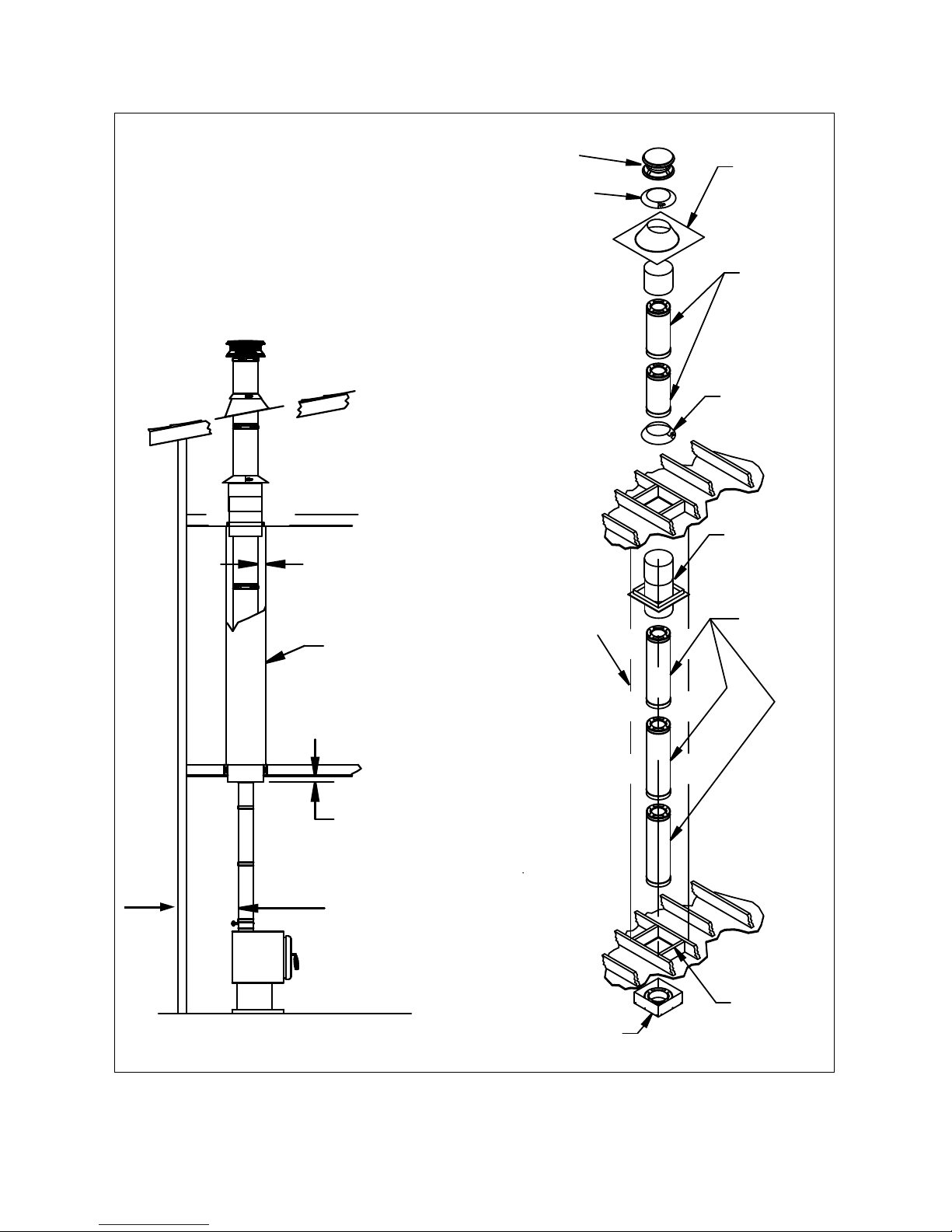

Review the step-by-step directions before

beginning your installation.

CEILING SUPPORTED

1. Place Appliance: Position the appliance

according to the manufacturer’s instructions.

The ue outlet collar should be placed

between the rafters or joists above,

if possible.

