4NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

GENERAL INSTALLATION NOTES

INSTALLATION NOTES

1

1. The chimney is intended for use with solid, liquid,

and gaseous fuel burning appliances. In Canada,

only 6”, 7” and 8” dia. for solid fuel.

Allowable ue gas temperature:

Maximum continuous 1200° F (650°C)

Brief forced ring 1400°F (760°C)

Tested to 2100°F (1150°C) - 30 minutes

2. The maximum height of chimney supported by the

various DuraVent supports are outlined on Table 1.

3. The supports described in this manual should only

be used with DuraVent’s model DTC, 5”, 6”, 7”, 8”

and 10” factory built chimneys.

4. Size the chimney in accordance with the appliance

manufacturer’s instructions.

5. When a restop is required, it is important to follow the

framing dimensions for oor openings as prescribed

in this manual. see Table 2).

6. A chimney servicing a replace or an incinerator shall

not serve any other appliance.

7. The chimney shall extend at least 3 ft above its point

of contact with the roof and at least 2ft higher than

any wall, roof or adjacent building within 10 ft of it.

8. The maximum height of an unguided chimney above

the roof is 5 ft. If the chimney extends more than 5 ft.

above the roof, a Universal Roof Brace (XRB) must

be used.

9. The clearance between single wall pipe and unpro-

tected combustible material must not be less than 18”

(see National Building Code and NFPA 211) except:

The distance between the vertical stove pipe and the

ceiling may be less than 18” and will be established

by the nish support.

10. Multi-Story: Consult local building codes for re-

quirements in your area. In the U.S., the National

Fire Protection Association Standard #211 states:

