6046100064L02 1702V002SE 1

7 Installation � � � � � � � � � � � � � � � � � � � � � � 17

7�1 Carrying the unit � � � � � � � � � � � � � � 17

7�2 Remove the transport locks � � � � � 17

7�3 Setting up the unit� � � � � � � � � � � � � 17

7�4 Removing the protective film from

the touch screen� � � � � � � � � � � � � � 18

7�5 Checking the SD memory card � � � 18

7�6 Checking the sterile air filter� � � � � � 18

7�7 Connecting the unit� � � � � � � � � � � � 19

7�8 Connecting the unit to the net-

work � � � � � � � � � � � � � � � � � � � � � � � 20

8 Configuring the unit � � � � � � � � � � � � � � � 22

8�1 Selecting the access level � � � � � � � 22

8�2 Entering dealer information � � � � � � 22

8�3 Language selection� � � � � � � � � � � � 22

8�4 Configuring the device with a

network connection � � � � � � � � � � � 22

8�5 Set the date and time�� � � � � � � � � � 22

8�6 Parameter selection � � � � � � � � � � � 23

8�7 Configuring a log printer � � � � � � � � 23

8�8 Configuring the label printer � � � � � 23

8�9 Configuring the network drive � � � � 23

8�10 User management � � � � � � � � � � � � 24

8�11 Setting up the calendar � � � � � � � � � 24

8�12 Touch screen � � � � � � � � � � � � � � � � 25

9 Monitoring the device with

Tyscor Pulse � � � � � � � � � � � � � � � � � � � � � 25

