CONTENTS

SAFETYPRECAUTIONS............................................................................................................................................2

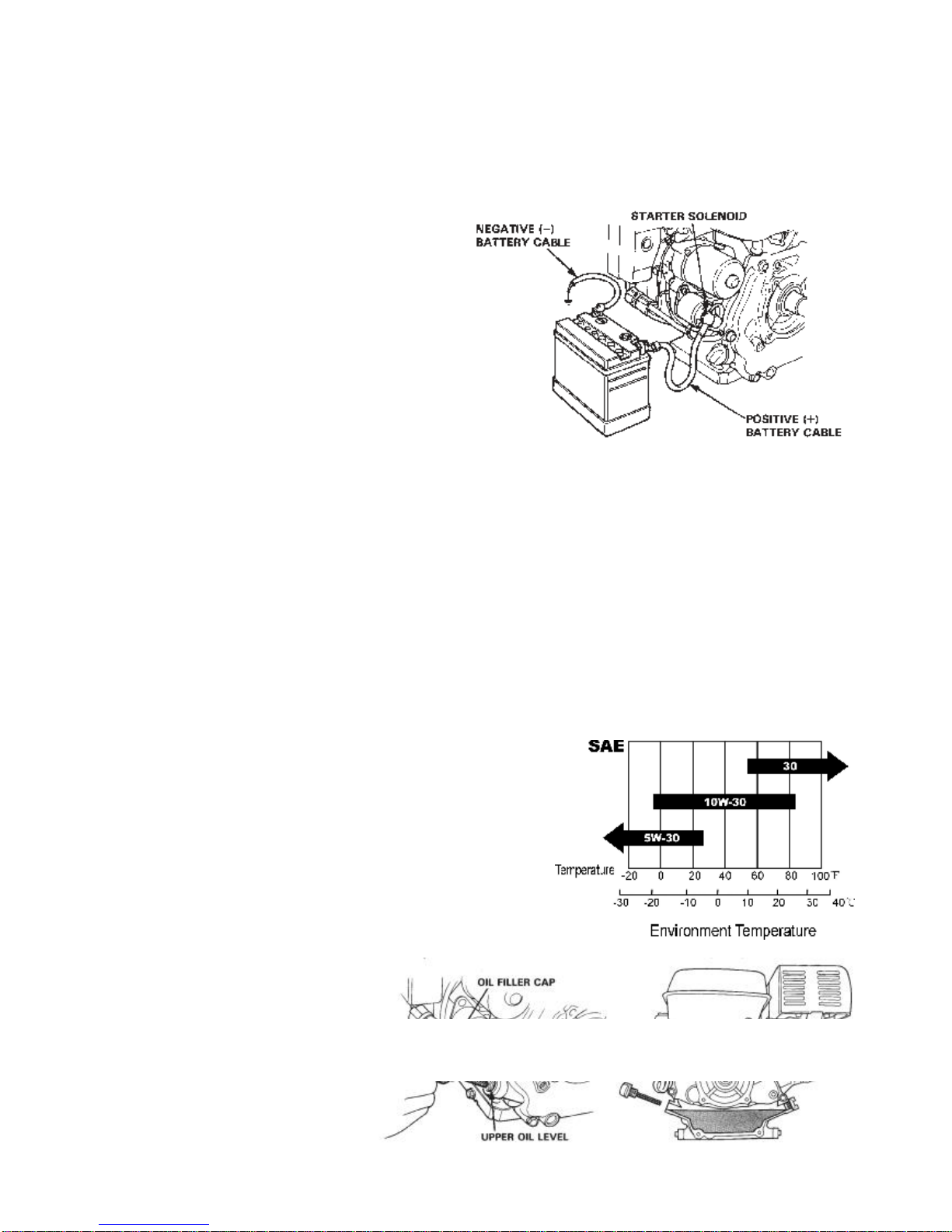

BATTERYCONNECTION(electric-start type)..........................................................................................................4

