SET UP

Connect the PBF-510 to a 100 amp power supply. (208-

230 volts - 60 cycle). The PBF-510 unit uses 208-230 volt

single phase. To wire to 208-230 volt single phase, the green

lead is ground and the white and black leads are power. It is

suggested that the unit be permanently wired into a 100 amp

disconnect box fitted with 100 amp slow blow fuses.

ELECTRICAL REQUIREMENTS

PBF-510 AS A BENCH TOOL

Where the duct is too large to put on a bench, snap the

ground clamp onto the duct and secure the insulation quickly

by welding the Clip Pins inside or outside of the ducts as

required. Eliminate the heat mark on the duct by using the

simple “heat sink” included on opposite the side of weld.

WHEEL PBF-510 TO THE WORK

TIMER ADJUSTMENT

The PBF-510 has been designed and built to withstand rug-

ged shop usage. Constant, trouble-free operation is assured

with a minimum of maintenance. The GUN TIP, the GROUND

CLAMP and all CABLE CONNECTIONS should be kept clean to

maintain a good electrical contact. Wire brush the parts to

remove any oxidation or adhesive that may have accumulated

during the fastening operation.

"HEAT SINK"

The timer dial facing you on the front panel of the unit, deter-

mines the duration of the weld cycle. For maximum efficiency

of the unit, the weld cycle should be set for the shortest

length of time necessary to provide a good weld. An excessive

amount of time does not improve the weld. On the contrary,

the resulting weld may not be an acceptable one. It is recom-

mended that at the start of a production run, using a given

length of pin with a given gauge of metal, the operator take

a few moments to determine the minimum timer setting to

perform the job and leave the timer at that point.

NOTE: There is a common misconception that the longer the

weld time, the stronger the weld. This is not true. It is impor-

tant that you follow the above instructions for maintaining

the minimum weld time.

MAINTENANCE

Included with your PBF-510 is a simple “heat sink” tool that

looks somewhat like a cookie cutter. This tool, when placed

behind the point of weld on bare metal, will eliminate any mark

on the metal by dissipating the heat generated from the point

of weld. The use of a copper sheet on the work bench will also

eliminate this mark.

