©Copyright 2008 Dwyer Instruments, Inc. Printed in U.S.A. 6/08 FR# R6-443631-00

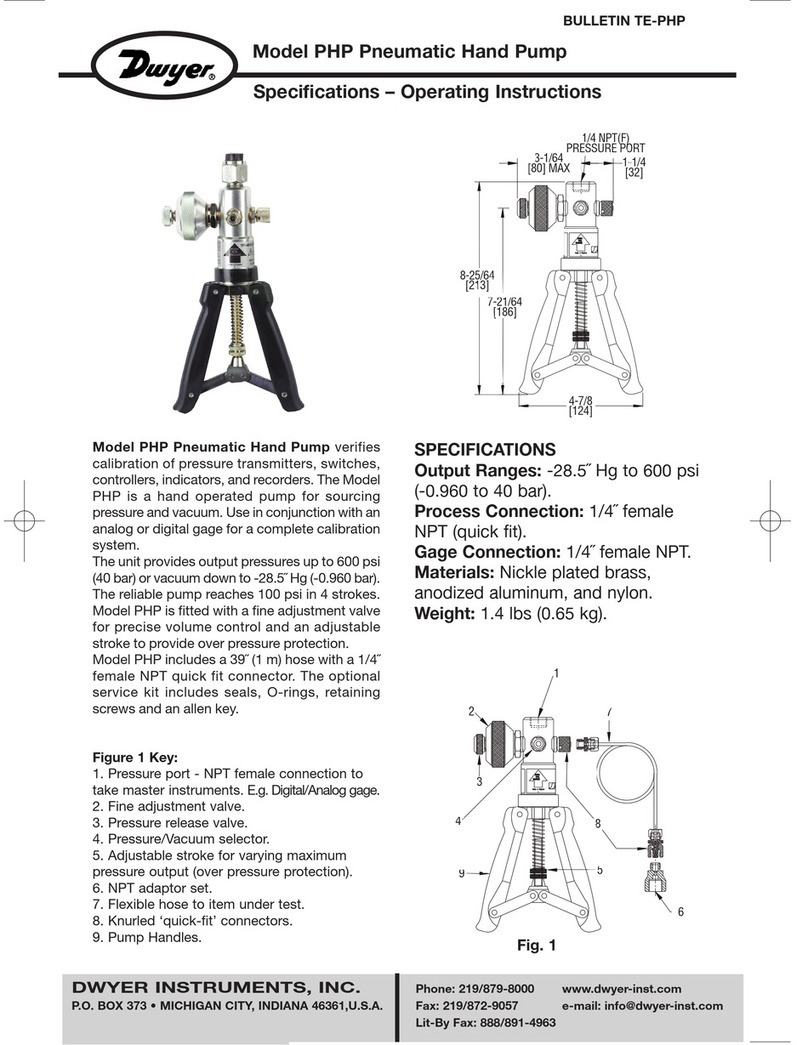

Volume Control

The pump is equipped with two knobs for fine adjustment

of the system pressure. The vent knob can be used to

slowly reduce the system pressure. The vent knob should

be closed prior to pressurizing the system by turning the

knob away from the pump housing. The Vernier knob can

be used to increase or decrease the system at a more

controlled rate. For fast relieve of the pressure, move the

pressure/vacuum pin to the opposite direction.

Over Pressure Protection

For a maximum pressure of 600 psi, the handles should be

3/4˝ apart at the closest point. To reduce the maximum

pressure, adjust the spring tension via the hex nut at the

bottom of the main shaft between the handles. The closer

the handles are to each other, the lower the amount of

pressure that will be able to be generated.

Pressure/Vacuum Selector

The pump can be used to generate pressure or vacuum

depending on the position of the pin located in the

pressure/vacuum switch. Press the pin on the side of the

pump housing according to labels for the desired operation.

For High Pressure Operation

Prior to pressurizing, back out the Vernier knob until the ring

on the Vernier shaft is showing. Pump to pressurize. Turn

the Vernier knob towards the pump housing and the

pressure should easily be able to reach 600 psi.

MAINTENANCE

Upon final installation of the Series PCHP Pneumatic

Calibration Hand Pump, no routine maintenance is required.

