4

LISTING

Listed to ULC S636

Rated Class IIA, IIB, and IIC vent system

maximum temperature 230°F (110 °C)

maximum positive pressure 15 in-w.c.

Massachusetts Plumbers Board,

# G1-0811-42

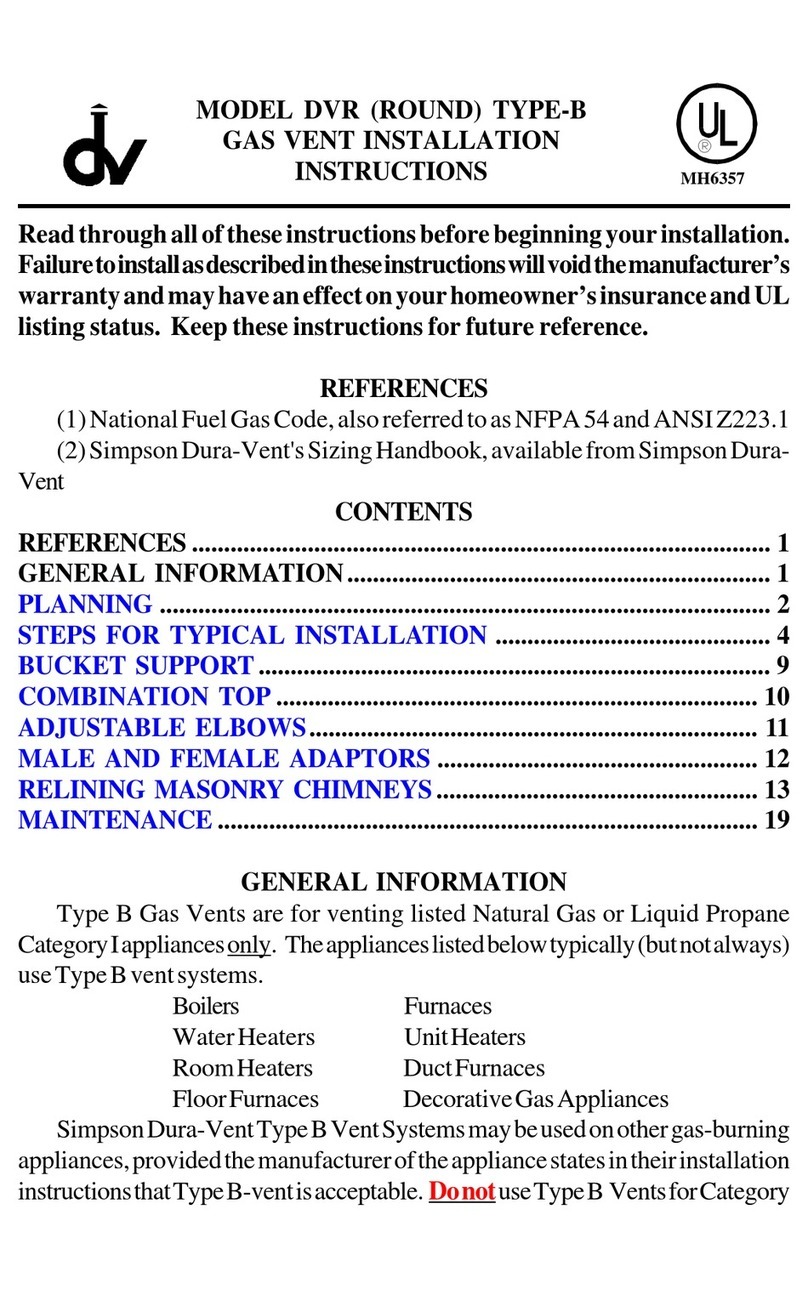

APPLICATION

ANSI Category II and IV gas-burning

appliances with a maximum positive

pressure of 15in w.c. and maximum ue gas

temperature of 230°F (110°C, ULC-S636-Class

IIC).

Appliances specically tested and listed to

use DuraVent PolyPro Venting.

PERMITS

Check with your local Building Ocial, Fire

Ocial, or other authority having jurisdiction

(AHJ) regarding permits, restrictions, and

installation inspections in your area.

GENERAL INSTALLATION NOTES

Read these instructions before beginning.

You must use only authorized DuraVent

PolyPro vent parts, or other parts specically

authorized in these instructions and/or listed

by the appliance manufacturer in order to

maintain a safe, approved system.

• Do not mix parts or try to match with

other products or use improvised

solutions.

• Do not install damaged or modied

parts.

• Use soapy water to lubricate gaskets.

• Never use petroleum base lubricants.

If these directions and those of the appliance

manufacturer dier, follow the more

conservative requirements. If you have any

questions, contact either your dealer or

DuraVent directly. A venting system must

not be routed into, through, or within any

other vent, such as an existing masonry or

factory-built chimney ue, unless that vent

or chimney is not being used to vent another

appliance and is only used as a conduit for

the gas-vent system. Plastic venting systems

shall not pass through re rated separations

without approved restopping.

PolyPro Single-Wall attains Flame Spread /

Smoke Developed ratings of <25 / <50 (per

UL-723, ASTM E-84 and ULC-S102) when

used in conjunction with the below noted

materials:

• 3M Fire Barrier Plenum Wrap 5A+

• Unifrax FyreWrap 0.5 Plenum Insulation

• Knauf Insulation- Atmosphere Duct

Wrap with ECOSE

• Alternate equivalent listed product

Always follow the particular installation

instructions from the insulation wrap

manufacturer, in addition to those for the

PolyPro vent system. The venting system

shall be securely supported using suitable

hangers installed after the pipe has been

properly wrapped. Hardware must not

deform or damage the vent or wrap.

Table 1

Clearance to Combustibles

VENT PIPE ORIENTATION

Single Wall Vertical Horizontal

Up to 190°F 0" 0"

Up to 230°F 0" ¼" (6mm) all around

Concentric

Up to 230°F 0" 0"

The vent system must be compliant in

accordance with local code requirements

and appropriate National Codes: In

the US: NFPA 54 / ANSI Z223.1 National

Fuel Gas Code or the International Fuel

Gas Code. In Canada: CAN/CGA-B149.1

Natural Gas Installation Code or CAN/CGA-

149.2 Propane Installation Code.

IMPORTANT