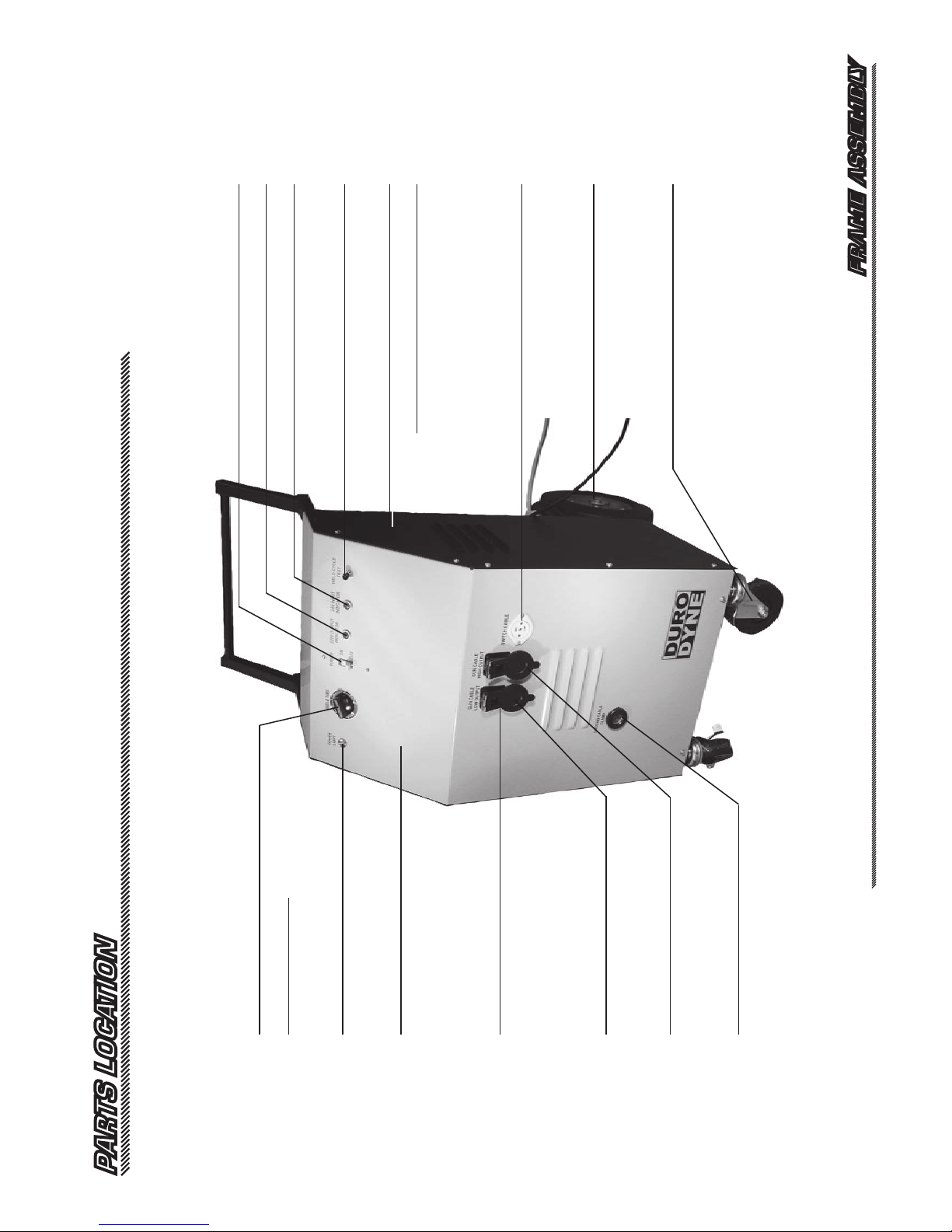

1. Plug the gun cable camlock

connector into either the high

or low gun female camlock (A).

(The HIGH tap produces about

10 volts, typically used for long

pins or heavy gauge material.

The LOW produces 5 volts,

typically used for light gauge

material.)

2. Plug the switch cable into the

switch cable socket (B).

3. Plug the ground cable cam

lock connector into the ground

female camlock (C).

To use your work bench as a welding table, set the PBF-510

alongside the work bench. Cover the bench top with a copper

sheet, (.025 inch) which will act as a permanent ground when

the duct work is placed on the table top. Attach the ground

clamp to the duct work or copper bench top. The Clip Pins

will quickly weld every time with no burn marks or wasted

pins due to misfires.