A periodic check of system calibration is recommended.

The Series PCHP is not field serviceable and should be

returned if repair is needed (field repair should not be

attempted and may void warranty). Be sure to include a

brief description of the problem plus any relevant

application notes. Contact customer service to receive a

return goods authorization number before shipping.

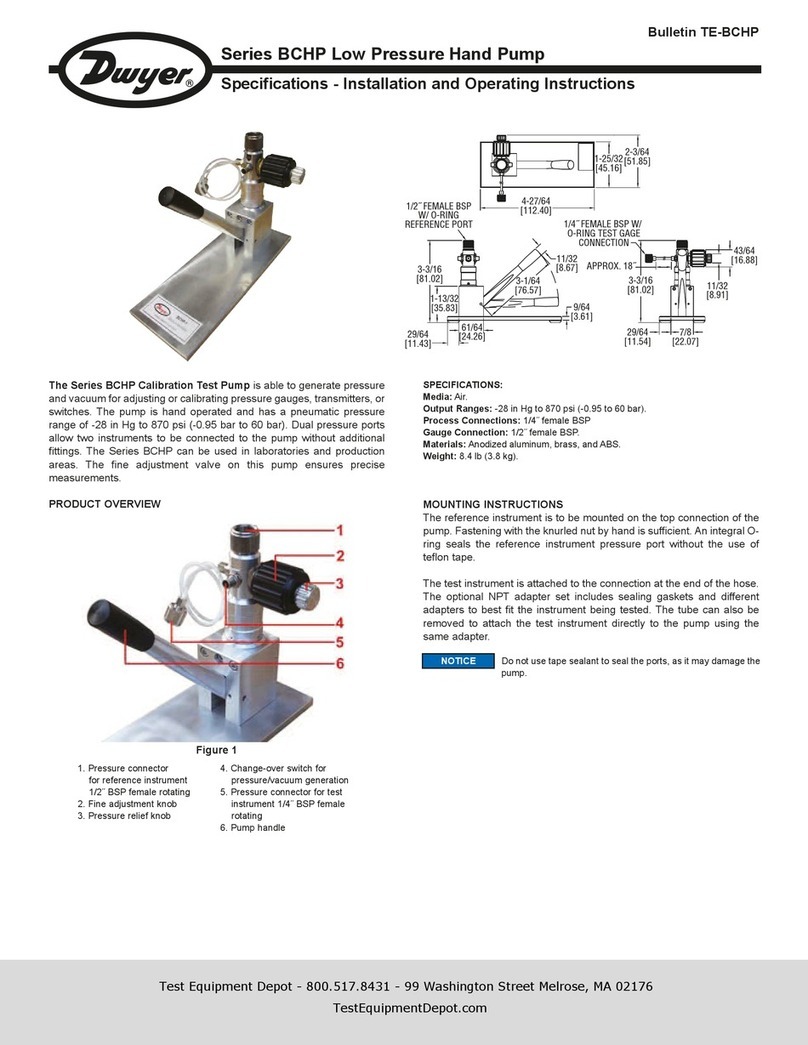

Fittings

The pump is equipped with 1/8˝ and 1/4˝ BSP ports. In

order to use NPT fittings, a NPT to BSP Parallel Thread

Adapter is required. These adapters, which are included

with the pump, have a bonded washer attached to the male

end of the adapter.

CAUTION! Do not use thread sealant paste or tape to

seal the adapters to the pump. Do not over tighten

adapters.

The pump uses a Schrader valve instead of a needle valve.

Thus, full open or closed is several turns from the end of the

travel. Over-tightening does not increase the seal.

Insure all gauges and instruments to be cali-

brated are disconnected from process pressures

before connecting the pump. The maximum

pump design pressure is 600 psig. Connection

to a pressure sources greater than 600 psig could

cause serious injury.

OPERATION

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

TOP PORT VERNIER KNOB

SIDE PORT

PRESSURE/

VACUUM

SWITCH VENT KNOB

KNOB GRIP

HANDLE

CUSHION

SPRING

COVER

SPRING

TENSION

ADJUSTER

Fig. 1

TE-PCHP:TEMPLATE 6/12/08 10:28 AM Page 2