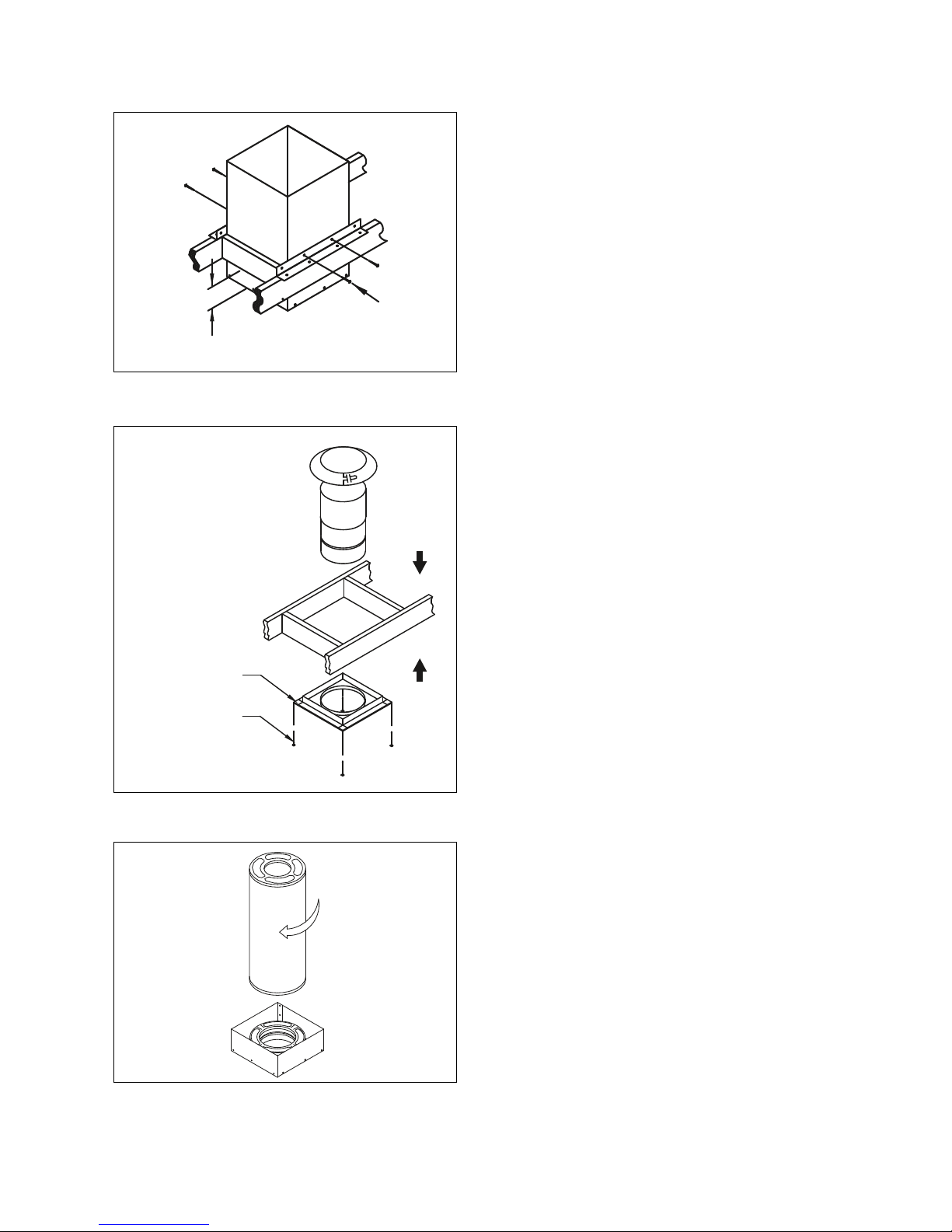

2. Frame Support Opening: Use a laser

level or drop a plumb bob to the center of

the appliance’s ue outlet and mark this

center point on the ceiling. Refer to Table 2

for framing dimensions. Mark a cutting line

around the center point to the dimension

required in Table 2. Cut a square hole in the

ceiling for the Support Box. Frame a level,

square opening centered over the hole which

you have cut. (Figures 3 and 4).

3. Install Support: For installation into a

at ceiling, you may use a Square Ceiling

Support Box, a Round Ceiling Support Box, a

Reduced Clearance Support Box, or the CAS

Ceiling Support. Note: each of the Ceiling

Supports act as a restop at the ceiling level;

an additional restop is not needed at that

level. Each Ceiling Support can support a

maximum of 40-feet (12.2 m) of chimney.

