NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

5

Type B Gas Vent

for Category II, III

or IV gas appli-

ances, or for any

gas appliance

which requires

either a pres-

sure-tight or liq-

uid-tight venting

system.

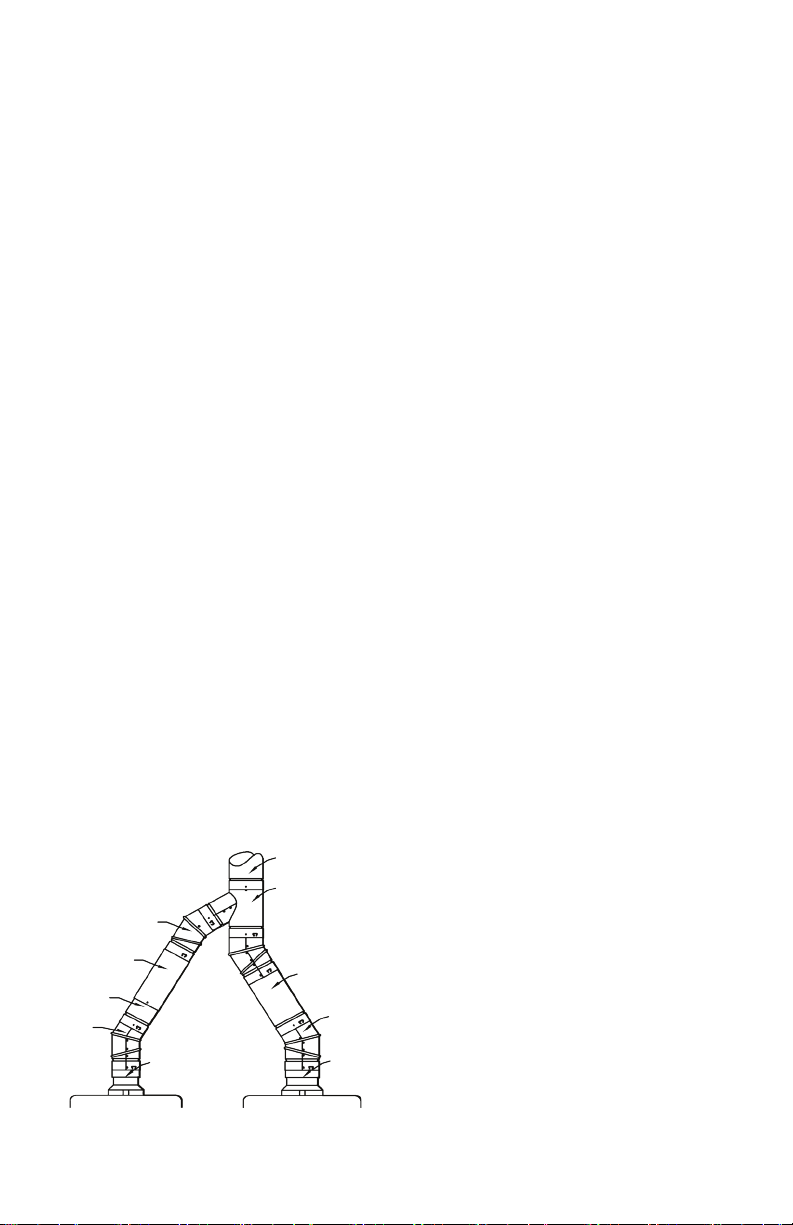

All sizes of Model BV Type B Gas Vent may

be used in single and multistory buildings. All

Model BV Type B Gas Vents may be used for

both individual and multiple appliance venting.

Model BV Type B Gas Vents are to be installed

and used in accordance with the “National

Fuel Gas Code”, NFPA 54, the “Standard for

Chimneys, Fireplace and Venting Systems”,

NFPA 211, the “International Fuel Gas Code”.

