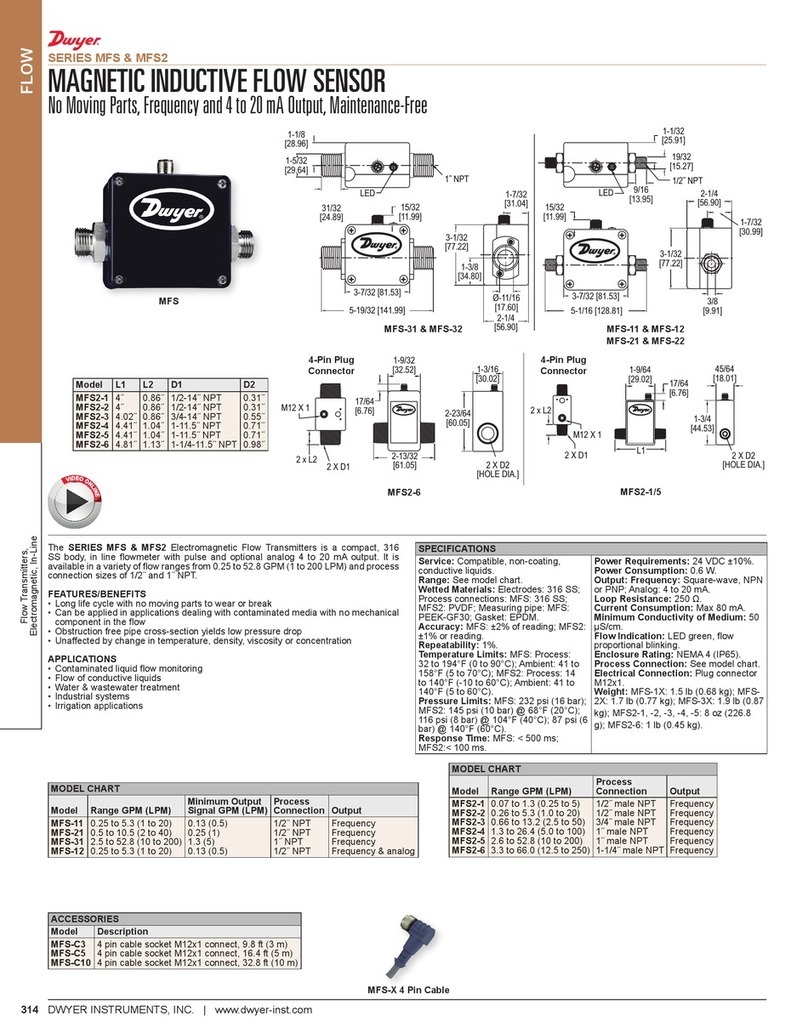

Fig. 3 Fig. 4

Fig. 5 Fig. 6

Fig. 7

Fig. 5B Fig. 6B

Surface Mounting: Drill appropriate holes in panel, using the dimensions

shown in Fig. 2. Hold the flowmeter in position in front of the panel and

install the clamp bolts from the rear. (The mounting clamps may be used

as washers, if desired, by installing them backwards or straightening them

out.) Pipe up inlet and discharge following the directions in the previous

sections.

Surface Mounting on Piping Only: An alternate method of surface

mounting, omitting the clamp bolts and supporting the flowmeter solely on

the connecting piping, is possible. For this method, extra-long or straight

pipe threads should be used so that nuts may be run onto the pipe and

later tightened against the back of the panel to retain the unit in proper

position. Use appropriate hole layout in formation from Fig. 2, but omit the

small holes.

Surface Mounting on Piping Only Without Panel: For a temporary or

laboratory type installation, the panel may be omitted altogether and the

flowmeter installed directly in rigid piping. Its light weight permits this with-

out difficulty.

OPERATION

To start system, open valve slowly to avoid possible damage. Control

valves on BV and SSV models are turned clockwise to reduce flow,

counter-clockwise to increase flow. A nylon insert is provided in the thread-

ed section of the valve stem to give a firm touch to valve and to prevent

change of setting due to vibration.

The performance of low range units used in air or gas applications may be

affected by static electricity. Excessive static charge may cause the ball

float to behave erratically or provide a false reading. To ensure the proper

function of the unit, the application should be designed to minimize or dis-

pel static electricity.

