Global Water

800-876-1172 •globalw.com

6

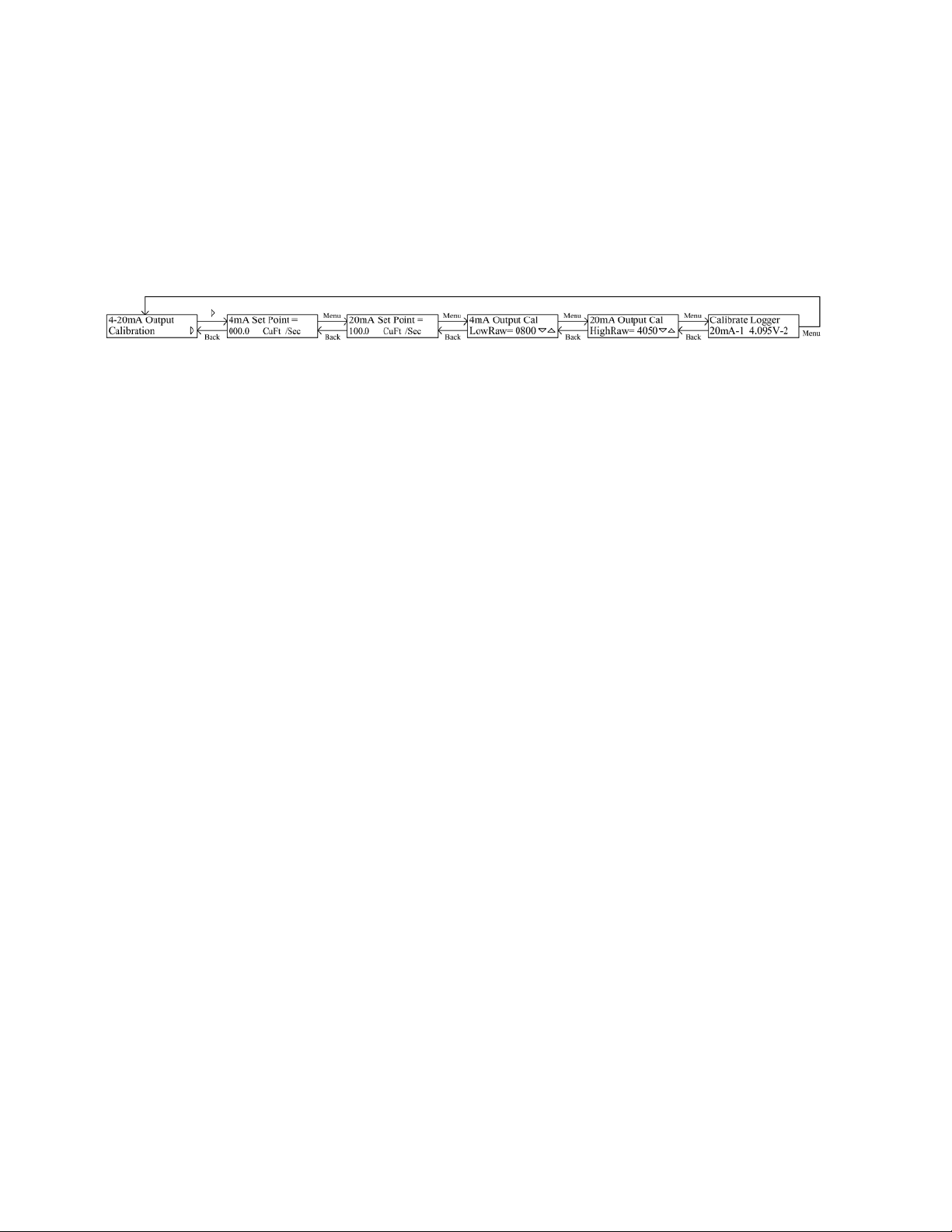

Before proceeding, make sure that the FC220 or PC320 4-20mA Output

Calibration process has already been completed as described in the previous

section. On the FC220 or PC320, enter the setup menus and scroll down to the

output calibration menu. Note that within 1 minute of the last button press, the

FC220 and PC320 will automatically exit the setup menus. If this happens during

the calibration process, return to the setup menu.

