal resolution) ...................................................................................................................... 27

SSI:BITS (number of bits) ........................................................................................................................ 27

SSI:CODE (signal coding) ......................................................................................................................... 27

SSI:ERRBIT (position of the “out of range” bit)....................................................................................... 27

Positioning controller .................................................................................................................................. 28

ACCEL (acceleration in NC mode)............................................................................................................ 28

VMAX (maximum speed in NC mode) ..................................................................................................... 28

V0(loop gain setting) ............................................................................................................................... 28