The standard technique for reading a Variable Area Flowmeter is to locate

the highest point of greatest diameter on the float, and then align that with

the theoretical center of the scale graduation. In the event that the float is

not aligned with a grad, an extrapolation of the float location must be made

by the operator as to its location between the two closest grads. The fol-

lowing are some sample floats shown with reference to the proper location

to read the float.

Variable Area Flowmeters used for gases are typically labeled with the pre-

fix “S” or “N”, which represents “Standard” for English units or “Normal” for

metric units. Use of this prefix designates that the flowmeter is calibrated

to operate at a specific set of conditions, and deviation from those stan-

dard conditions will require correction for the calibration to be valid. In prac-

tice, the reading taken from the flowmeter scale must be corrected back to

standard conditions to be used with the scale units. The correct location to

measure the actual pressure and temperature is at the exit of the flowme-

ter, except when using the Top Mounted Valve under vacuum applications,

where they should be measured at the flowmeter inlet. The equation to cor-

rect for nonstandard operating conditions is as follows:

Q2= Q1x P1x T2

P2x T1

Where: Q1= Actual or Observed Flowmeter Reading

Q2= Standard Flow Corrected for Pressure and

Temperature

P1= Actual Pressure (14.7 psia + Gage Pressure)

P2= Standard Pressure (14.7 psia, which is 0 psig)

T1= Actual Temperature (460 R + Temp °F)

T2= Standard Temperature (530 R, which is 70°F)

Example: A flowmeter with a scale of 10-100 SCFH Air. The float is sitting

at the 60 grad on the flowmeter scale. Actual Pressure is measured at the

exit of the meter as 5 psig. Actual Temperature is measured at the exit of

the meter as 85°F.

Q2= 60.0 x (14.7 + 5) x 530

14.7 x (460 + 85)

Q2= 68.5 SCFH Air

CAUTION: Do not completely unscrew valve stem unless the flowmeter is

unpressurized and drained of any liquid. Removal while in service will allow

gas or liquid to flow out the front of the valve body and could result in seri-

ous personal injury. For applications involving high pressure and/or toxic

gases or fluids, special non-removable valves are available on special

order. Please contact factory for details.

MAINTENANCE

The only maintenance normally required is occasional cleaning to assure

reliable operation and good float visibility.

Disassembly: The flowmeter can be disassembled for cleaning

simply as follows:

1. Remove valve knob from RMB or RMC -BV or -SSV units by pulling the

knob forward. It is retained by spring pressure on the stem half-shaft so

that a gentle pull will remove it. On RMA-BV or -SSV models, turn the valve

knob counter-clockwise until the threads are disengaged. Then withdraw

the stem from the valve by gently pulling on the knob.

