Page 2 of 47

Table of Contents

Description.............................................................................................................................................................................. 1

Table of Contents.................................................................................................................................................................... 2

Section 3: PSDA-MU1Feature List........................................................................................................................................... 4

Simplified Theory of Managing an IDC Circuit ........................................................................................................................ 5

DuraComm Annunciator Internal Operation Basics ............................................................................................................... 6

DuraComm Annunciator Remote Monitoring Features ......................................................................................................... 6

Section 1 | Important Safety Instructions .............................................................................................................................. 8

Section 2 | Installation............................................................................................................................................................ 8

IMPORTANT SAFETY INSTRUCTIONS............................................................................................................................... 8

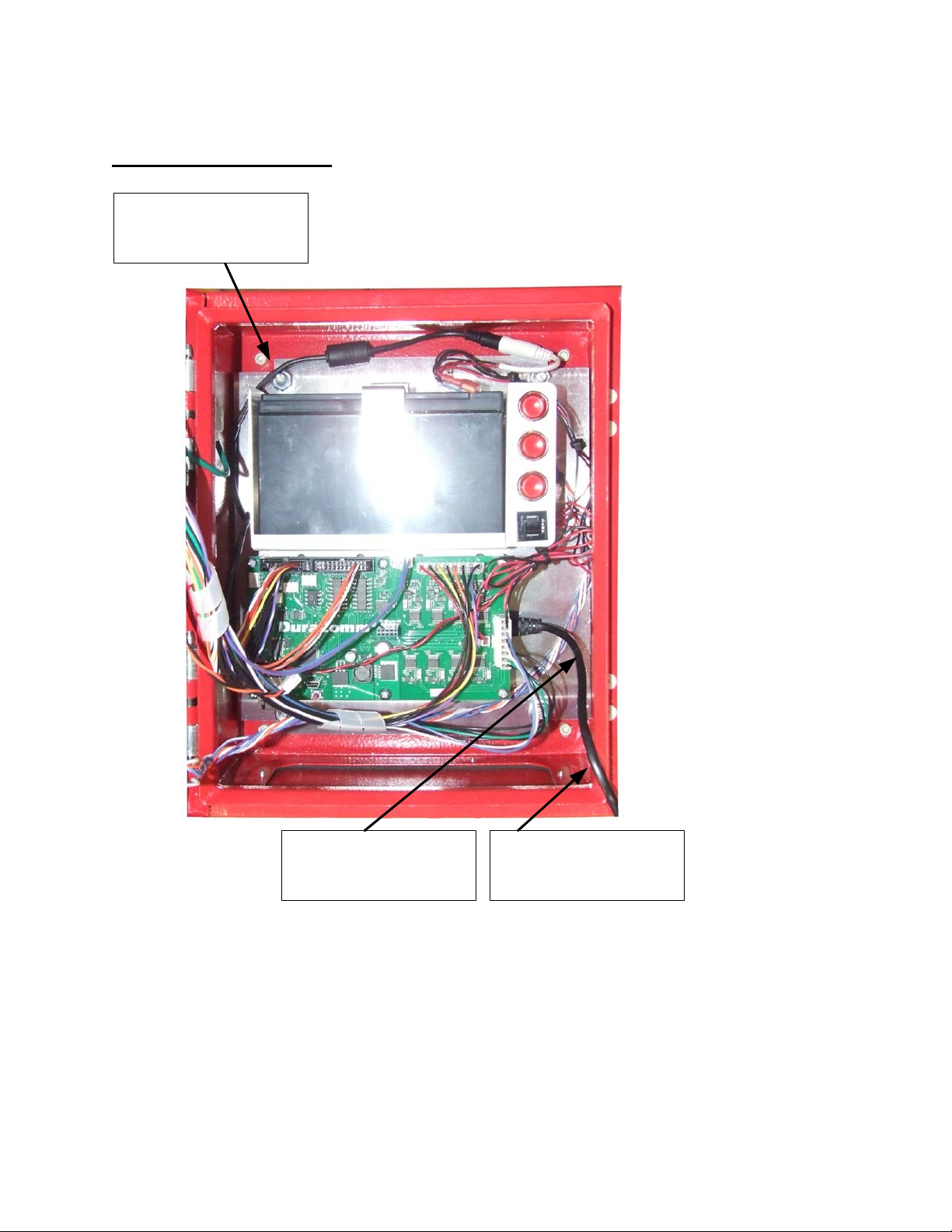

Overall Internal Layout.................................................................................................................................................... 9

Mounting the PSDA-MU1.............................................................................................................................................. 10

AC Power Connection ................................................................................................................................................... 11

RMCU Ethernet Connection.......................................................................................................................................... 11

Supervised Form C Contacts from Equipment.............................................................................................................. 12

Fire Alarm Panel Connections ....................................................................................................................................... 15

Section 3: Self Test................................................................................................................................................................ 16

Section 4: Remote Monitoring Configuration and Operation .............................................................................................. 18

SITEGUARD Description ................................................................................................................................................ 18

Prerequisites ................................................................................................................................................................. 19

Using DHCP ................................................................................................................................................................... 19

Using Static SITEGUARD IP and Network Configuration ............................................................................................... 19

Open a Web Connection to the SITEGUARD................................................................................................................. 20

User Login ..................................................................................................................................................................... 21

Network Setup Notes.................................................................................................................................................... 23

SNMP Traps Setup......................................................................................................................................................... 23

Email Setup Notes......................................................................................................................................................... 24

Device Info .................................................................................................................................................................... 26

Logging .......................................................................................................................................................................... 26

Archive graphing ........................................................................................................................................................... 26

Date and Time Settings ................................................................................................................................................. 26

Miscellaneous Settings.................................................................................................................................................. 26

Sensor Setup (continued – DAC and Scheduling) ......................................................................................................... 28

Sensor Setup Notes....................................................................................................................................................... 29

Alarm Setup Notes ........................................................................................................................................................ 34

Factory Default Alarm Settings ..................................................................................................................................... 35

User Setup – Continued ................................................................................................................................................ 37