9000-610-72/30 1811V006 1

Assembly

6 Requirements� � � � � � � � � � � � � � � � � � � � 14

6�1 Installation/setup room � � � � � � � � � 14

6�2 Setup � � � � � � � � � � � � � � � � � � � � � � 14

6�3 Information about electrical

connections � � � � � � � � � � � � � � � � � 14

7 Transport � � � � � � � � � � � � � � � � � � � � � � � 15

8 Installation � � � � � � � � � � � � � � � � � � � � � � 15

8�1 Remove the transport locks � � � � � 15

8�2 Installing the compressor unit � � � � 15

8�3 Establishing the compressed air

connection � � � � � � � � � � � � � � � � � � 17

8�4 Pressure reducer � � � � � � � � � � � � � 18

8�5 Place a collector tray underneath � 18

8�6 Network connection � � � � � � � � � � � 18

8�7 Electrical connections � � � � � � � � � � 19

8�8 Two devices in a single

compressed air network � � � � � � � � 19

9 Commissioning� � � � � � � � � � � � � � � � � � � 20

9�1 Checking the switch-on/cut-off

pressure � � � � � � � � � � � � � � � � � � � � 20

9�2 Checking the safety valve � � � � � � � 20

9�3 Draining the condensation water � � 21

9�4 Adjusting the rate of flow at the

pressure reducer� � � � � � � � � � � � � � 21

9�5 Monitoring the device with Tyscor

Pulse � � � � � � � � � � � � � � � � � � � � � � 22

10 Adjustment options � � � � � � � � � � � � � � � 24

10�1 Adjustment of the switch-on/cut

off pressure � � � � � � � � � � � � � � � � � 24

11 Controller � � � � � � � � � � � � � � � � � � � � � � � 25

EN

Contents

Important information

1 About this document � � � � � � � � � � � � � � � 3

1�1 Warnings and symbols � � � � � � � � � � 3

1�2 Copyright information � � � � � � � � � � � 3

2 Safety � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

2�1 Intended purpose � � � � � � � � � � � � � � 4

2�2 Intended use� � � � � � � � � � � � � � � � � � 4

2�3 Improper use � � � � � � � � � � � � � � � � � 4

2�4 General safety information� � � � � � � � 4

2�5 Qualified personnel � � � � � � � � � � � � � 4

2�6 Electrical safety� � � � � � � � � � � � � � � � 4

2�7 Only use original parts� � � � � � � � � � � 4

2�8 Transport � � � � � � � � � � � � � � � � � � � � 5

2�9 Disposal � � � � � � � � � � � � � � � � � � � � � 5

Product description

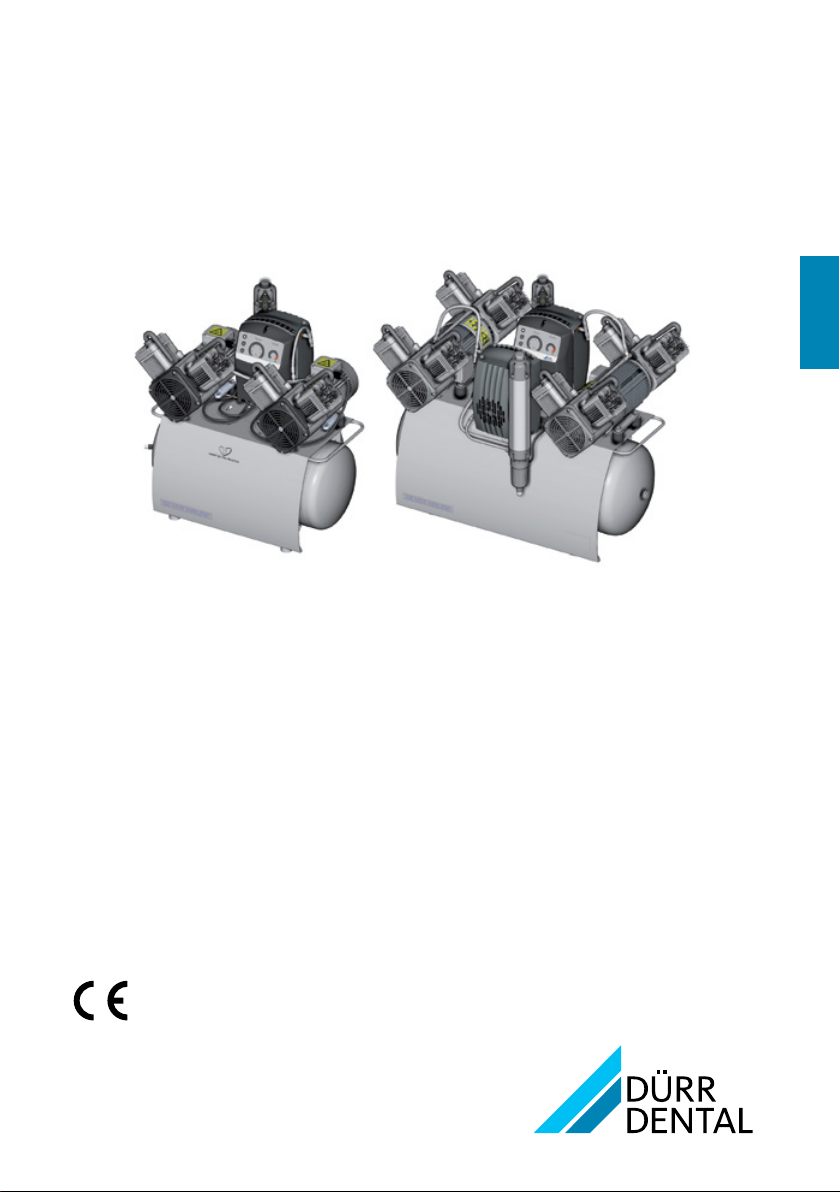

3 Overview� � � � � � � � � � � � � � � � � � � � � � � � � 6

3�1 Scope of delivery � � � � � � � � � � � � � � 6

3�2 Optional accessories� � � � � � � � � � � � 6

3�3 Wear parts and replacement

parts� � � � � � � � � � � � � � � � � � � � � � � � 6

4 Technical data � � � � � � � � � � � � � � � � � � � � 7

4�1 Duo Tandem� � � � � � � � � � � � � � � � � � 7

4�2 Quattro Tandem � � � � � � � � � � � � � � � 9

4�3 Distance between rubber feet � � � � 11

4�4 Type plate� � � � � � � � � � � � � � � � � � � 11

5 Operation � � � � � � � � � � � � � � � � � � � � � � � 12

5�1 Duo Tandem / Quattro Tandem� � � 12

5�2 Start-up behaviour � � � � � � � � � � � � 12

5�3 Operating panel � � � � � � � � � � � � � � 13

5�4 Tyscor Pulse (optional) � � � � � � � � � 13