“Factory-built chimneys that pass through oors of

buildings requiring the protection of vertical openings

shall be enclosed with approved walls having a re

resistance rating of not less than one hour when

such chimneys are located in a building less than

4 stories in height, and not less than 2 hours when

such chimneys are located in a building more than 4

stories in height.” In Canada, except in single-family

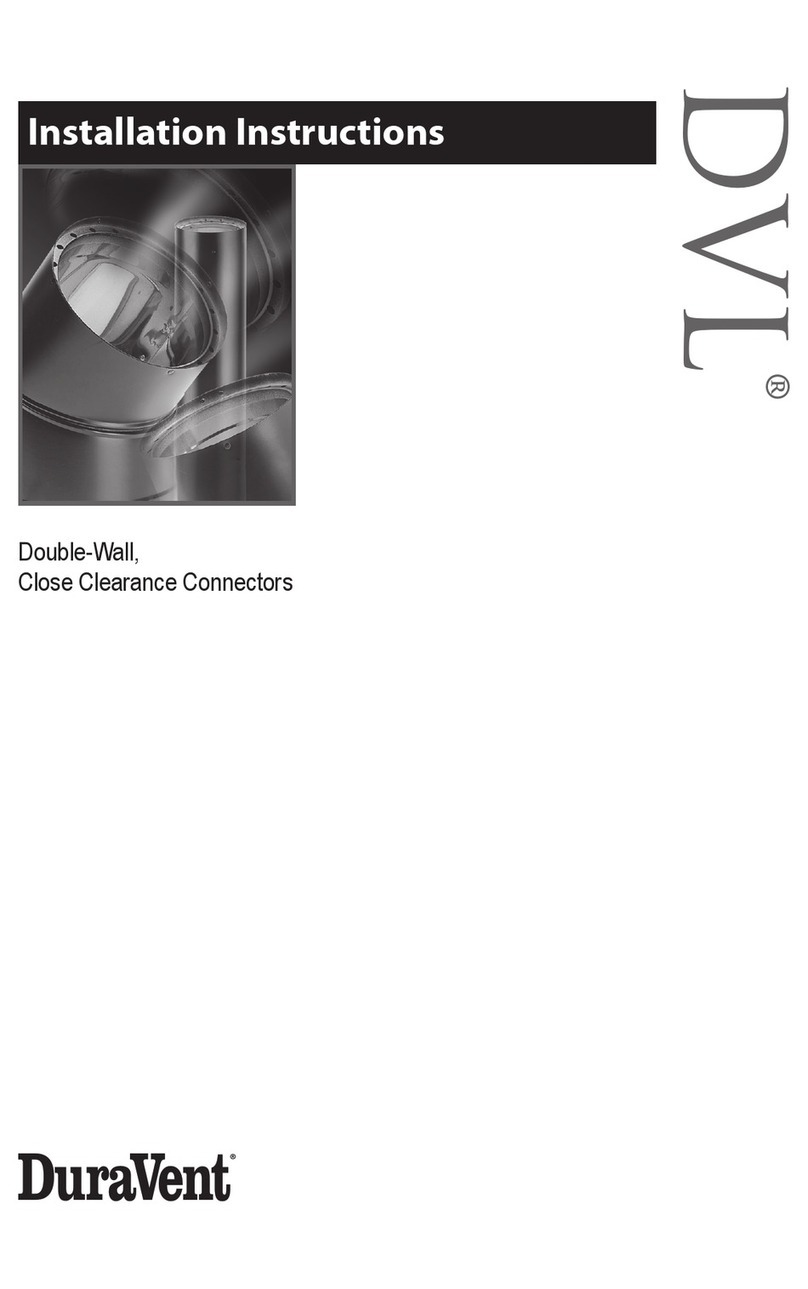

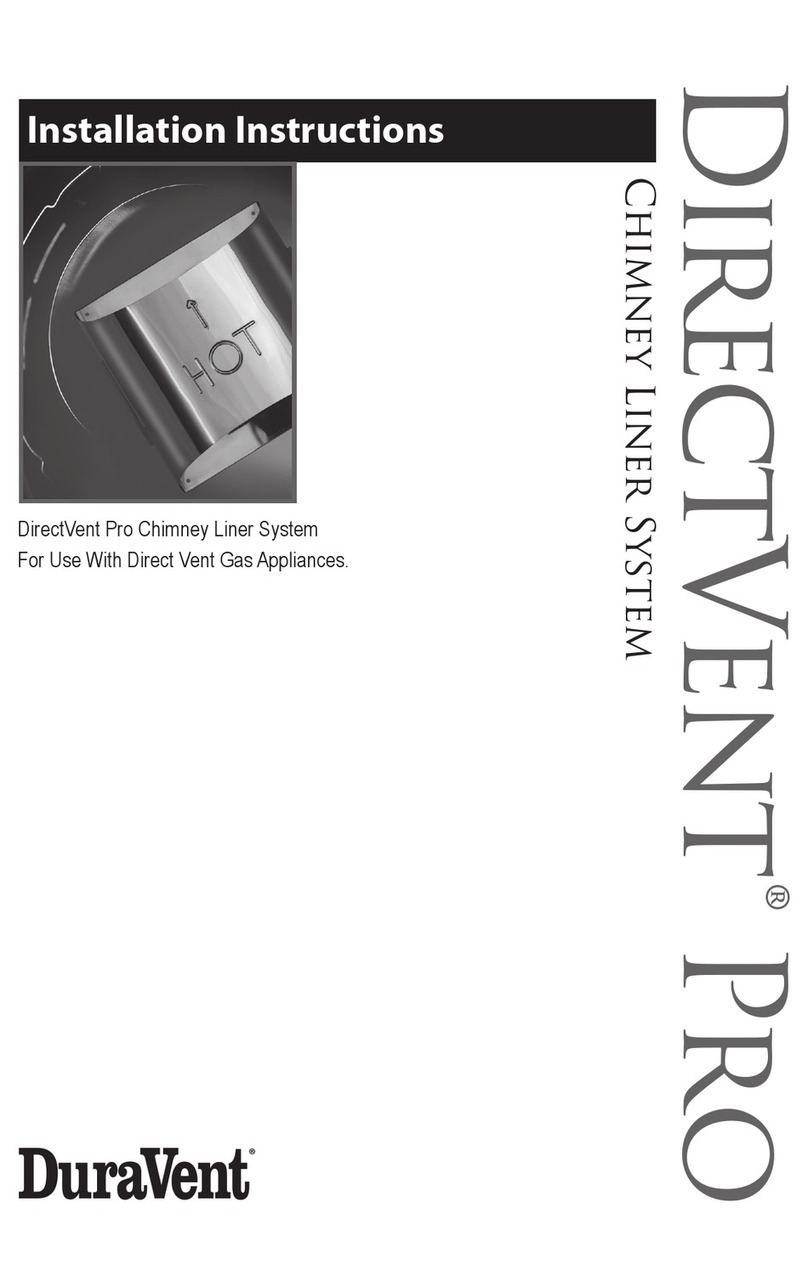

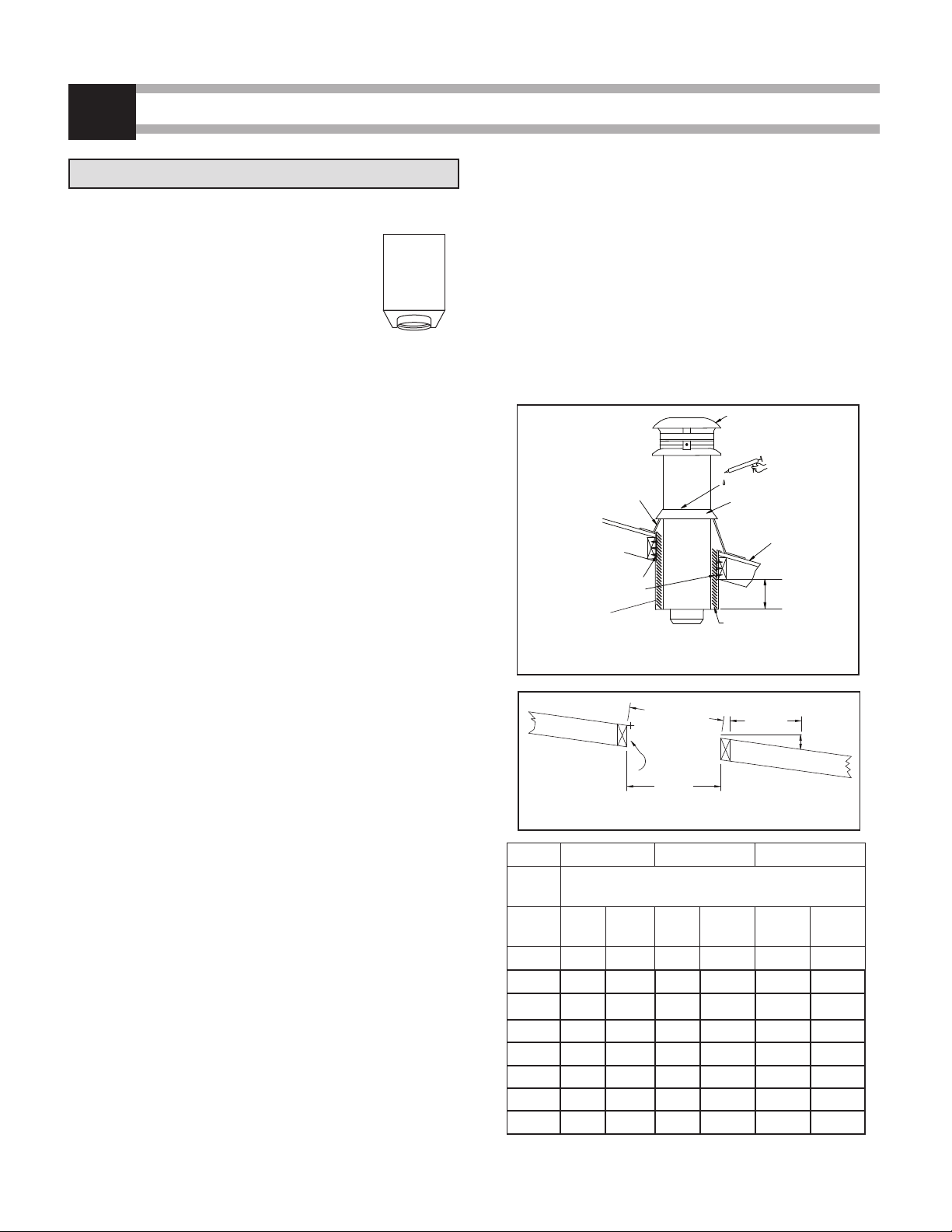

HOLE SIZE

DOWN

B

ROOF SLOPE

INCHES

SIDES OF HOLE

MUST

BE VERTICAL

12 IN

X

ACROSS

SLOPE

A

Figure 1

CHIMNEY SIZE 5” 6” 7”

ROOF SLOPE ROOF HOLE SIZE