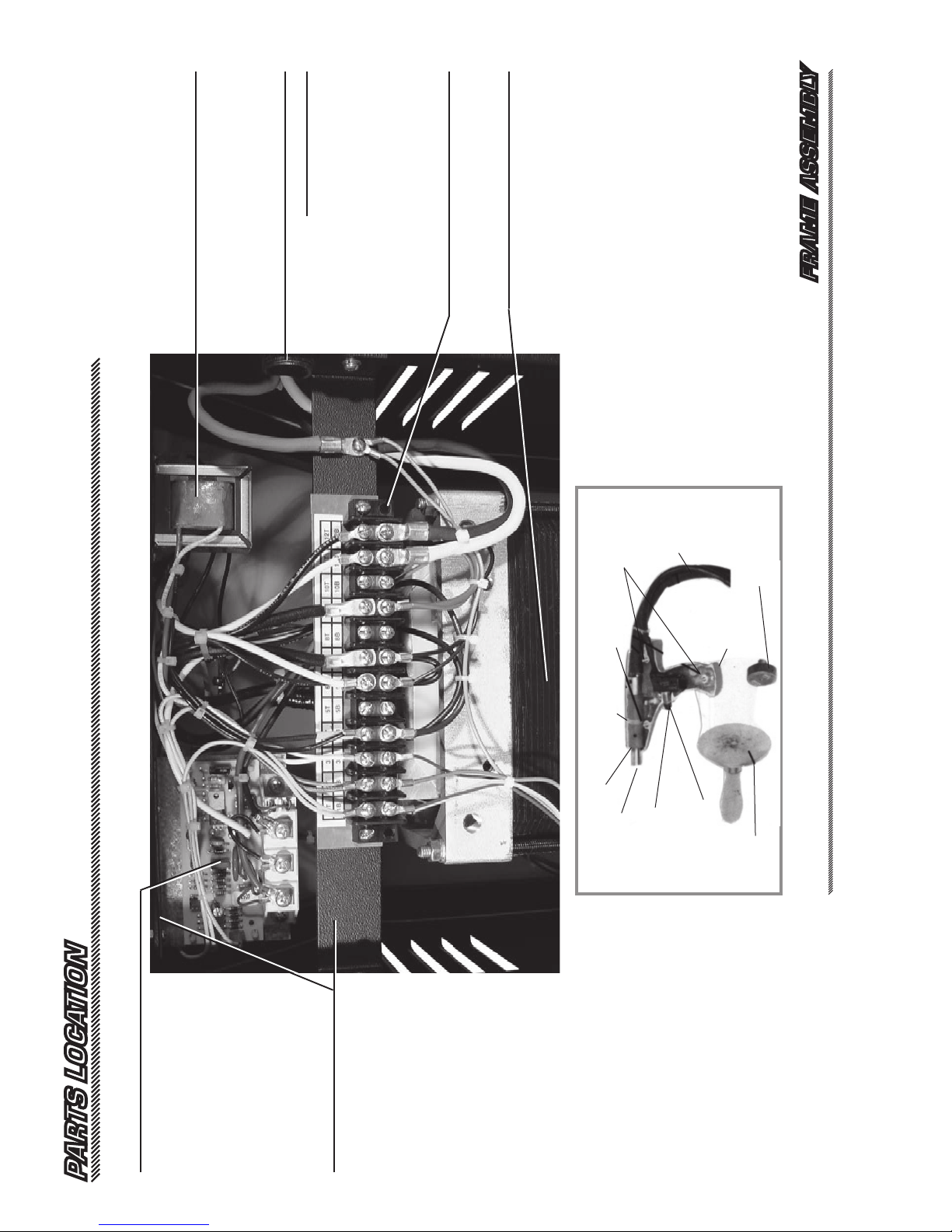

The PBF-510 has been designed and built to withstand rugged

shop usage. The Indicator lights on the front panel will help

you to diagnose minor problems. If your PBF-510 fails to

operate, follow this simple procedure to find the defective

component.

1.

Pull the trigger and watch the lights, the green light (24 volts)

and then the red light (220 volts) should flash on and off.

2. If only the green light comes on, go to step 4

3. If neither light comes on, press the WELD CYCLE TEST

switch on the front panel.

a. If both lights flash and the transformers do not hum go

to step 5.

b. If both lights flash and the transformers hum, the

problem is either a bad trigger switch or bad switch

cable.

c. If only the green light flashes, go to step 4

d. If neither light flashes, replace the 24 volt

transformer.

4. Replace the weld activator.

5. The problem is probably a bad weld transformer. Call

technical service for further assistance.

(1-800-899-3876)

