©Copyright 2003 Dwyer Instruments, Inc. Printed in U.S.A. 10/03 FR# 440306-00 Rev. 10

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. Box 373 • Michigan City, IN 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

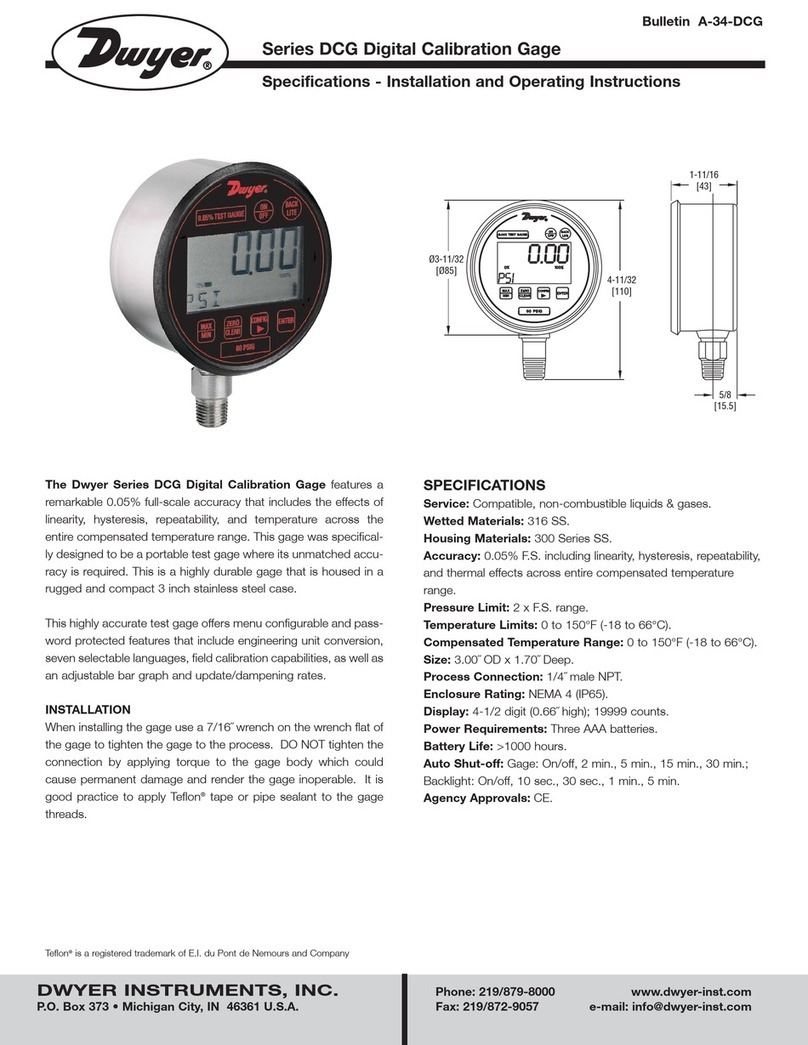

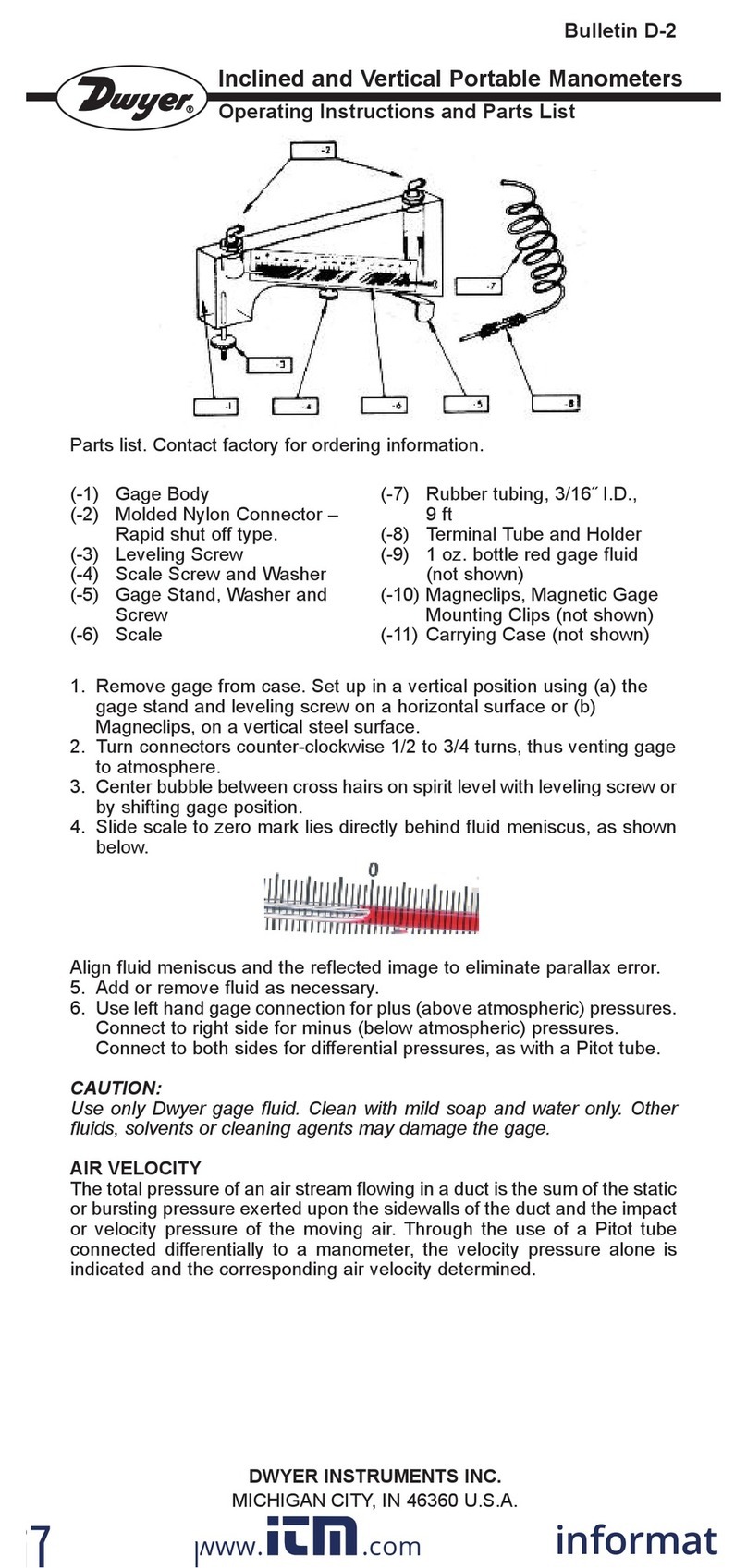

3. Surface Mounting

Locate 4 mounting holes, 35˚ from horizontal centerline on

a 4-11/32˝ dia. circle. Use No. 6-32 machine screws of

appropriate length. Be sure to drill 1/4˝ holes for blowout

protection as shown in the diagram.

4. Flush Mounting

Provide a 4-13/16˝ dia. opening in panel. Insert gage and

secure in place with No. 6-32 machine screws of appropri-

ate length, with mounting lugs firmly secured in place.

5. To zero the gage after Installation

Set the indicating pointer exactly on the zero mark, using

the external zero adjust screw on the cover at the bottom.

Note that the zero check or adjustment can only be made

with the high and low pressure taps both open to atmos-

phere.

CAUTION

Note location of blowout or vent holes in the surface

mounting diagram. Do not block these holes as their func-

tion is to vent overpressure failure out the back of the gage

rather than blowing off the front cover.

Important Notes:

Two pairs of high and low pressure taps are provided, one

pair on the top and a duplicate pair on the bottom. These

fittings may be utilized according to the type of service for

which the gage will be used. For gas or vapor service the

gage should be connected from the pressure source to the

top pressure fittings so that any accumulation of conden-

sate may be drained or bled out the bottom fittings. For liq-

uid service the pressure source should bee connected to

