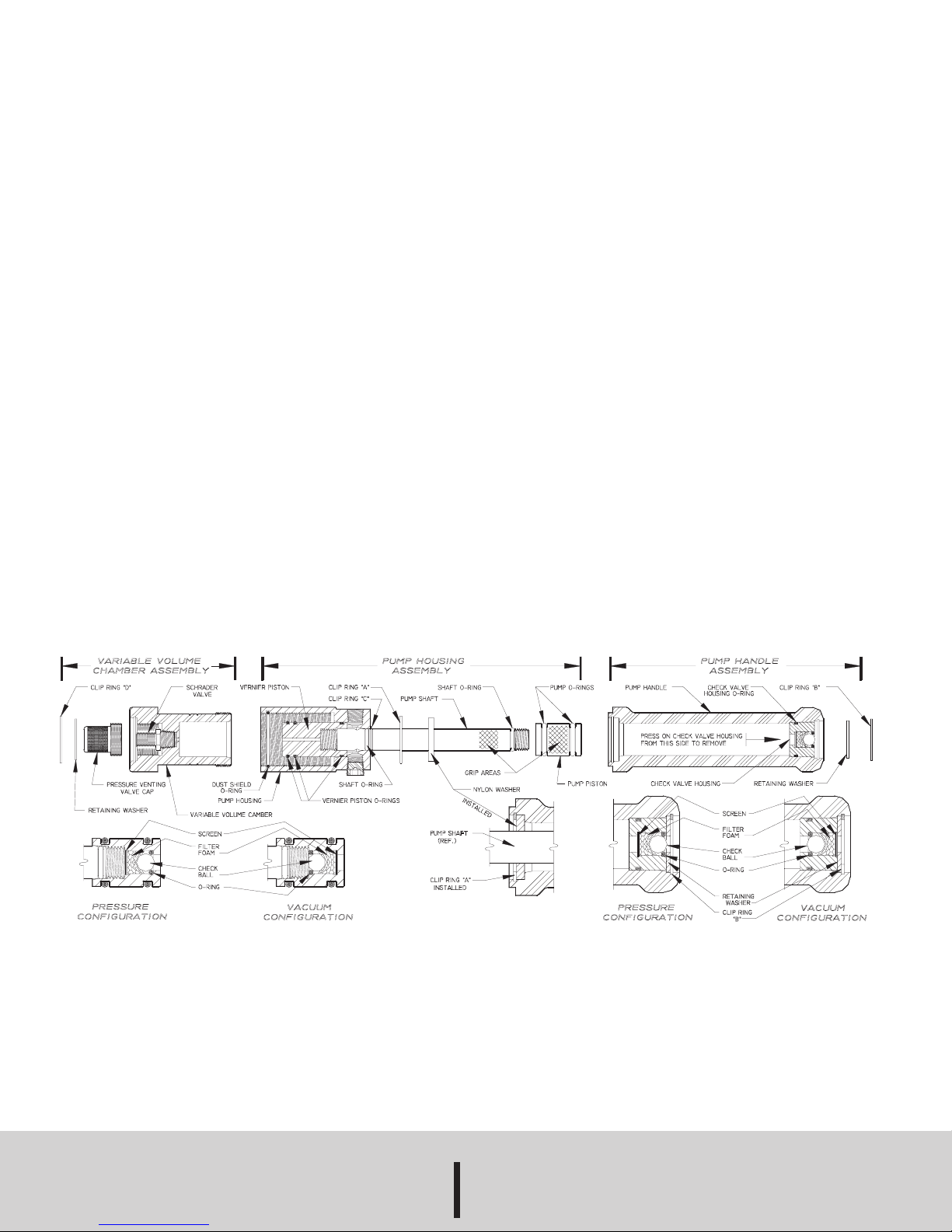

Variable Volume Chamber:

By holding the pump housing and turning the vernier knob,

the pump can be adjusted to accurate pressure or vacuum

settings. For extremely low pressure calibrations, turn the

vernier knob almost all the way in. The pump can be

adjusted in ranges less than 1˝ H2O.

NOTE: There are two warning rings on the vernier

knob column. The first is a warning and the second is

that you have gone too far. In either event, no loose

parts will fall out.

Pump Housing:

There are two 1/8˝ female NPT ports on the pump housing.

A pressure gauge can be attached to the 1/8˝ NPT port

directly or using the included 2 foot hose and 1/8˝ NPT

fitting. The other port can be plugged or a second gauge

can be connected using the CHP-KIT.

Fittings:

Series CHP Pneumatic Hand Pumps have unique fittings

and tubing. To reattach tubing to any fitting, heat the tubing

end with a heat gun or boiling water to soften it. With a

twisting action, connect the tubing to the fitting.