SERVICE

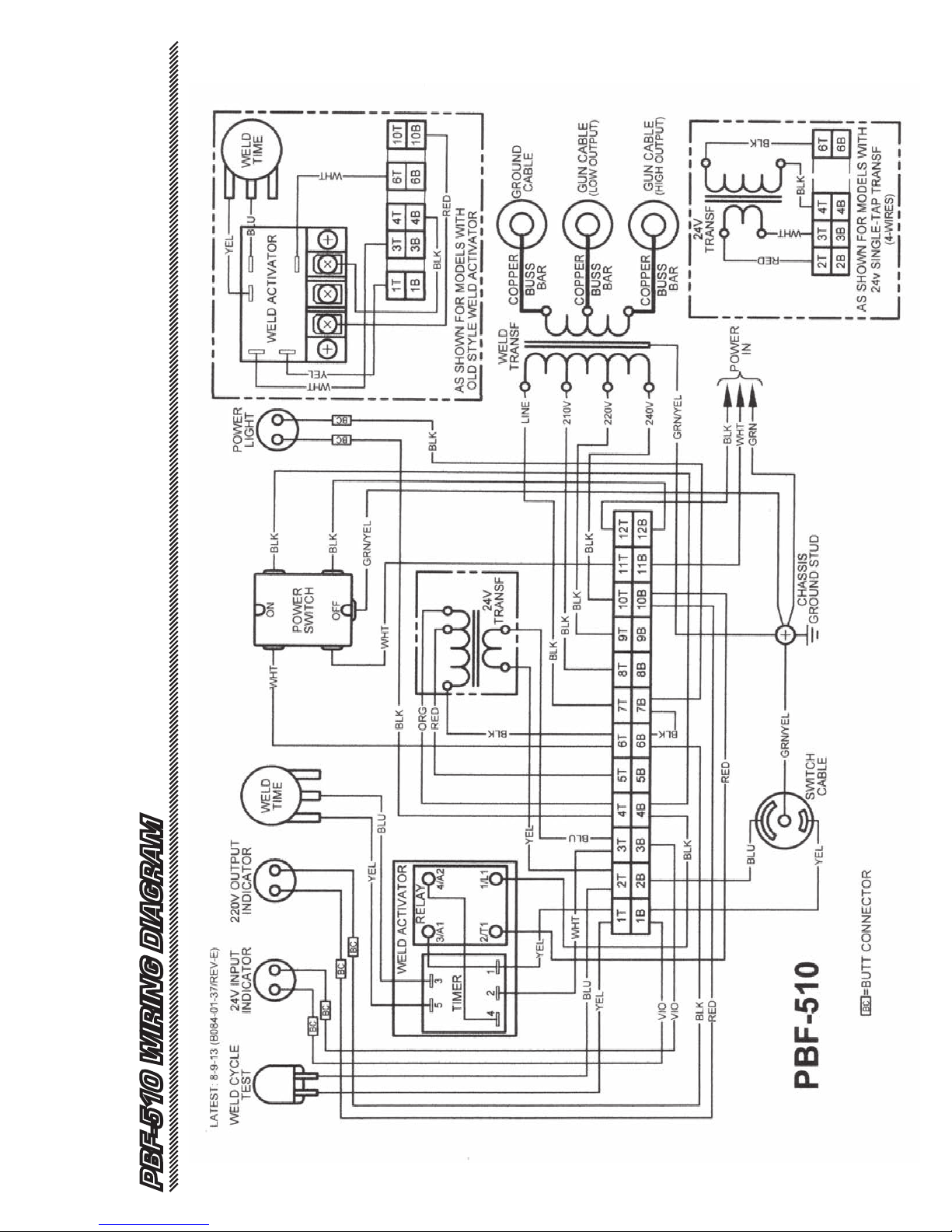

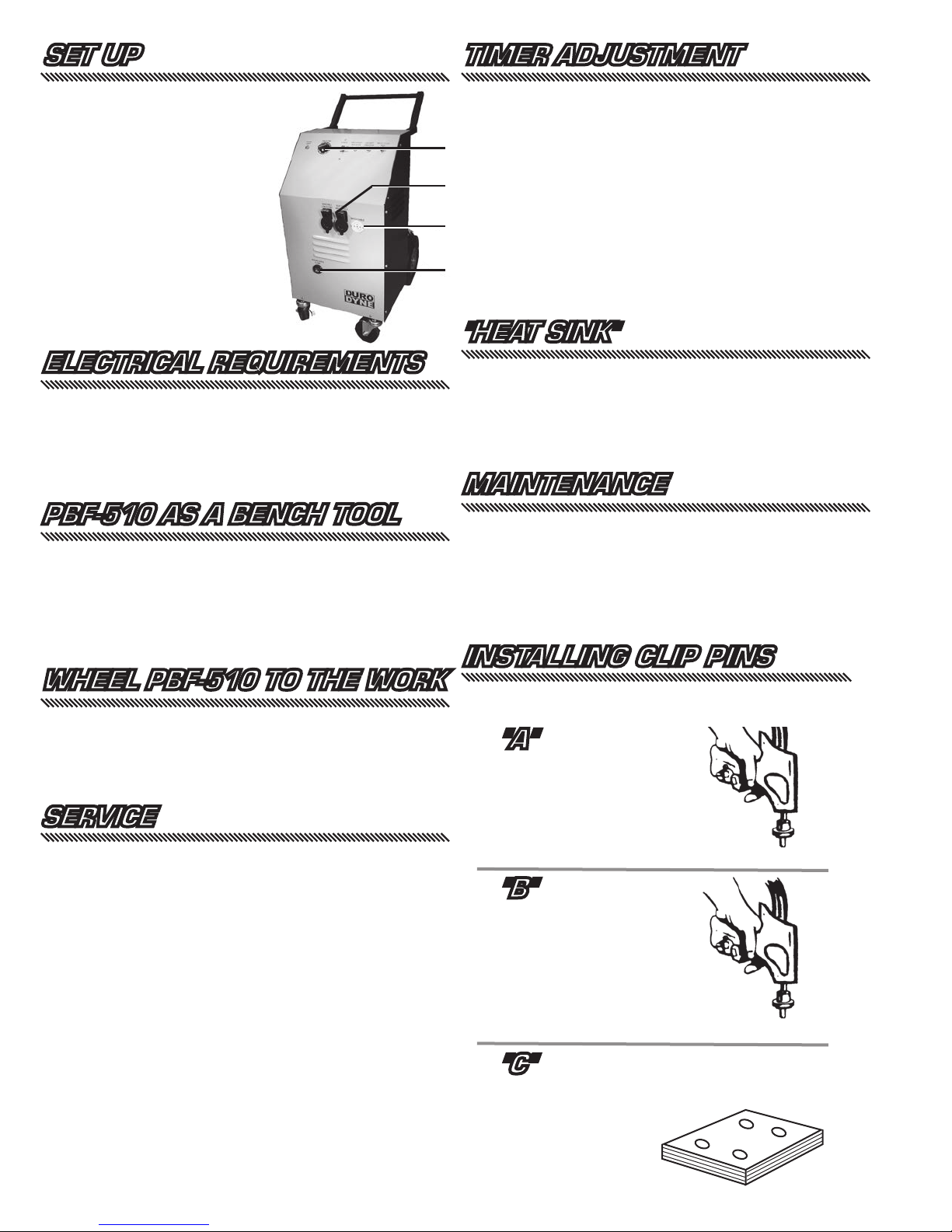

INSTALLING CLIP PINS

Clip Pins are welded as easily as "A", "B", "C".

"A"

Press down through the insu-

lation, twist the gun, pull the

trigger. Do not release the

trigger until the timer cycle

has ended.

"B"

Position the Clip pin on the

Magnetic tip of hand gun.

The Clip Pins are permanently

welded in position flush with the

insulation.

"C"

B

Timer

PBF-510

A

C