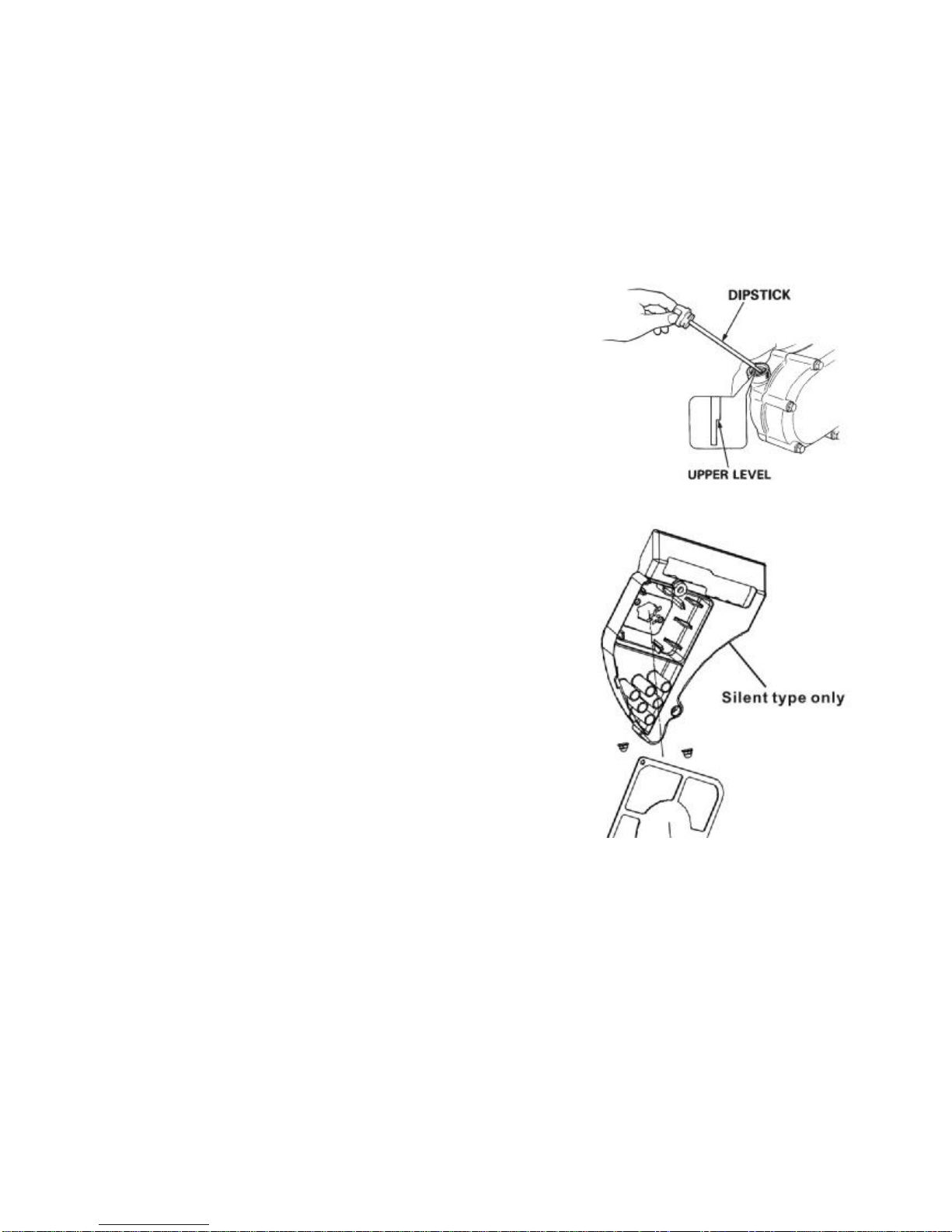

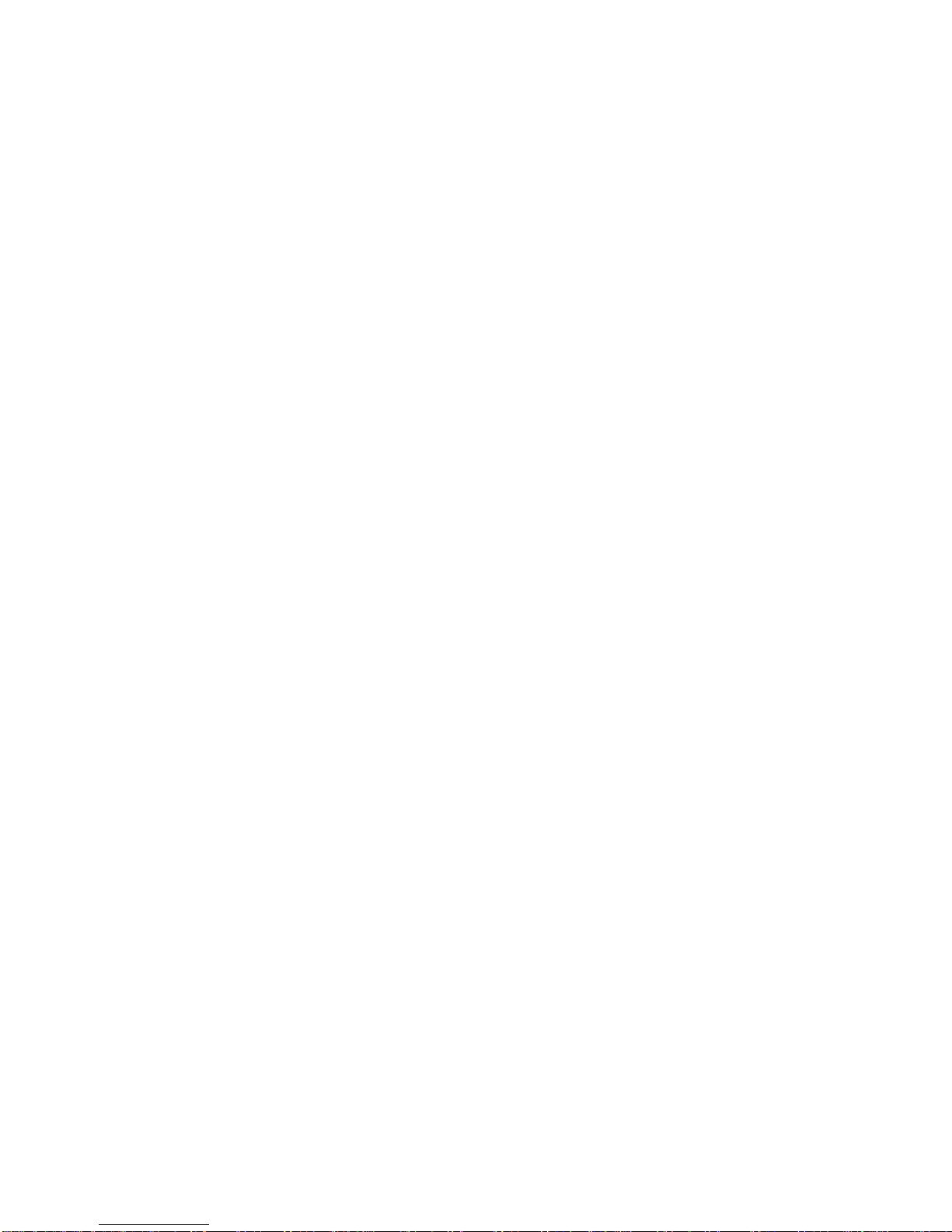

ENGINEOIL...........................................................................................................................................................4

FUELAND FUELTANK........................................................................................................................................6

STARTING THEENGINE ............................................................................................................................................7

RUNNINGTHEENGINE..............................................................................................................................................8

EXHAUSTCONTROLSYSTEM.................................................................................................................................9

MAINTENANCE...........................................................................................................................................................10

MAINTENANCESCHEDULE............................................................................................................................10

SPARKPLUG ......................................................................................................................................................13

TRANSPORT,STORAGEAND REMOVALFROMSTORAGE...........................................................................15

TRANSPORT.......................................................................................................................................................15

STORAGE............................................................................................................................................................15

REMOVALFROMSTORAGE...........................................................................................................................16

TROUBLESHOOTING ...............................................................................................................................................17

PARTSDESCRIPTIONS ..............................................................................................................................................3

PRE-OPERATION INSPECTION................................................................................................................................4

OPERATING AT HIGH ALTITUDE......................................................................................................................9

SHUTTING DOWN.........................................................................................................................................................9

CHANGING THE ENGINEOIL..........................................................................................................................11

LOW OIL SENSOR.................................................................................................................................................8

CLEANING THE AIRCLEANER........................................................................................................................12

CLEANING THE DEPOSITCUP.......................................................................................................................13

CARBURETORIDLE ADJUSTMENT...............................................................................................................14

SPECIFICATIONS.......................................................................................................................................................17

I. STARTENGINEDIFFICULTLY......................................................................................................................17

SERVICE AFTER STORAGE............................................................................................................................16

IV. STOPS SUDDENLYWHENRUNNING......................................................................................................20

III. GASOLINEENGINEWILL NOT RUN SMOOTHLY.................................................................................19

EXPLODEDVIEWANDPARTSLIST(16HP)..........................................................................................................27

EXPLODEDVIEWANDPARTSLIST(7HP)............................................................................................................24

VI. THEREIS ABNORMAL NOISE WHENENGINERUNNING..................................................................21

V. GASOLINEENGINEISEXCESSIVELYHOT............................................................................................20

II. LOWGASOLINEENGINEPOWEROUTPUT...........................................................................................19

WIRING DIAGRAM.....................................................................................................................................................22