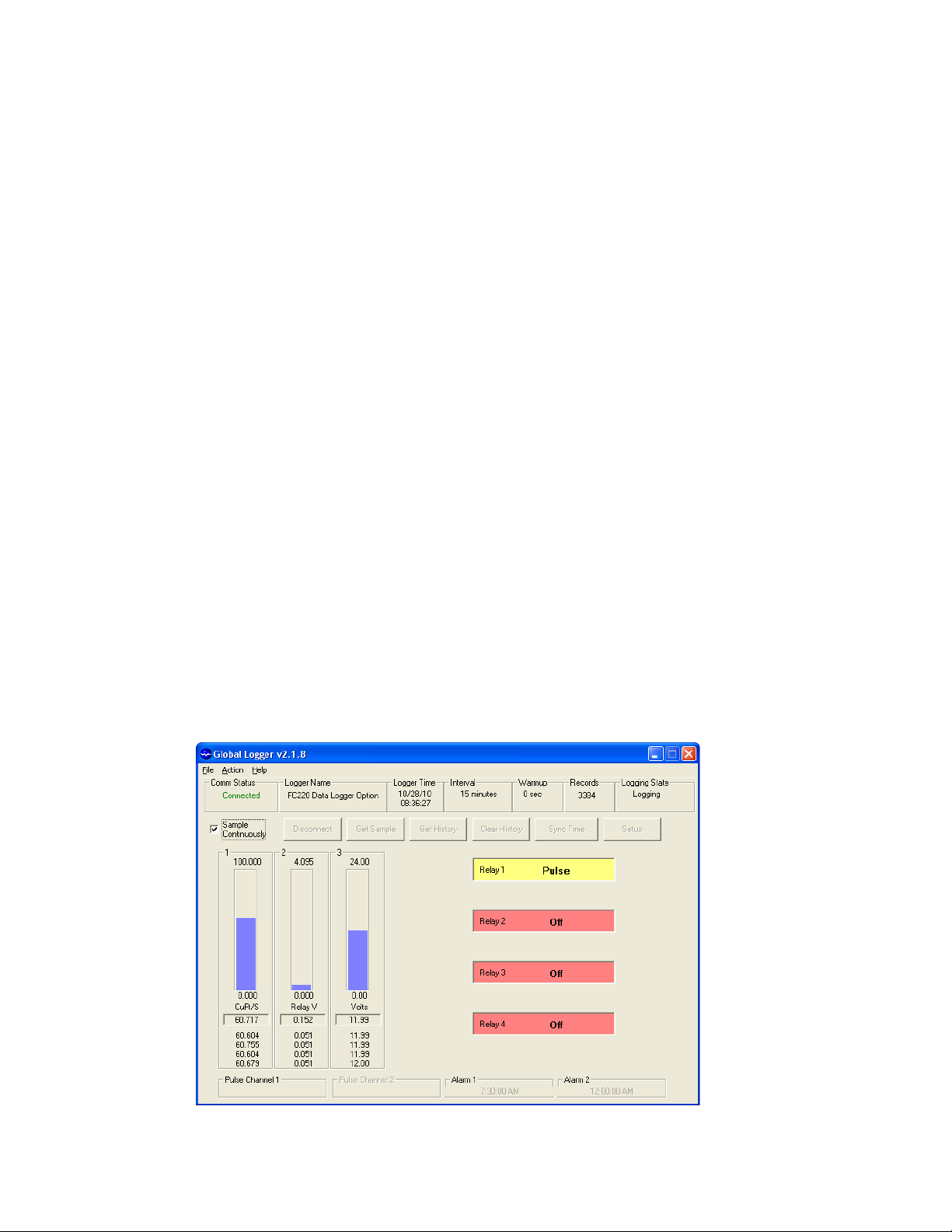

Calibrating Channel One

Enter the sub-menus and note the 4mA and 20mA Setpoints. Using the MENU

button, advance to the 20mA Output Cal menu. From the Global Logger II

software, click the Calibrate button at the bottom of the Channel 1 field in the

Analog Channels tab. In the first of four calibration screens, enter the value of the

20mA Set Point programmed into the FC220 or PC320, then click Next. When the

value has settled, click Next again. On the FC220 or PC320, press the BACK

button to return to the 4mA Output Cal menu. In the Channel 1 Calibrate screen of

Global Logger II, Enter the value of the 4mA Set Point programmed into the

FC220 or PC320, then click Next. When the value has settled, click Next. Enter

the engineering units into the Units field that correspond to the units used in the

4mA and 20mA Set Points in the FC220 or PC320. The Display High Value and

Low Value fields are used to set the range of the bar graph of the main display only,

they are not part of the calibration process. Enter values to scale the bar graph to

the desired range.

Calibrating Channel 2

On the FC220 or PC320, advance to the “Calibrate Logger 20mA-1 4.095V-2”

menu. In the Analog Channels setup menu of Global Logger II, click the Calibrate

button for channel 2. For the High Engineering Value, enter 4.095 and click next.

When the value has settled, click Next again. Enter zero into the Low Engineering

Value, then click Next. Click Next one more time to exit the calibration menus.

Click on the Low Raw Value box and enter zero. In the Display High Value box,

enter 4.095. In the Display Low Value, enter zero. For the Channel 2 Units, enter

Volts. Select the desired number of decimal places for channel 1, select 3 decimal

places for channel 2. Click the Program Settings button to program the logger.

Click the Back to Main Window button to return to the main screen. The

calibration process is complete.