9�1 Network configuration � � � � � � � � � � 25

9�2 Network protocols and ports� � � � � 25

9�3 Add device � � � � � � � � � � � � � � � � � � 26

10 Test programs � � � � � � � � � � � � � � � � � � � 27

10�1 Vacuum test � � � � � � � � � � � � � � � � � 27

10�2 Bowie-Dick test � � � � � � � � � � � � � � 27

11 Logging handover and installation � � � � 28

12 Validation for commissioning � � � � � � � � 28

Operation

13 Operation � � � � � � � � � � � � � � � � � � � � � � � 30

13�1 Switching the unit on/off � � � � � � � � 30

13�2 Touch screen � � � � � � � � � � � � � � � � 30

13�3 Time preset� � � � � � � � � � � � � � � � � � 32

13�4 Monitoring the device with

Tyscor Pulse � � � � � � � � � � � � � � � � � 32

13�5 Opening and closing the door � � � � 33

EN

Contents

Important information

1 About this document � � � � � � � � � � � � � � � 3

1�1 Warnings and symbols � � � � � � � � � � 3

1�2 Copyright information � � � � � � � � � � � 3

2 Safety � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

2�1 Intended purpose � � � � � � � � � � � � � � 4

2�2 Intended use� � � � � � � � � � � � � � � � � � 4

2�3 Improper use � � � � � � � � � � � � � � � � � 4

2�4 General safety information� � � � � � � � 4

2�5 Applicable guidelines and

