1Important Notes.............................................................................................................................................. 1

1.1 Product Range......................................................................................................................................... 1

1.2 Target Group ........................................................................................................................................... 1

2 Safety ............................................................................................................................................................. 1

2.1 Important Safety Instructions ................................................................................................................... 1

2.2 Explanation of Symbols ........................................................................................................................... 2

2.3 Radio Interference Statement .................................................................................................................. 2

3 Product Introduction ....................................................................................................................................... 3

3.1 Highlights................................................................................................................................................. 3

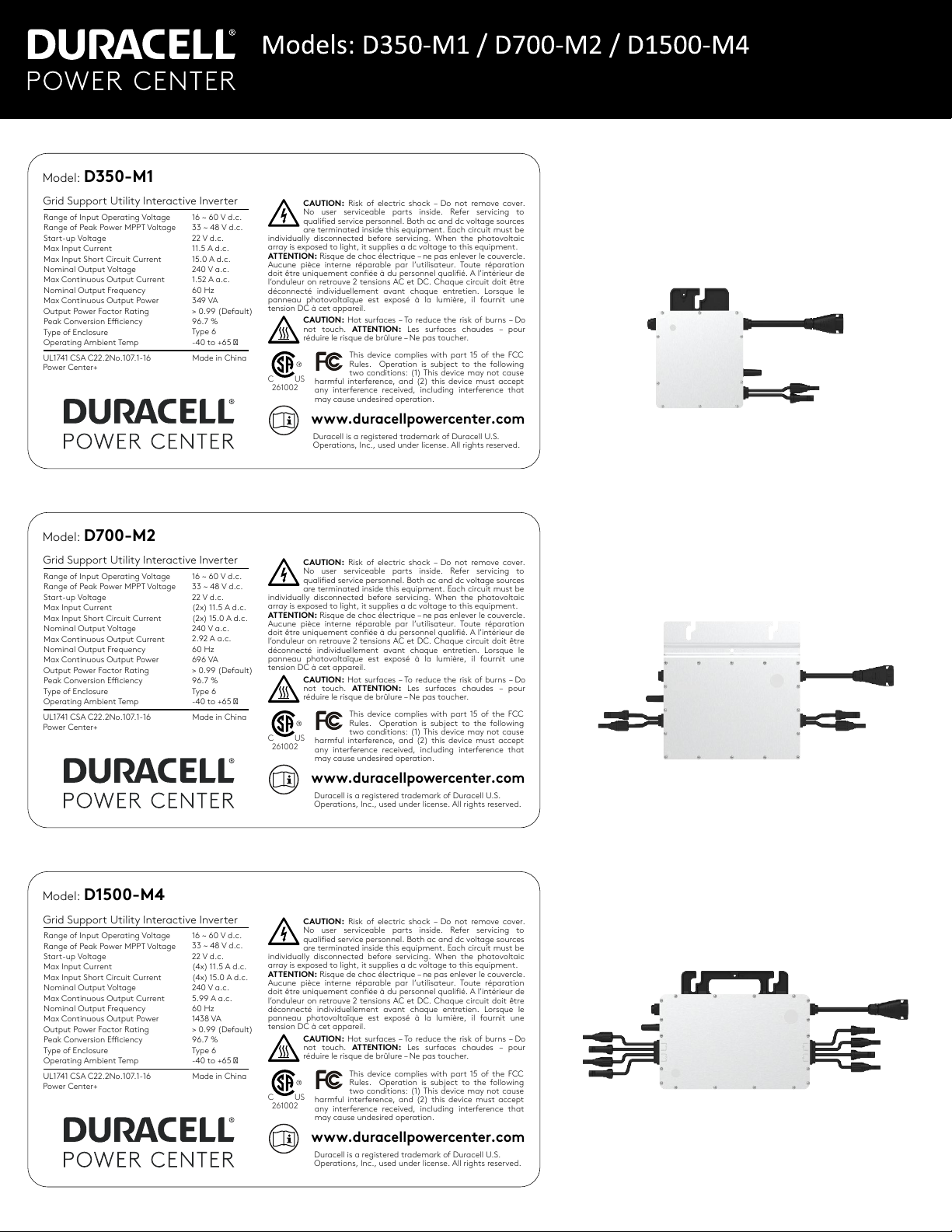

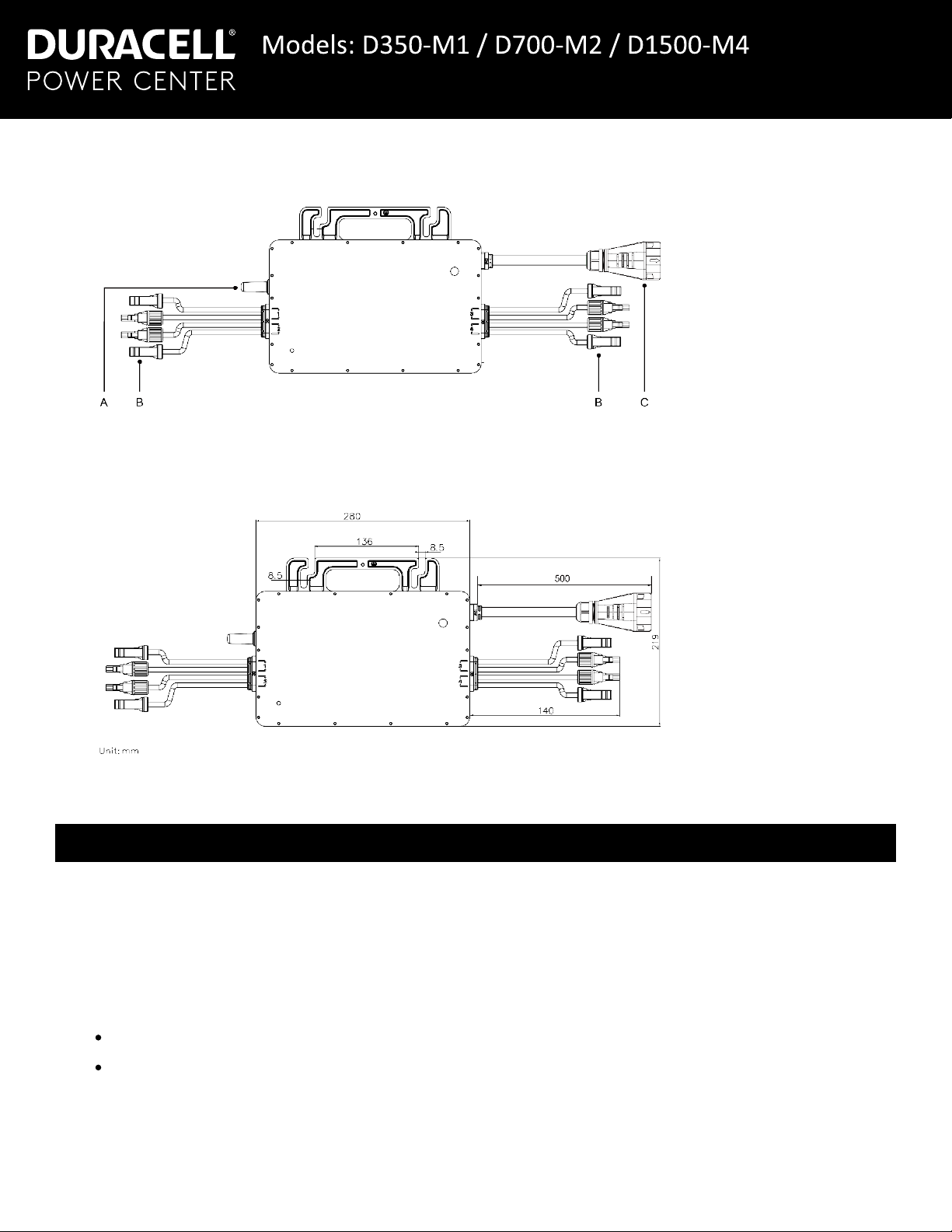

3.1.1 D350-M1: Terminals / Dimensions ...................................................................................................... 3

3.1.2 D700-M2: Terminals / Dimensions ...................................................................................................... 3

3.1.3 D1500-M4: Terminals / Dimensions .................................................................................................... 4

4 Modes of Operation........................................................................................................................................ 4

5Installation Planning ....................................................................................................................................... 5

