DuraVent DVR User manual

Other DuraVent Fan manuals

DuraVent

DuraVent DURATECH PREMIUM User manual

DuraVent

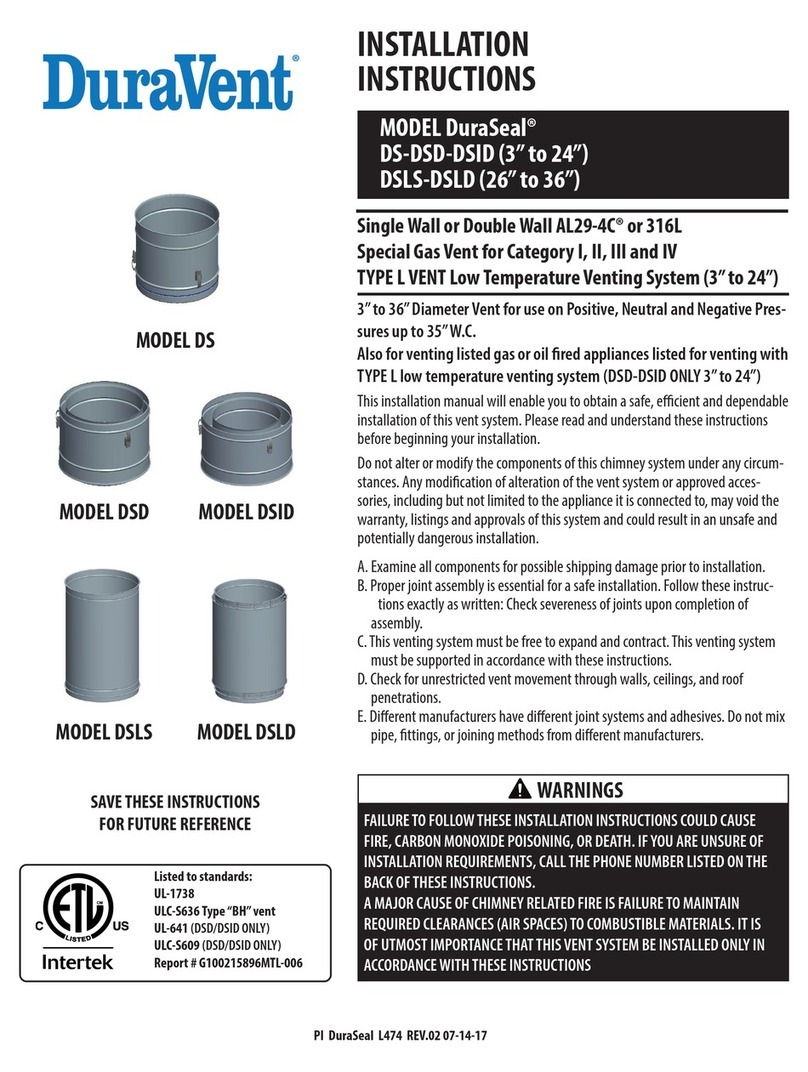

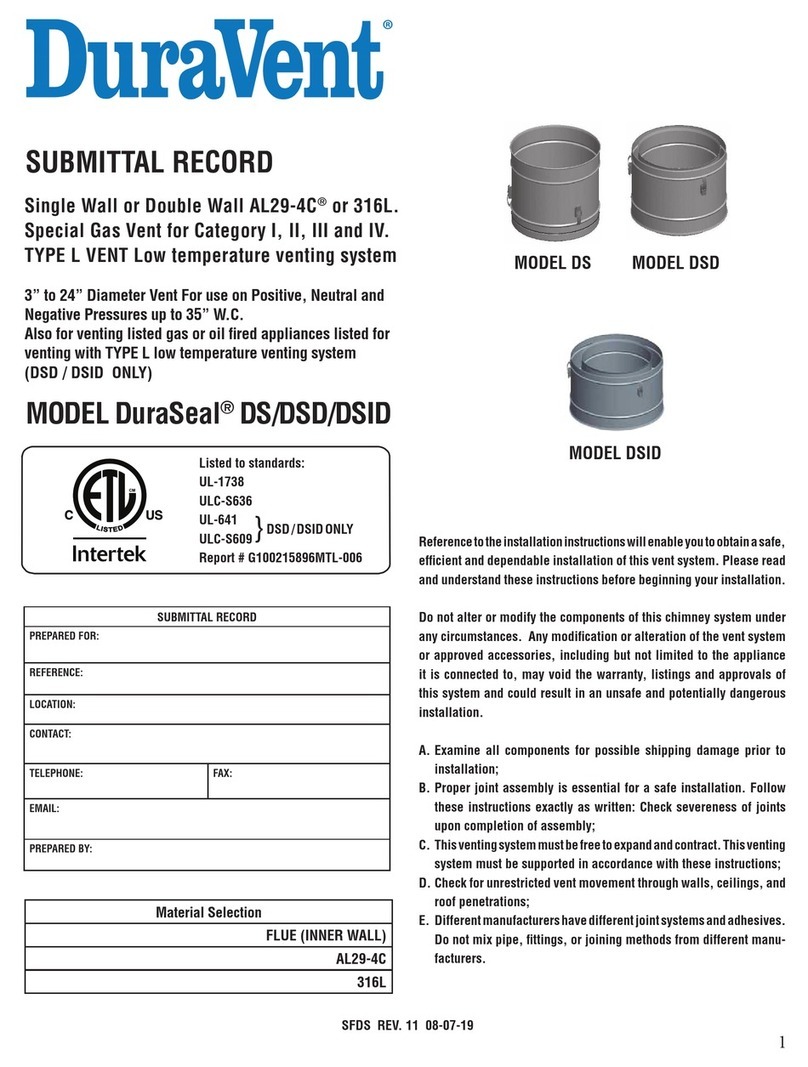

DuraVent DuraSeal DS User manual

DuraVent

DuraVent DDW Double-Wall User manual

DuraVent

DuraVent polypro User manual

DuraVent

DuraVent BV User manual

DuraVent

DuraVent PelletVent UL 641 User manual

DuraVent

DuraVent duraplus htc User manual

DuraVent

DuraVent duraplus htc User manual

DuraVent

DuraVent DVL User manual

DuraVent

DuraVent PolyPro Flex Series User manual

DuraVent

DuraVent DuraTech Canada User manual

DuraVent

DuraVent DuraSeal DS User manual

DuraVent

DuraVent DirectVent Pro User manual

DuraVent

DuraVent DirectVent Pro User manual

DuraVent

DuraVent duraplus User manual

DuraVent

DuraVent PolyPro Series User manual

DuraVent

DuraVent DIRECT-TEMP Co-Linear Insert Kit User manual

Popular Fan manuals by other brands

ELTA FANS

ELTA FANS H03VV-F installation guide

Hunter

Hunter 20714 Owner's guide and installation manual

Emerson

Emerson CARRERA VERANDA CF542ORB00 owner's manual

Hunter

Hunter Caraway Owner's guide and installation manual

Panasonic

Panasonic FV-15NLFS1 Service manual

Kompernass

Kompernass KH 1150 operating instructions