Contents

Important information

1About this document .. . . . . . . . . . . . . 3

1.1 Warnings and symbols .. . . . . . . 3

1.2 Copyright information .. . . . . . . . 4

2 Safety .. . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 Intended purpose .. . . . . . . . . . . 4

2.2 Intended use .. . . . . . . . . . . . . . . 4

2.3 Improper use .. . . . . . . . . . . . . . . 4

2.4 General safety information .. . . . . 5

2.5 Specialist personnel .. . . . . . . . . 5

2.6 Electrical safety .. . . . . . . . . . . . . 5

2.7 Notification requirement of seri-

ous incidents .. . . . . . . . . . . . . . . 5

2.8 Only use original parts .. . . . . . . . 5

2.9 Transport .. . . . . . . . . . . . . . . . . . 5

2.10 Disposal .. . . . . . . . . . . . . . . . . . 6

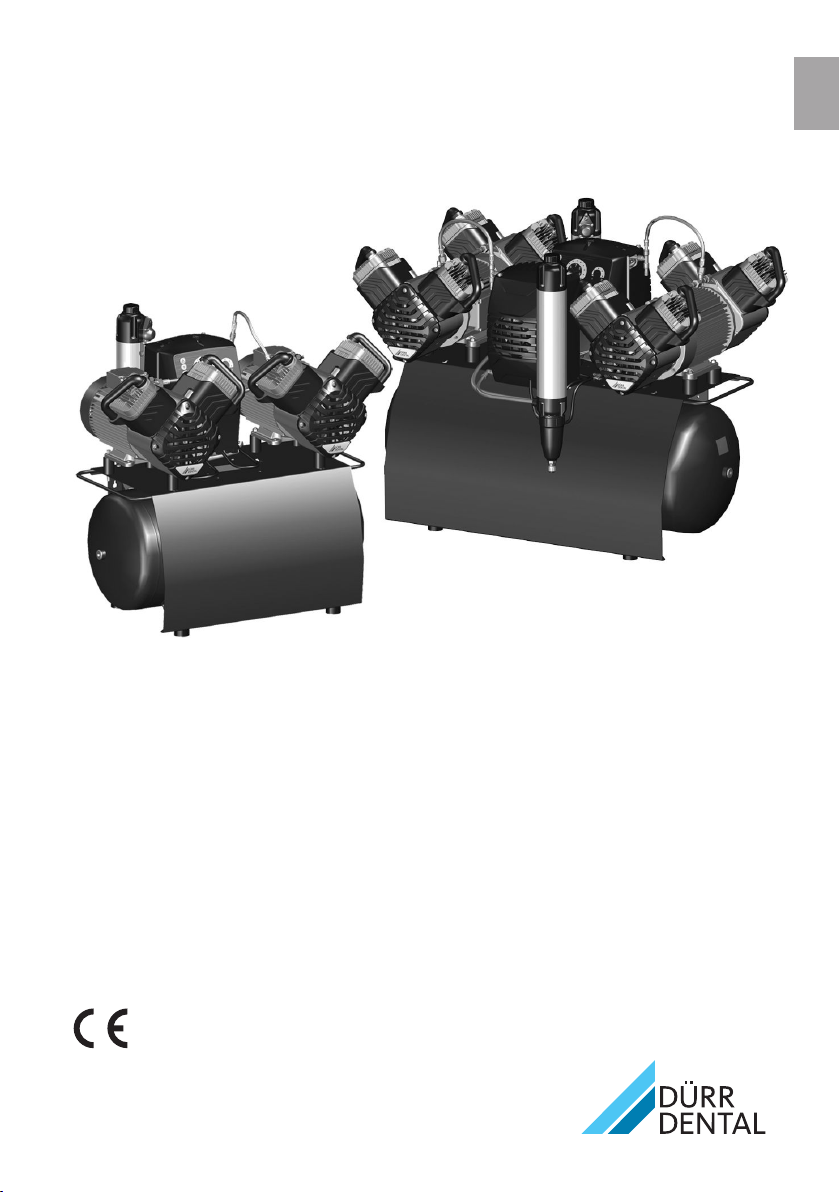

Product description

3Overview .. . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Scope of delivery .. . . . . . . . . . . . 7

3.2 Optional items .. . . . . . . . . . . . . . 7

3.3 Wear parts and replacement

parts .. . . . . . . . . . . . . . . . . . . . . 7

4Technical data .. . . . . . . . . . . . . . . . . . . 8

4.1 Duo Tandem .. . . . . . . . . . . . . . . 8

4.2 Duo Tandem .. . . . . . . . . . . . . . . 10

4.3 Quattro Tandem .. . . . . . . . . . . . 12

4.4 Distance between rubber feet .. . 14

4.5 Type plate .. . . . . . . . . . . . . . . . . 14

4.6 Evaluation of conformity .. . . . . . 14

5 Operation .. . . . . . . . . . . . . . . . . . . . . . 15

5.1 Duo Tandem / Quattro Tandem .. 15

5.2 Start-up behaviour .. . . . . . . . . . 16

5.3 Operating panel .. . . . . . . . . . . . . 16

Assembly

6 Requirements .. . . . . . . . . . . . . . . . . . . 17

6.1 Installation/setup room .. . . . . . . 17

6.2 Setup .. . . . . . . . . . . . . . . . . . . . 17

6.3 Information about electrical con-

nections .. . . . . . . . . . . . . . . . . . 17

7 Transport .. . . . . . . . . . . . . . . . . . . . . . . 18

8 Installation .. . . . . . . . . . . . . . . . . . . . . . 18

8.1 Remove the transport locks .. . . 18

8.2 Installing the compressor unit .. . 18

8.3 Establishing the compressed air

connection .. . . . . . . . . . . . . . . . 20

8.4 Pressure reducer .. . . . . . . . . . . 20

8.5 Place a collector tray underneath .. 21

8.6 Network connection .. . . . . . . . . 21

8.7 Electrical connections .. . . . . . . . 21

8.8 Two devices in a single com-

pressed air network .. . . . . . . . . . 22

9 Commissioning .. . . . . . . . . . . . . . . . . . 23

9.1 Checking the switch-on/cut-off

pressure .. . . . . . . . . . . . . . . . . . 23

9.2 Checking the safety valve .. . . . . 23

9.3 Draining the condensation water .. 24

9.4 Adjusting the rate of flow at the

pressure reducer .. . . . . . . . . . . . 24

9.5 Monitoring the unit via the net-

work .. . . . . . . . . . . . . . . . . . . . . 25

10 Adjustment options .. . . . . . . . . . . . . . 26

10.1 Adjustment of the switch-on/cut

off pressure .. . . . . . . . . . . . . . . . 26

11 Controller .. . . . . . . . . . . . . . . . . . . . . . . 27

11.1 3/N/PE AC 400 V layout .. . . . . . 27

11.2 1/N/PE AC 230 V layout .. . . . . . 29

12 Media plan .. . . . . . . . . . . . . . . . . . . . . 30

12.1 3/N/PE AC 400 V layout .. . . . . . 30

12.2 1/N/PE AC 230 V layout .. . . . . . 30

Contents

4252100034L02 2105V002 1

EN