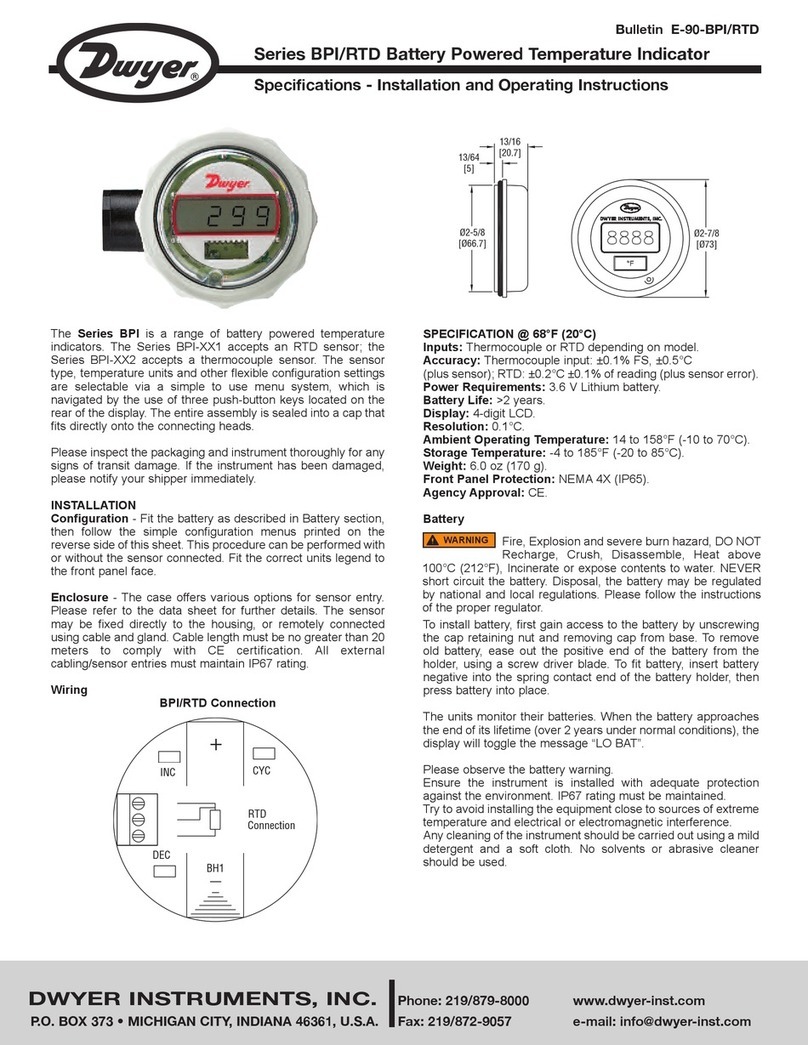

2. Remove the four mounting bracket screws located in the sides of the

flowmeter. See Fig. 3. Pull the flowmeter body gently forward away from

the back plate to avoid undue strain on the body. Leave the piping con-

nections intact. There is no need to disturb them. See Fig. 4.

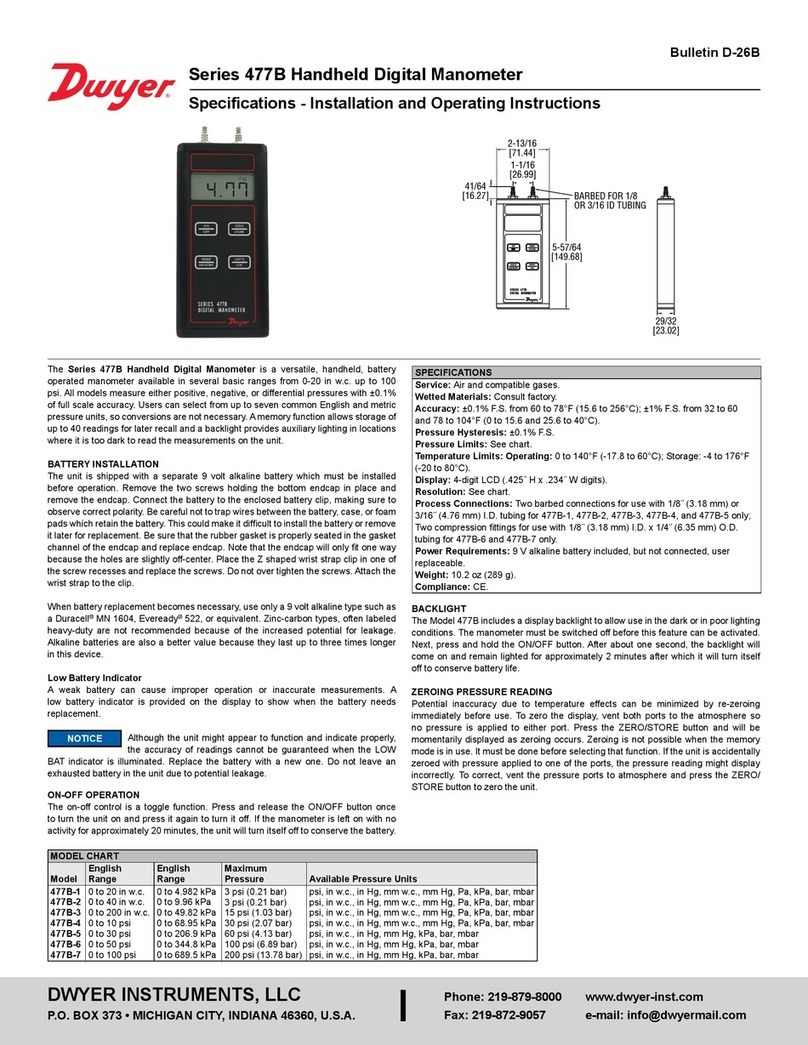

3. Threaded body style flowmeters - Remove the slip cap with a push on

a screwdriver as shown in Fig. 5. Remove the plug ball stop as shown in

Fig. 6 using allen wrench sizes as follows: Model RMA - 1/4″, Model RMB

- 1/2″and Model RMC - 3/4″Threadless body style flowmeters - Release

the plastic retaining clip with a screw driver (Figure 5B), it will unclip from

the valve body (TMV Option) or the plug ball stop, slide the clip back until

the valve body or ball stop can be removed. The clip will remain in the body

for convenience. Using a screwdriver gently lift up on the plug in the groove

as shown in Figure 6B until the o-ring seal is released and remove the plug.

