12 TALEA™!!!!©2012 Durand Tonearms LLC.All rights reserved!!!!!!!! 13

It is best to leave the screws engaged in the upper arm plate after they are

unscrewed, to avoid losing them. Carefully lift the plate and set it aside (don’t

turn it upside down or on its side, or the little screws will fall off!).

!! Caution !!

The pivot is very sharp. Do not press it hard against the bearing, and avoid contact

with body parts at all times

Lower the armwand onto the pivot. Make sure that the pivot is centered

onto the female part of the bearing (inside the armwand); a few tries might be

necessary to achieve the proper position of the pivot at the bottom of the

bearing. Do not apply any pressure on the bearing.

Make sure that you support the phono cable all the time during this

procedure, until it is securely clamped on the turntable plinth (the cable

is fairly heavy so it will pull strongly on the thin wires). Failure to do this

could result in serious damage to the wires and render the tonearm

useless. Physical damage to the wire is not covered by the warranty.

Check that the thin phono wires are routed properly: they should run inside

the azimuth tower (not under the arm plate), first passing to the side of the

pivot (left or right, as is more convenient for your setup) then exiting to the

back of the arm plate without any hindrance. Attach the clamp of the phono

cable to the turntable plinth with the screw provided in the box. The clamp

should be roughly aligned with the tightening bolt at the back of the VTA

tower.

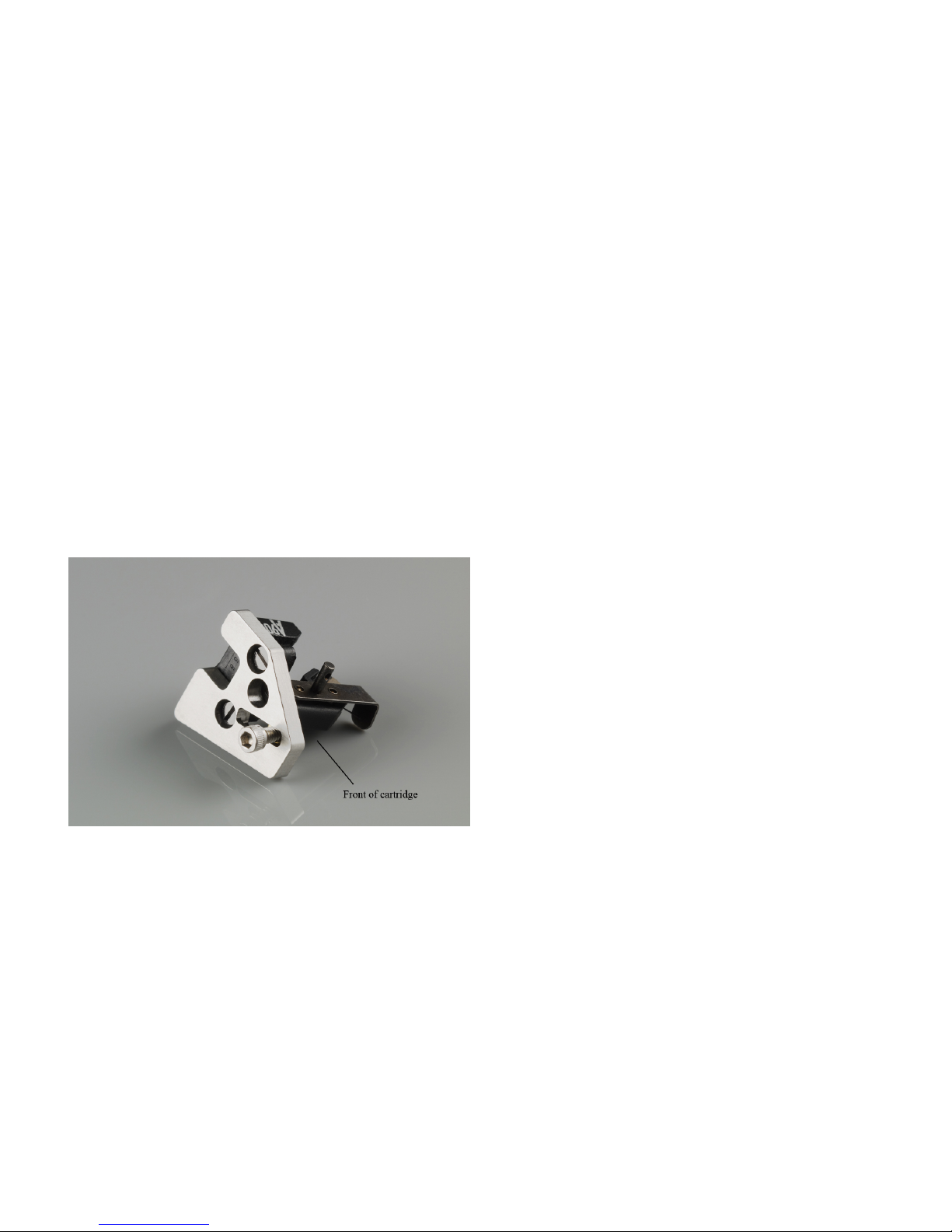

Before placing the upper arm plate back onto the lower arm plate, check the

cartridge position: if the arm is twisted toward the right, as viewed from the

front (cartridge not vertical), you need to insert one of the azimuth weights in

the azimuth bar before proceeding any further. Read carefully the SIDE

COMMENT on the facing page.

Do not change the setting of the azimuth adjustment at this point: since its

range is very limited, you need to first have the cartridge close to vertical so

that you don’t run out of range when you will later adjust the azimuth more

precisely.

Now is the time to install the anti-skating mechanism: see the Side Comment

on the following facing page (P.14).

SIDE COMMENT

The azimuth bar and azimuth weight

You might need to add one of the two azimuth weights

on the azimuth bar in order to balance the tonearm; this

will depend on the weight and shape of your cartridge,

so feel free to experiment with and without weight.The

goal is to make sure that, once the armwand is mounted

and the upper arm plate is in place, the arm is not overly

twisted in one direction of the other and the cartridge

is near vertical. The easiest way to ensure this is to

choose the appropriate azimuth weight before mounting

the upper arm plate back: place the weight on the

azimuth bar so that the cartridge is as vertical as

possible. (see P.23 below, for more information on the

topic on azimuth adjustment). Tighten the set screw on

these weights with the small 1,3-0.05” hex driver.

Note: when setting up the anti-skating mechanism, it is

important to place the azimuth weight on the azimuth

bar before engaging the anti-skating thread. See P.14.