x/12 A B A B A B

011-3/8 11-3/8 12-3/8 12-3/8 13-3/8 13-3/8

2/12 11-3/8 11-1/2 12-3/8 12-1/2 13-3/8 13-1/2

4/12 11-3/8 12 12-3/8 13 13-3/8 14-3/32

6/12 11-3/8 12-11/16 12-3/8 13-13/16 13-3/8 14-15/16

8/12 11-3/8 13-11/16 12-3/8 14-7/8 13-3/8 16-1/16

10/12 11-3/8 14-13/16 12-3/8 16-1/8 13-3/8 17-7/16

12/12 11-3/8 16-1/16 12-3/8 17-1/2 13-3/8 18-29/32

ROOF OPENING CHART

CHIMNEY SIZE 8” 10”

ROOF SLOPE ROOF HOLE SIZE

x/12 A B A B

014-3/8 14-3/8 16-3/8 16-3/8

2/12 14-3/8 14-9/16 16-3/8 16-19/32

4/12 14-3/8 15-5/32 16-3/8 17-1/4

6/12 14-3/8 16-3/32 16-3/8 18-5/16

8/12 14-3/8 17-1/4 16-3/8 19-11/16

10/12 14-3/8 18-23/32 16-3/8 21-5/16

12/12 14-3/8 20-11/32 16-3/8 23-5/32

Table 2 - Refer to Figure 1