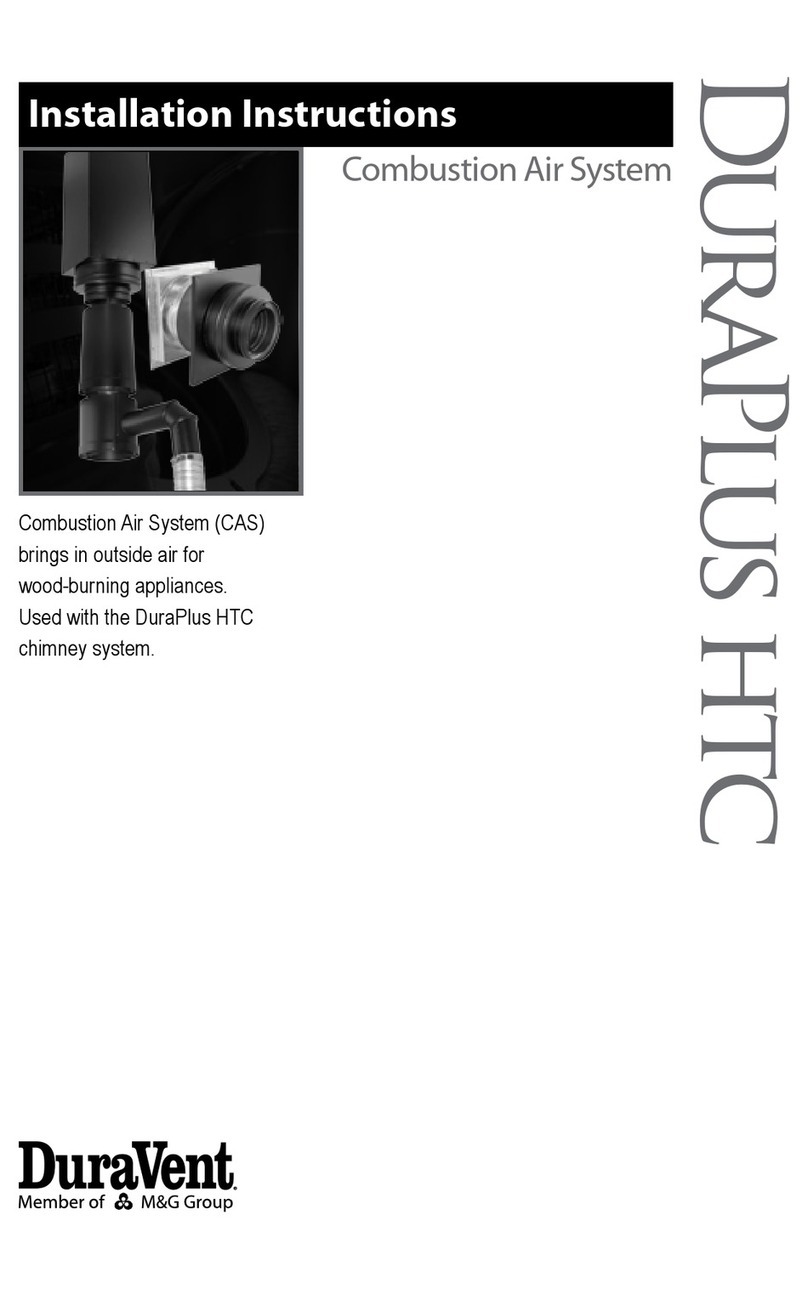

The CAS Ceiling Support is only used when

installing the CAS system. Refer to the

DuraPlus HTC CAS Installation Instructions for

directions on how to install the remainder of

the Combustion Air System. For the Square

Ceiling Support Box, refer to the cathedral

ceiling installation below. The bottom of the

Round Ceiling Support must extend at least

3 inches (75 mm) below the nished ceiling.

Level the Ceiling Support and secure it to the

framing using at least three 8-penny nails per

side (min. of 12 total). Alternatively, you may

use 1-1/2” #8 wood screws (min. of 12 total),

instead of nails. Next, secure the two-piece

Trim Collar to the framing members using

the (6) 1-1/4” long, round-head wood screws

provided (Fig 6).

For installation into a cathedral ceiling, you

must use the Square Ceiling Support Box,

Reduced Clearance Support Box, or the CAS

Ceiling Support and the two-piece Trim. The

bottom of the square portion of the Support

Box must be a minimum of 3 inches (75 mm)