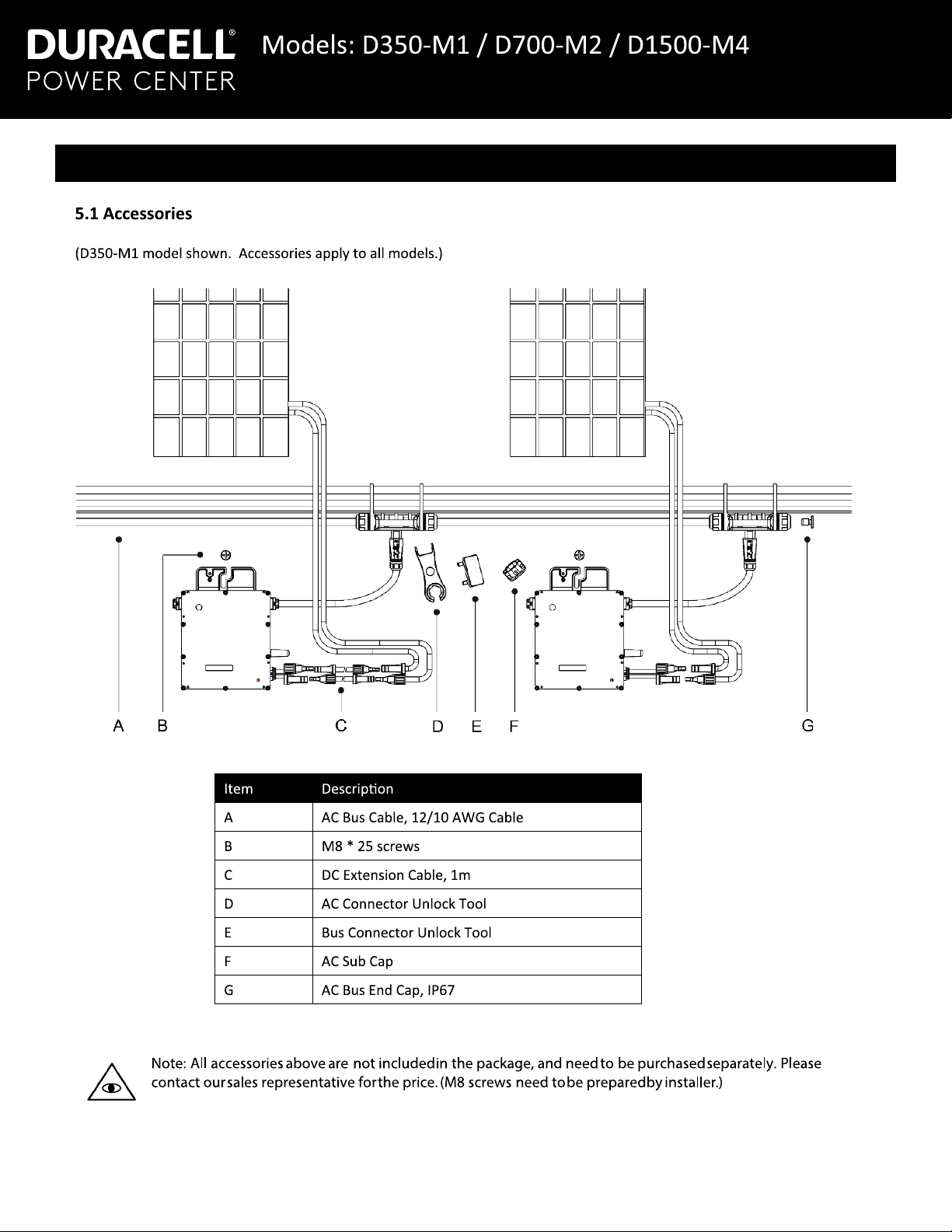

5.1 Accessories ............................................................................................................................................. 5

