2. SAFETY WARNINGS

WARNING - It is vital for the safety of persons to follow all instructions. Failure to comply with the

following safety rules may result in SERIOUS PERSONAL INJURY and/or PROPERTY DAMAGE.

INSTALLATION

• Wall switch or transmitter must be installed high enough to make sure children can’t reach them.

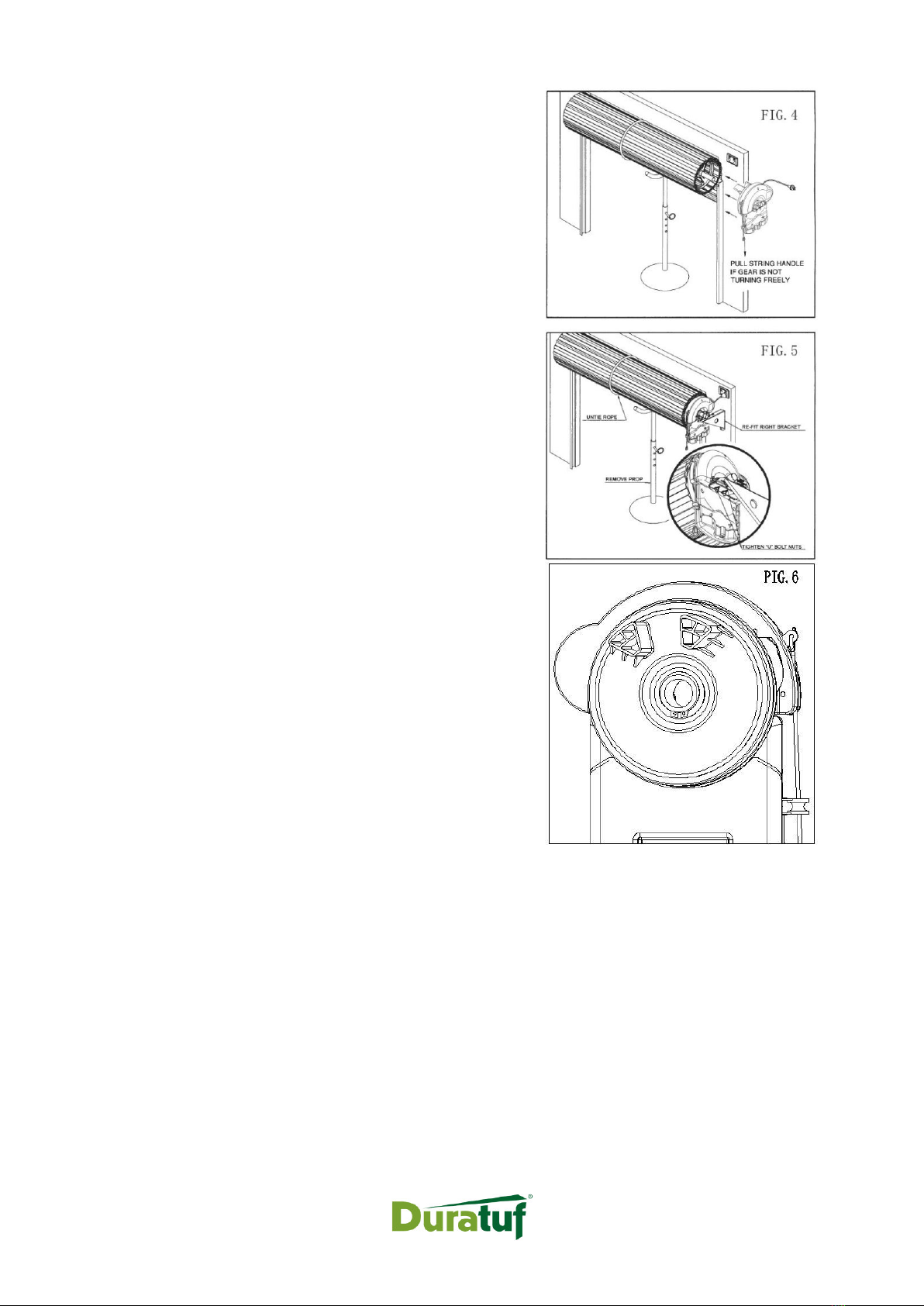

• Remove or disengage all garage door locks and mechanisms prior to installation of the opener.

• The garage door must be well balanced. Sticking or binding doors must be repaired by a qualied garage

door installer prior to installation of the opener.

• Connect the garage door opener to a properly earthed general purpose 240V mains power outlet installed

by a qualied electrical contractor. The outlet (and opener) must be positioned so that it is easily accessible.

• If the roller door is the only entrance to the garage, a back up battery must be installed and checked weekly.

• The unit should be installed so that it is protected from the elements. It should not be exposed to water or

rain. It is not to be immersed in water or sprayed directly by a hose or other water carrying device.

• When using auto close mode, a photo electric beam must be tted correctly and tested for operation at

regular intervals. Extreme caution is recommended when using auto close mode. All safety rules must be

followed.

USAGE

• Make sure that the door is fully open before driving in or out of the garage and fully closed before leaving

the driveway.

• Do not operate the garage door opener unless the garage door is in full view and free from objects such as

cars and people. Make sure that the door has nished moving before entering or leaving the garage.

• Do not allow children to operate the garage door opener.

• Do not disengage the door opener for manual use if people or any other objects including motor vehicles are

within the doorway.

• Keep hands and loose clothing clear of the door and door opener at all times.

MAINTENANCE & REPAIR

• Frequently examine the installation, in particular cables, springs and mountings for signs of wear, damage or

imbalance. Do not use the door if repair or adjustment is needed. Do not attempt to repair the door yourself

as hardware is under extreme tension.

• If the installation is damaged, it must be repaired by a qualied person.

• In order for the garage door opener to sense an object obstructing the door, some force must be exerted on

the object. As a result the object, door and/or person may suffer damage or injury. Regularly check to make

sure that the safety obstruction force is working correctly. Test by placing a 50mm high object on the oor

and set as per the installation instructions manual. Failure to follow the manual could result in serious

personal injury and/or property damage. This test must be repeated at regular intervals and the necessary

adjustments made as required.

• Disconnect the power cord from mains power before making any repairs or removing covers. Only

experienced service people should remove covers from garage door openers.

4