INSTALLATION

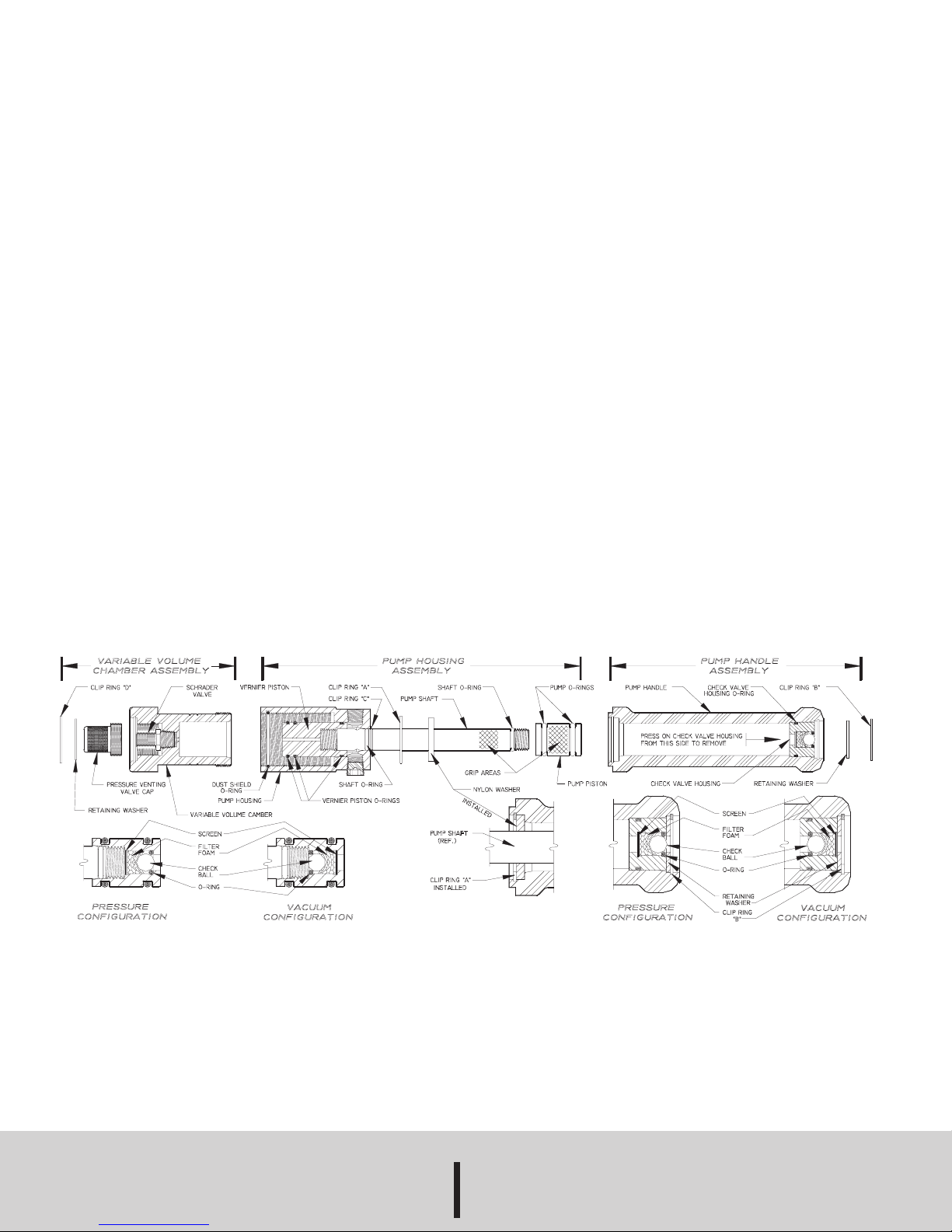

Pump Handle Assembly & Pump Piston:

To switch operation of the pump or pump piston between

vacuum and pressure, refer to Figure 2, “PUMP HANDLE

ASSEMBLY.”

PUMP CLEANING

Once the pump is disassembled, use a clean cotton cloth or

paper towel with Isopropyl Alcohol to clean off any

remaining lubricant residue. If process fluids have

contaminated the pump, please call technical support for

instructions.

MAINTENANCE

Upon final installation of the Series CHP Pneumatic Hand

Pump, no routine maintenance is required. A periodic check

of system calibration is recommended. The Series CHP is

not field serviceable and should be returned if repair is

needed (field repair should not be attempted and may void

warranty). Be sure to include a brief description of the

problem plus any relevant application notes. Contact

customer service to receive a return goods authorization

number before shipping.

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

©Copyright 2007 Dwyer Instruments, Inc. Printed in U.S.A. 12/07 FR# R6-443599-00

Figure 2

TE-CHP 12/14/07 11:23 AM Page 2