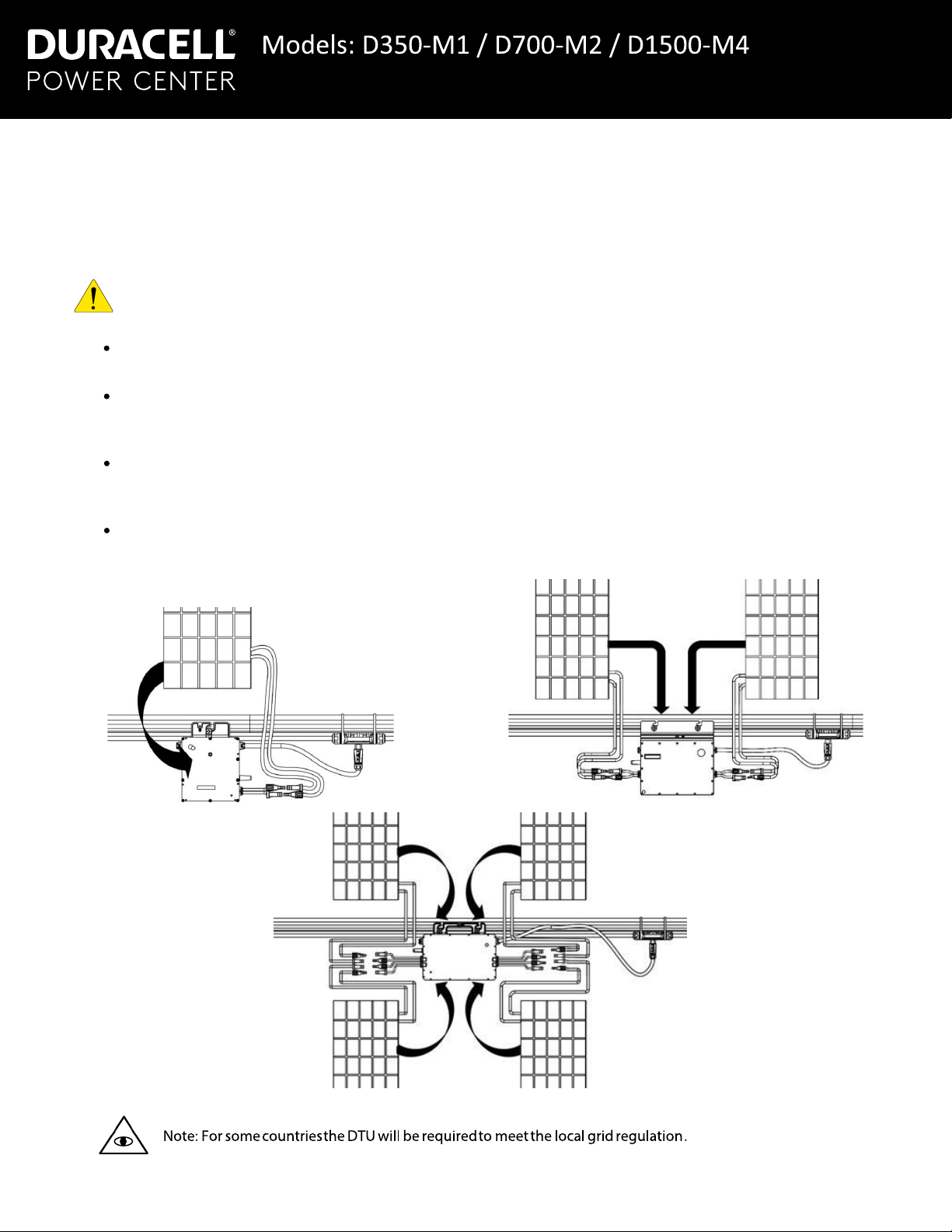

5.2 Installation Precautions............................................................................................................................ 6