lower than the nished ceiling at the lowest

side of the penetration (Fig 5 & 6). Level the

Support Box . Support Box Guide Rails are

available for Cathedral Ceiling Support Boxes

to help ensure the Support Box is level during

installation. Before installing the Support Box,

align the Guide Rails level onto the Support

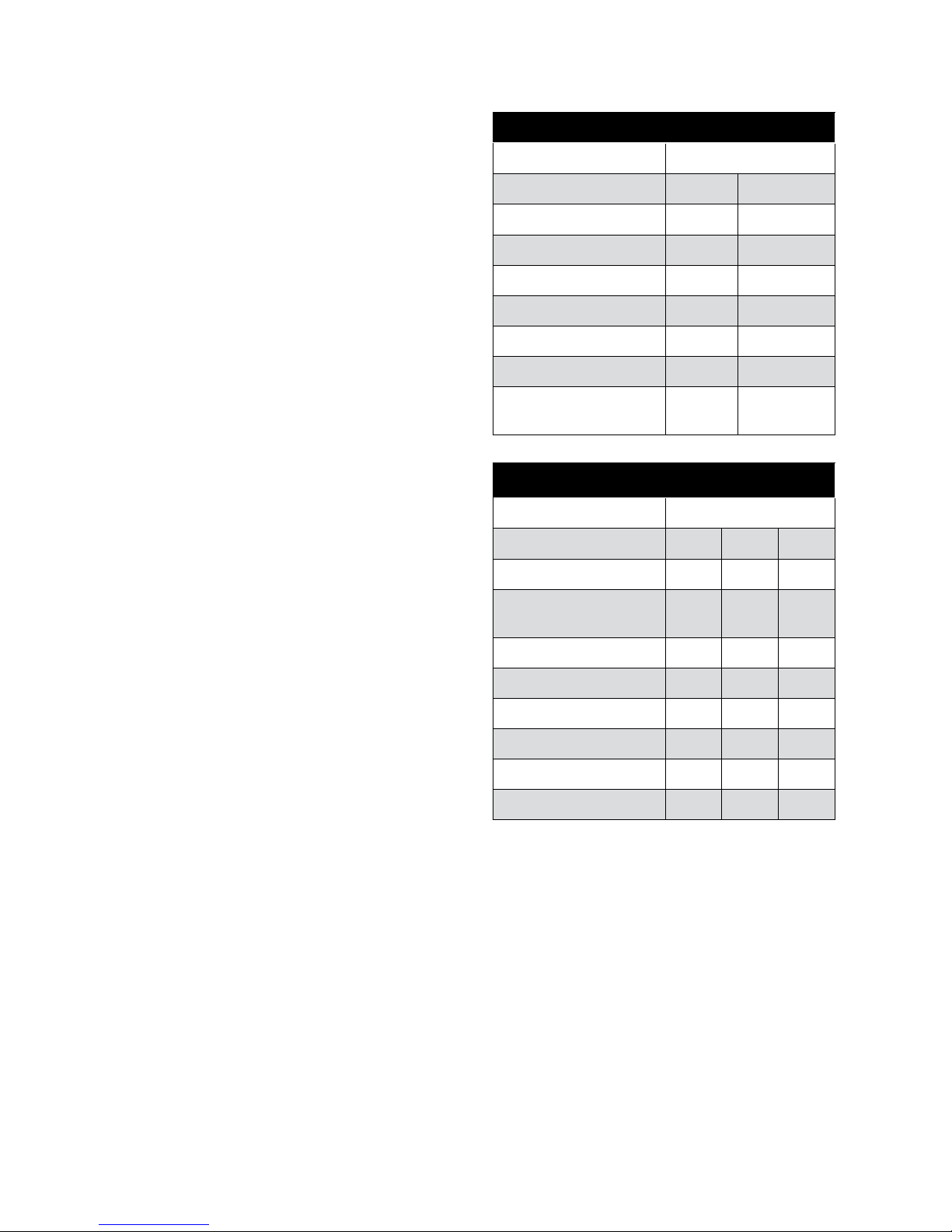

DuraPlus HTC Component Framing Dimensions

Square Ceiling Support Box 14-1/2" 370mm

Round Ceiling Support Box 14-1/4" 362mm

Reduced Clearance Support Box 12-1/4" 312mm

CAS Ceiling Support 14-1/2" 370mm

Wall Thimble 14-1/4" 362mm

CAS Wall Thimble 14-1/4" 362mm

Firestop Radiation Shield 14-1/2" 370mm

Reduced Clearance Firestop

Radiation Shield 12-1/4" 312mm

DuraPlus HTC Support Chimney Height Supported

6" 7" 8"

Square Ceiling Support Box 40-ft 40-ft 40-ft

Reduced Clearance Square

Ceiling Support Box 40-ft 40-ft 40-ft

CAS Ceiling Support Box 40-ft 40-ft 40-ft

Round Ceiling Support 40-ft 40-ft 40-ft

Roof Support 30-ft 30-ft 30-ft

Tee Support 35-ft 30-ft 25-ft

Tee Re-Support 30-ft 25-ft 25-ft

Extended Wall Bracket 35-ft 30-ft 25-ft