In Canada, Model BV Type B Gas Vents are

to be installed and used in accordance with

the “Canadian Fuel Gas Installation Code”,

CSA-B149.1-00, and/or applicable local/

regional codes. Model BV Type B Gas Vent

is also suitable for use in existing, otherwised

unused and new masonry chimneys to protect

the chimney from damaging eects of moist

combustion products from the appliances listed

above. NEVER USE Model BV Type B Gas

Vent on any appliance that is not listed and

approved for venting with Type B Gas Vent.

Model BV Type B Gas Vent is designed for

venting listed Natural Gas or Liquid Propane

Category I gas appliances equipped with draft

hoods and other listed gas appliances spec-

ied for use with Type B gas vent producing

ue gas temperatures not in excess of 470°F

(245°C). These appliances include (but are

not limited to) the following types: furnaces,

boilers, water heaters, room heaters, unit

heaters, duct furnaces, oor furnaces, and

decorative appliances.

DO NOT USE Model BV Type B Gas Vent for

wall furnaces “Listed” for use with Type BW

Gas Vents only, incinerators and appliances

Listed for use with chimneys only, combination

gas-oil burning appliances, and appliances

which may be converted readily to the use of

solid or liquid fuels. DO NOT USE Model BV

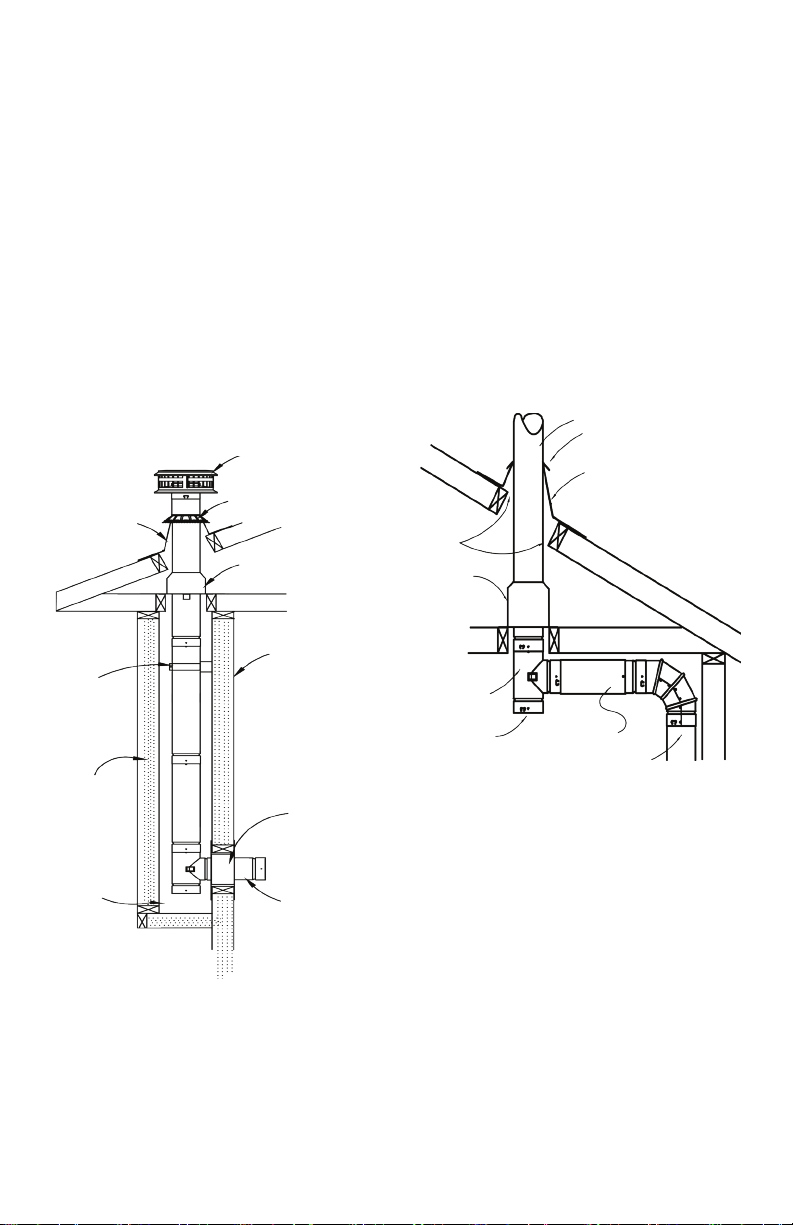

3. GAS VENT JOINT METHOD

All joints of Model BV Type B Gas Vent

must be secured using the “DuraLock”

feature. To use the DuraLock feature, ori-

ent sections as shown in Fig.1 and push

adjacent pieces together until fully engaged.

