3

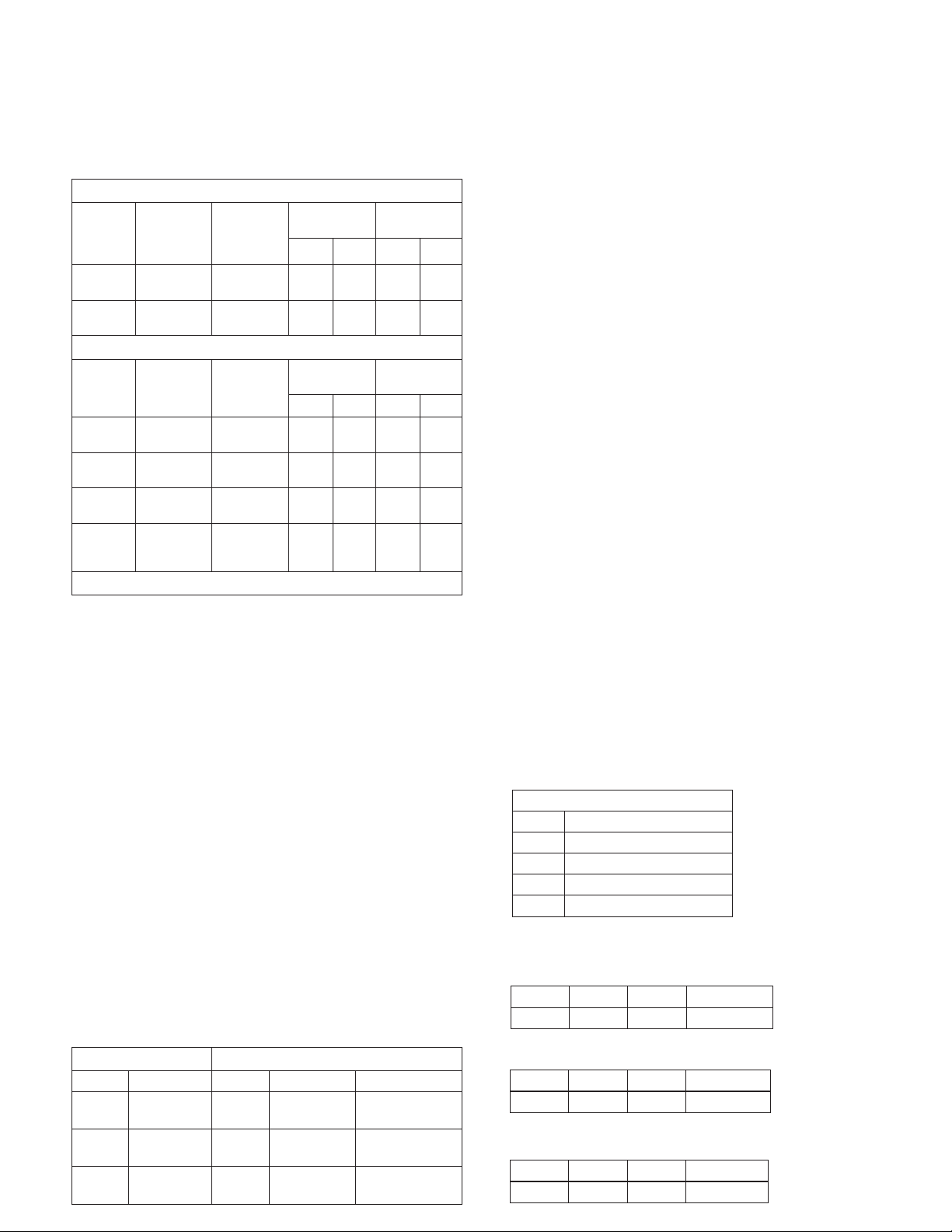

CLEARANCES TO COMBUSTIBLES

Table 1 shows the required MINIMUM AIRSPACE CLEARANCE TO COMBUS

-

TIBLES. “Combustibles” include framing lumber, drywall, plywood, paneling,

insulation, wiring and other building materials.