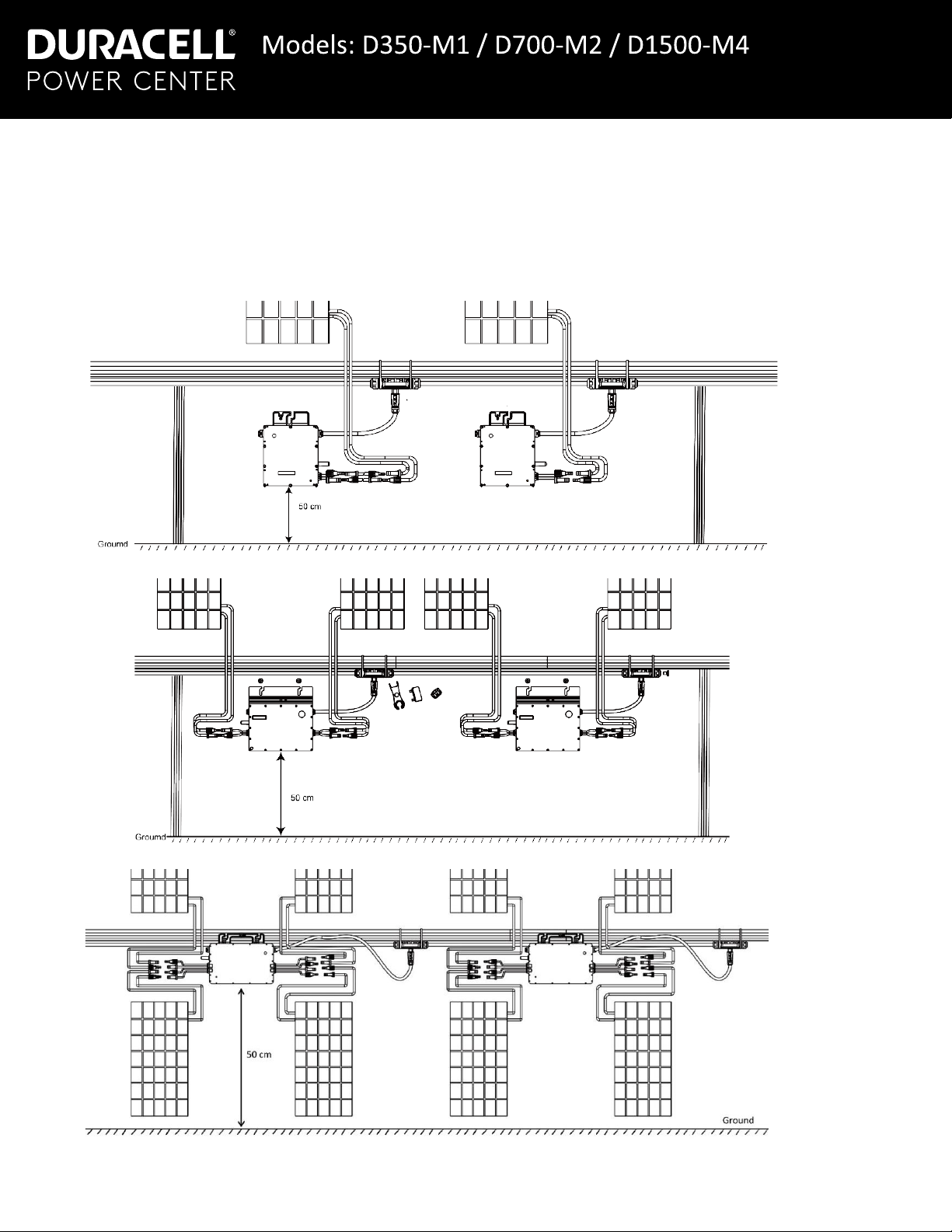

5.3 Space Distance Required ........................................................................................................................ 7

5.4 Preparation .............................................................................................................................................. 8

5.5 Pre-Installation: AC trunk cable end cap installation................................................................................ 8

5.6 Installation: AC trunk cable ...................................................................................................................... 9

5.7 Installation: mounting the microinverter ................................................................................................. 10

5.8 Installation: Connecting the AC trunk cable to the microinverters.......................................................... 10

5.9 Creating an Installation Map .................................................................................................................. 11

5.10 Installation: PV input port connections................................................................................................. 12

6 Energizing the system .................................................................................................................................. 12

6.1 Setting up the monitoring system........................................................................................................... 12

7 Troubleshooting............................................................................................................................................ 13

7.1 Troubleshooting List: all models............................................................................................................. 13

7.2 Troubleshooting List: D350-M1 / D700-M2 ........................................................................................... 13

7.3 Troubleshooting List: D1500-M4 ........................................................................................................... 14

7.4 Status LED Indicator.............................................................................................................................. 15

7.4.1 Start-up Modes ................................................................................................................................... 15

7.4.2 Run Modes ......................................................................................................................................... 15

7.4.3 Other Status ....................................................................................................................................... 15

7.5 On-site Inspection (For qualified installers only) .................................................................................... 15

7.6 Removing a microinverter...................................................................................................................... 16

7.7 Installing the replacement microinverter ................................................................................................ 16

8 Decommissioning ......................................................................................................................................... 16

8.1 Storage and Transportation ................................................................................................................... 16

8.2 Disposal................................................................................................................................................. 17

9 Routine Maintenance.................................................................................................................................... 17

10Technical Data ............................................................................................................................................ 18

11 Grid Support Details ................................................................................................................................... 19

SA9: Low/High Voltage Ride Through (L/H VRT) and Must Trip Settings .................................................... 19

SA10: Low/High Frequency Ride Through (L/H FRT) and Must Trip Settings ............................................. 19

SA11: Ramp Rate (RR) and Soft Start (SS)................................................................................................. 19

SA12: Specified Power Factor (SPF)........................................................................................................... 20

SA13: Volt/VAr (VV)..................................................................................................................................... 20

SA14: Frequency-Watt (FW) ....................................................................................................................... 20

SA15: Volt-Watt (VW) .................................................................................................................................. 20

Appendix A: Installation Map Template ........................................................................................................... 21

Appendix B: 120/240 Split-phase Electrical Single Line Diagram ................................................................... 22

Appendix C: 120/208 Three-phase Electrical Single Line Diagram ................................................................. 23

Appendix D: AC branch limit calculator ........................................................................................................... 24

Installation Manual

Contents

Installation Manual