standards � � � � � � � � � � � � � � � � � � � � 4

2�6 Qualified personnel � � � � � � � � � � � � � 5

2�7 Protection from electric shock � � � � � 5

2�8 Only use genuine parts � � � � � � � � � � 5

2�9 Transport and packaging� � � � � � � � � 5

2�10 Disposal � � � � � � � � � � � � � � � � � � � � � 5

Product description

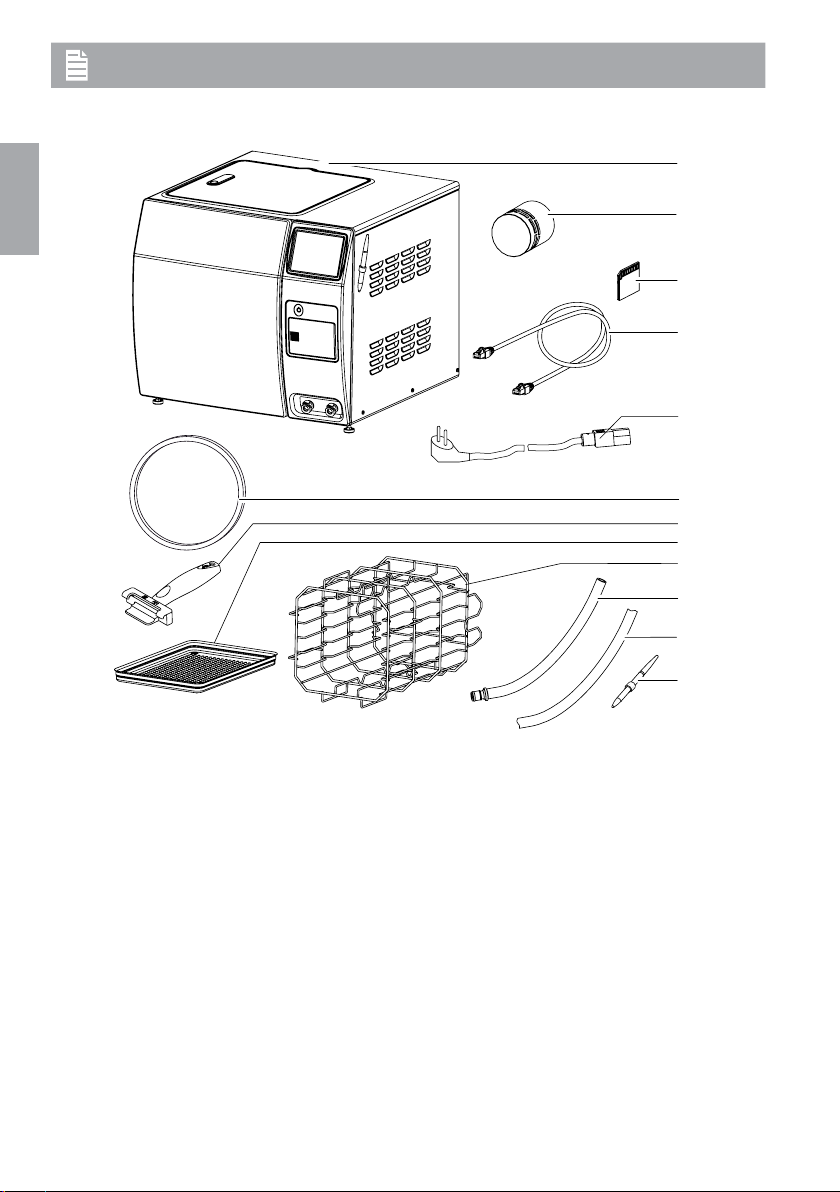

3 Overview� � � � � � � � � � � � � � � � � � � � � � � � � 6

3�1 Scope of delivery � � � � � � � � � � � � � � 7

3�2 Accessories � � � � � � � � � � � � � � � � � � 7

3�3 Special accessories � � � � � � � � � � � � 7

3�4 Disposable materials � � � � � � � � � � � � 7

3�5 Wear parts and spare parts� � � � � � � 7

4 Technical data � � � � � � � � � � � � � � � � � � � � 8

4�1 Type plate � � � � � � � � � � � � � � � � � � � 10

4�2 Conformity assessment� � � � � � � � � 10

5 Operation � � � � � � � � � � � � � � � � � � � � � � � 11

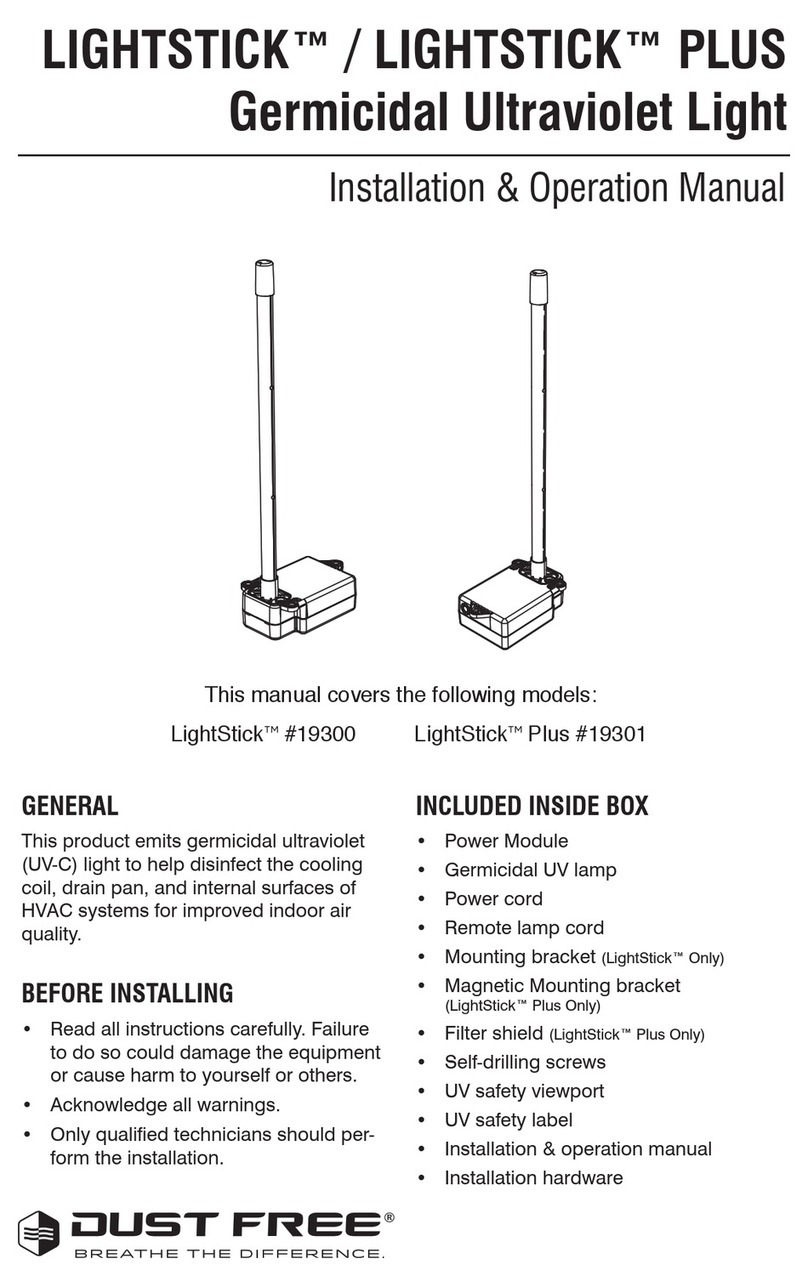

5�1 Hygoclave 90 � � � � � � � � � � � � � � � � 11

5�2 Safety devices � � � � � � � � � � � � � � � 13

5�3 Overview of programs � � � � � � � � � � 15

5�4 Tyscor Pulse (optional) � � � � � � � � � 15

Installation

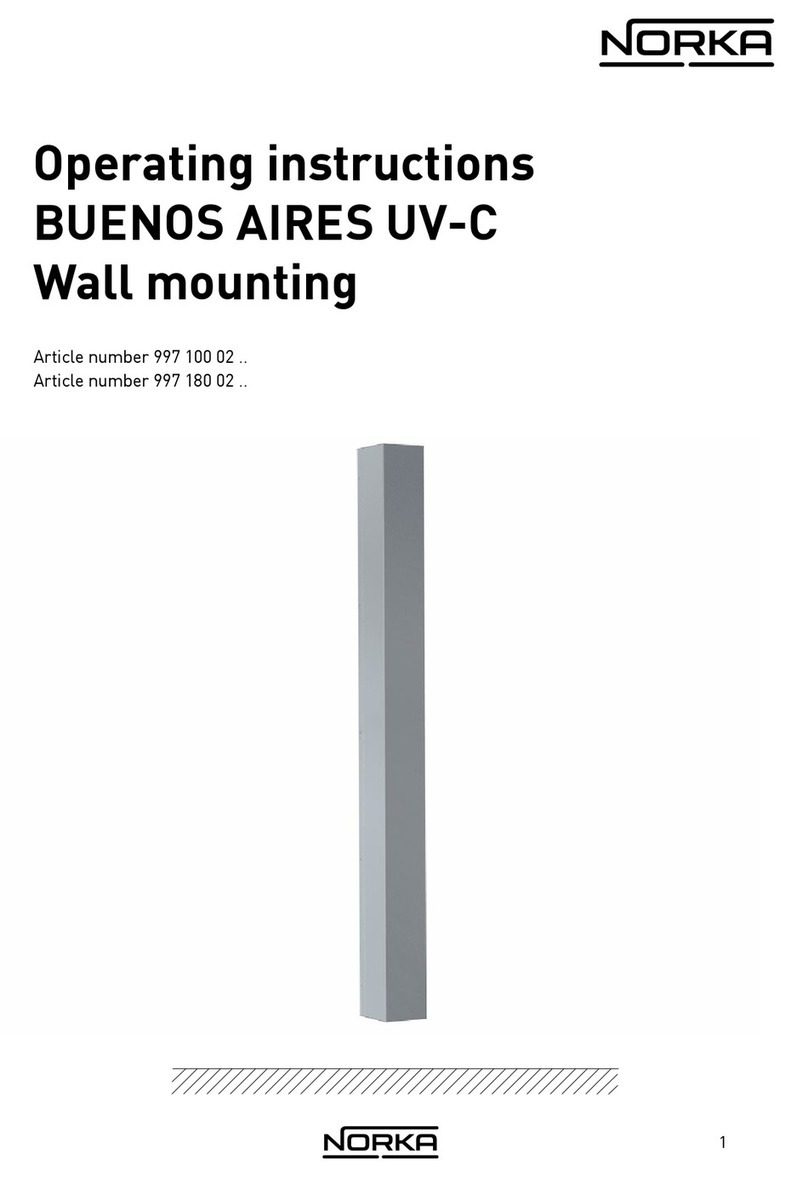

6 Requirements � � � � � � � � � � � � � � � � � � � � 17

6�1 Installation/setup room � � � � � � � � � 17