Minimum Clearance to Combustibles Single Wall DS

Diameter

Rated

operating

temperature

Max.

operating

temperature

Enclosed

(4 sides)

Unenclosed

(2 sides Max.)

Horiz. Vert. Horiz. Vert.

3” to 12” 480º F

(250º C)

550º F

(288º C) N/A N/A 2” 2”

14” to 24” 480º F

(250º C)

550º F

(288º C) N/A N/A 4” 4”

Minimum Clearance to Combustibles Double Wall DSD / DSID

Diameter

Rated

operating

temperature

Max.

operating

temperature

Enclosed

(4 sides)

Unenclosed

(2 sides Max.)

Horiz. Vert. Horiz. Vert.

3” to 12” 480º F

(250º C)

550º F

(288º C) N/A 1” 1” 1”

14” to 24” 480º F

(250º C)

550º F

(288º C) N/A 1” 3” 1”

3” to 12”

L-VENT

480º F

(250º C)

550º F

(288º C) N/A 2” 2” 2”

14” to

24”

L-VENT

480º F

(250º C)

550º F

(288º C) N/A 2” 3” 2”

Table 1 - Minimum Clearances for DuraSeal®

Auxiliary parts such as combination Roof Supports, Roof Thimble, Flashings

and Wall Thimble outer shields are intended to be attached directly to the

framing or to ceilings, floors, or walls in accordance with their respective

instructions. These parts, which are installed in contact with wood or other

combustibles, are designed and tested to assure that they do not overheat

at points of contact.

Notes:

1. Unenclosed requires at least two sides open.

2. Single Wall (DS) may be enclosed only in non-combustible enclosure.

3. Reduced clearances maybe attained by using non-combustible enclosures.

4. Combustible Material is any material made of or surfaced with wood,

compressed paper, plant fibers or other materials that are capable of being

ignited or burned. Such material shall be considered combustible even

though it is flame-proofed, fire-retardant treated, or plastered. (Source:

NFPA 54/ANSI Z223.1)

5. Design any enclosure to permit inspection of the system.

6. Do not place insulation in any required clearance spaces surrounding the

vent system unless these instructions suggest otherwise and the insulation

is specified or supplied.

7. When using Viton caulking, follow the manufactures required drying times.

GENERAL INSTALLATION REQUIREMENTS

When venting Category I, II, III, or IV appliances or TYPE L vented appliance,

DuraSeal must be used for the entire length of the system. Do not mix pipe,

fittings, or joining methods from different manufacturers. See the DuraSeal

catalog for a complete list of parts and products. Every vent system

must be planned and installed for optimum performance and safety. The

venting system must be free to expand and contract and must be supported

in accordance with these instructions. (Check for unrestricted vent movement

through walls, ceilings, and roof penetrations). Refer to the gas appliance

manufacturer’s instructions to determine venting requirements and limitations

with respect to installation and use of the appliance. It is the responsibility

of the installer to contact local building and fire officials concerning

any installation restrictions and/or inspection requirements that may

apply. Permits may be required before starting an installation.

• If required by the appliance manufacturer, a Drain Tee Cap must be

located as close as possible to the appliance flue outlet. Depending on

the arrangement of the vent, more than one drain may be required.

Unless a Drain Tee Cap is supplied with the appliance, install a DuraSeal

Drain Tee Cap.

• More than one Category II, III or IV appliance may not be connected into

the same vent system, unless the appliance manufacturer specifically

approved such a system and the appliance are designed for multiple

venting. Cat. II, III or IV appliances MAY NOT be common vented with Cat.

I, natural draft appliances. This limitation can be removed if an engineering

analysis demonstrates normal and safe operation of appliances.

• DuraSeal must not come in contact with plumbing or electrical systems.

• Maintain rated clearances to combustibles over the entire length of the

vent system.

• DuraSeal shall not be routed into, through, or within any vent, such as an

existing masonry or factory-built chimney, that is connected to another

appliance.