For the TMV option gently pull up on the valve knob to release the valve

body seals and remove the valve.

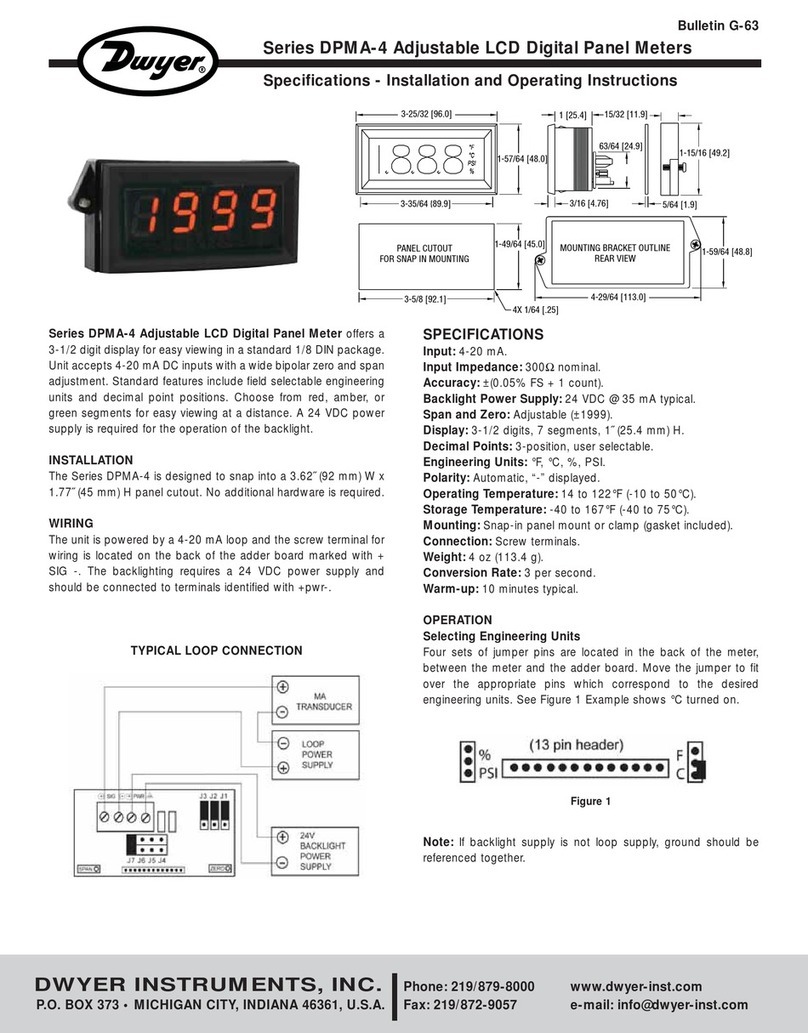

4. Take out the ball or float by inverting the body and allowing the float

to fall into your hand, as shown in Fig. 7. (Note: It is best to cover the dis-

charge port to avoid losing the float through that

opening.)

Cleaning: The flow tube and flowmeter body can best be cleaned with a

little pure soap and water. Use of a bottle brush or other soft brush will aid

the cleaning. Avoid benzene, acetone, carbon tetrachloride, alkaline deter-

gents, caustic soda, liquid soaps (which may contain chlorinated solvents),

etc. Also, avoid prolonged immersion, which may harm or loosen the

scale.

Reassembly: Simply reverse steps 1 through 4 and place the flowmeter

back in service. A little stopcock grease or petroleum jelly on the “O” rings

will help maintain a good seal as well as facilitate assembly. No other spe-

cial care is required.

MOUNTING

BRACKET

SCREW 4

REQUIRED

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, IN 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

©Copyright 2009 Dwyer Instruments, Inc. Printed in U.S.A. 7/09 FR# 56-440197-00 Rev. 17

Teflon® is a registered Trademark of E.I. DuPont Company

F-43:Bulletin F-43 7/30/09 10:57 AM Page 2