NOTE: Some local jurisdictions require a sup-

plemental screw(s) at joints to prevent disen-

gagement of the joint. Although not required

under the terms of the UL Listing because of

the integral couplers, screws are permitted to

be installed at the joints in 3” through 8” vent.

In such case, the screws should be located

aproximately 1/4” from overlapped edge and

must be maximum 1/4” in length so they do not

pierce or deform the inner liner.

The DuraTab® feature provides the equivalent

of using a screw. Once engaged (with nger or

Failure to follow the installation

instructions could cause FIRE,

CARBON MONOXIDE POISONING, OR

DEATH. If you are unsure of installation

requirements, call the Phone Number

listed on the instructions, 1-800-835-4429

or visit www.duravent.com.

WARNING

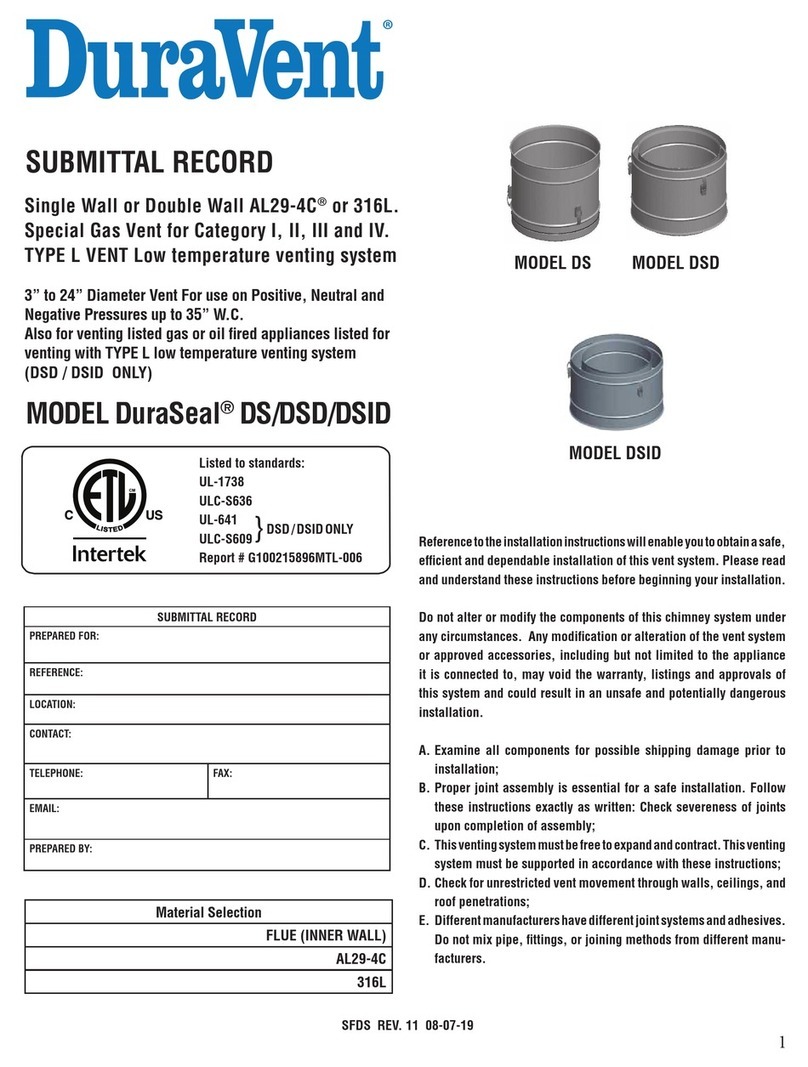

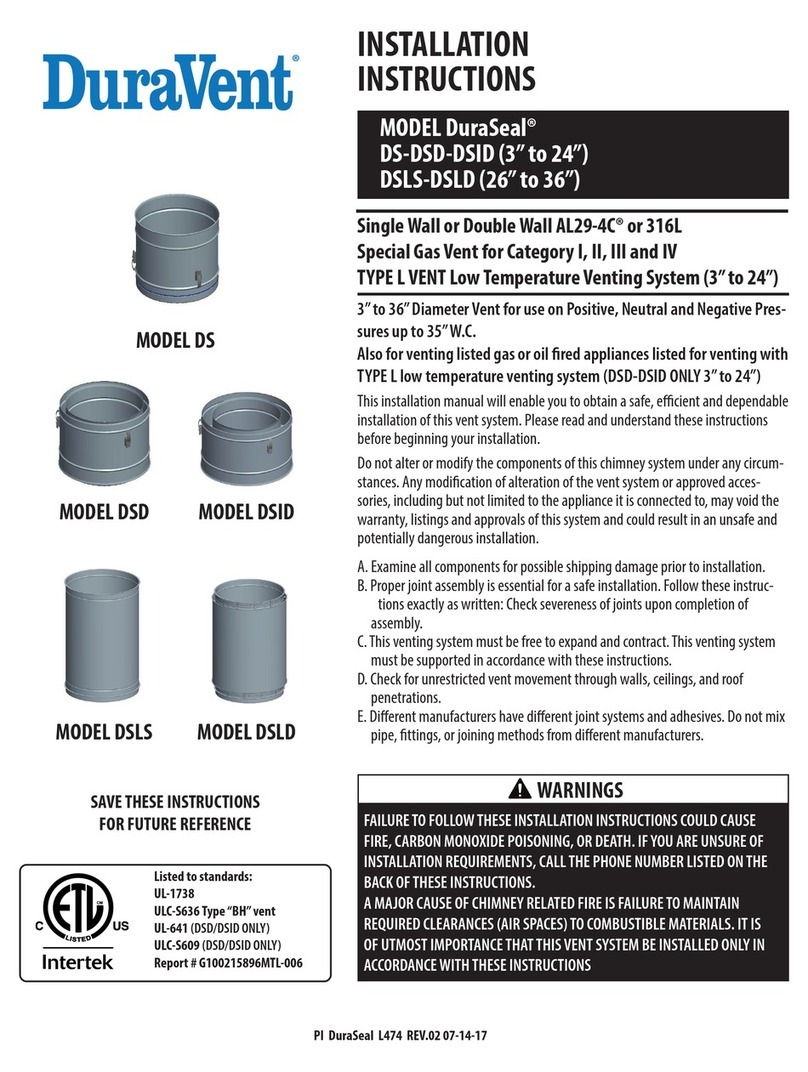

1. GAS VENT DESIGNATIONS/

TYPES OF APPLIANCES

DuraVent Model BV Type B Gas

Vent parts LISTED and produced under the

Factory Inspection and Follow-up program

of Underwriters’ Laboratories, Inc. carry the

LISTING MARK illustrated here. Type B Gas

Vent has been tested, and listed using all of

the supports, restop, etc., described herein.

Deletion or modication of any of the required

parts or materials may seriously impair the

safety of your installation, and void the certi-

cation and or warranty of this vent. It is of the

utmost importance that this vent be installed

only in accordance with these instructions.

Model BV Round is listed to UL 441 and CAN/

ULC-S605 in diameters of 3” to 30”. Model

BVO Oval is listed to UL 441 in diameters of

4” to 6”. Model BVO Oval is not available in

Canada.

CAUTION: WEAR GLOVES WHILE

HANDLING METAL PARTS TO AVOID

PERSONAL INJURY. SHARP EDGES OR

PROJECTIONS CAN CUT YOU.

2. TYPES OF APPLIANCES AND BUILDINGS

SECTION 1

FIG. 1 - 3” to 8” BV