the bottom taps so that any trapped gas may be vented out

the top fittings. Optional bleed fittings may be obtained to

replace the standard 1/4NPT plugs for installations requiring

frequent draining or venting of the gage. Note that the

unused pair of pressure taps must be plugged in order for

the gage to operate. For straight pressure or vacuum appli-

cations where only one of a pair of high and low pressure

taps are being utilized, the other tap must be open to

atmosphere.

For portable use or temporary installation use 1/4male NPT

to male flare fitting and connect to pressure source with

high pressure hose or tubing will flare nut connectors.

For permanent installation 1/4˝ OD copper or stainless steel

tubing is recommended.

Proper installation of fittings and plugs is important.

Sparingly apply pipe thread sealant to threads. Excessive

amounts can fall into pressure passages and cause block-

age. we recommend Loctite®69-31 Hydraulic Sealant.

Install using torque wrench. Tighten only to 20 ft/lbs. Over-

tightening can damage case.

CAPSUHELIC®MAINTENANCE

Note: Capsuhelic®differential pressure gages are high pre-

cision instruments assembled and calibrated in a modern

factory. If trained instrument mechanics are not available,

we recommend that any instruments requiring repair be

returned to the factory.

1. No lubrication or periodic servicing is required. If the inte-

rior is protected from dust, dirt, corrosive gases and fluids,

years of trouble free service may be expected.

2. For service requiring a high degree of continued accura-

cy, periodic calibration checks are recommended. Send

back to the factory for re-calibration.

A-32 10/20/03 9:05 AM Page 2