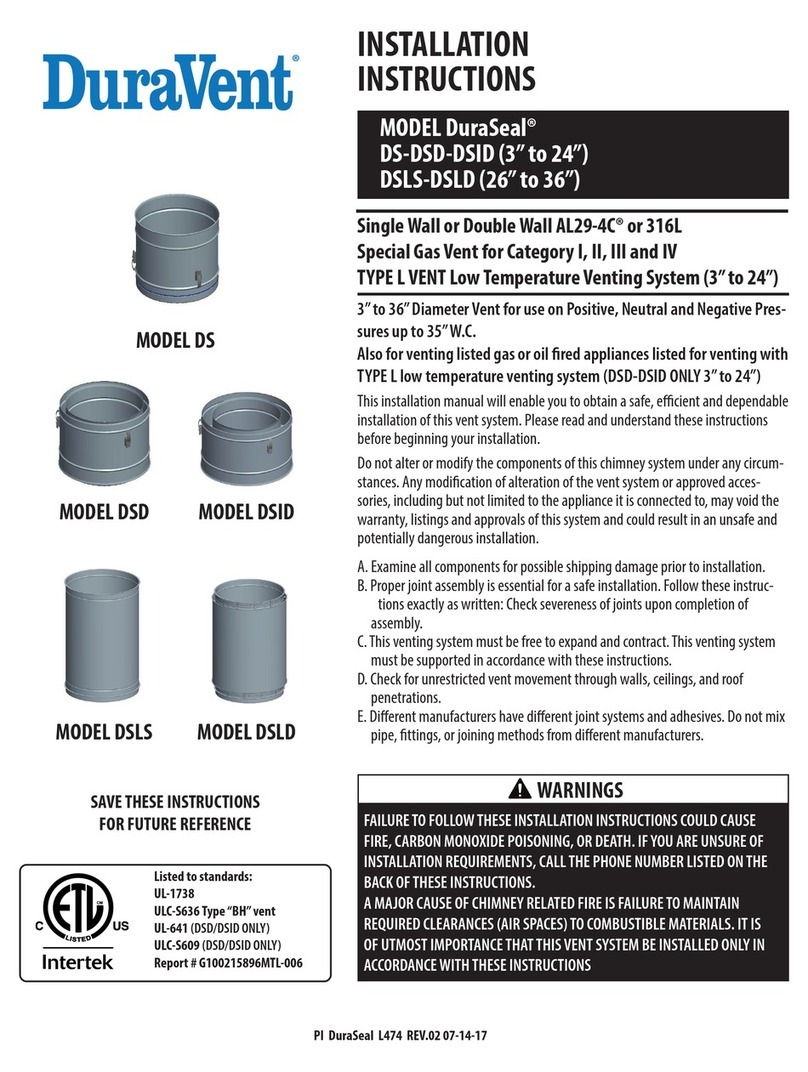

Material Thickness

*all seams are laser welded

DuraSeal DS DuraSeal DSD / DSID

Diameter Flue Diameter Flue Casing

3” to 9” AL29-4C - .015”

316L - .015” 3” to 9” AL29-4C - .015”

316L - .015” 441 stainless - .015”

10” to 16” AL29-4C - .020”

316L - .019” 10” to 16” AL29-4C - .020”

316L - .019” 441 stainless - .020”

18” to 24” AL29-4C - .024”

316L - .024” 18” to 24” AL29-4C - .024”

316L - .024” 441 stainless - .024”

Material Code Designations

B Type 316 Stainless Steel

H Type 430 Stainless Steel

K Type 441 Stainless Steel

P Type 439 Stainless Steel

U Type AL29-4C Stainless Steel

PART NUMBERS

These instructions identify major model DS-DSD-DSID parts by name and part number.

Example:

DSD 36” length with inside diameter 14” made of AL29-4C inner flue and

SS441 outer casting.

DS 30° elbow with inside diameter 22” made of 316L.

DSD wall support for 8” diameter chimney made of stainless 439.

DSD 14 L36 UK

Model Dia. Part Material

DS 22 E30 B

Model Dia. Part Material

DSD 8 WSHD P

Model Dia. Part Material