- 7 -

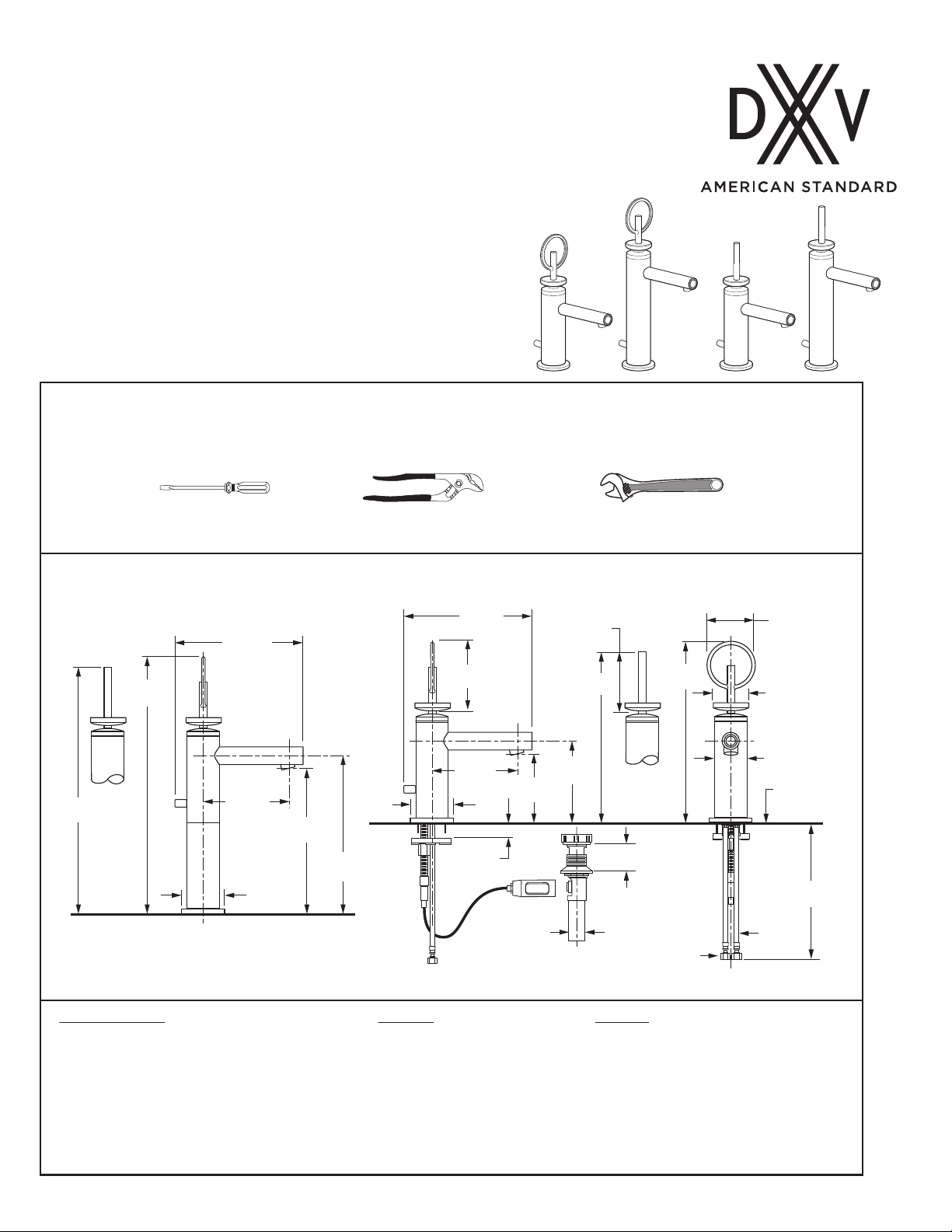

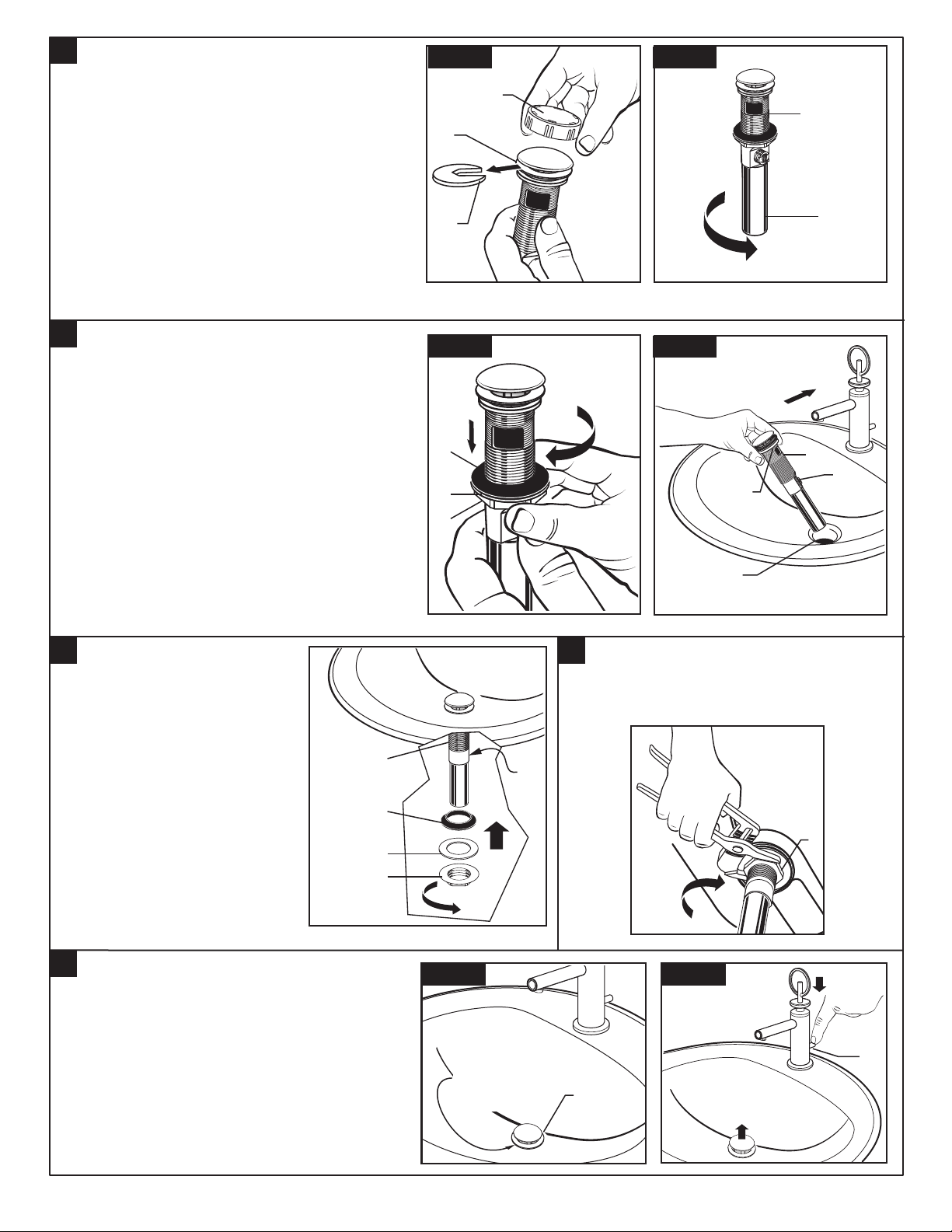

STOPPER INSTALLATION PROCEDURE

Locked Mode:

• Look at the Plastic Loop at the bottom of the Stopper and notice

that the Loop is on one side of the Stopper. Fig. G.

• To install the stopper in “Locked” mode, insert the Stopper into

the Drain so that the Plastic Loop is facing toward the rear of the

Sink. Rotate Stopper slightly if necessary so that the Stopper slides

all the way down.Fig. G.

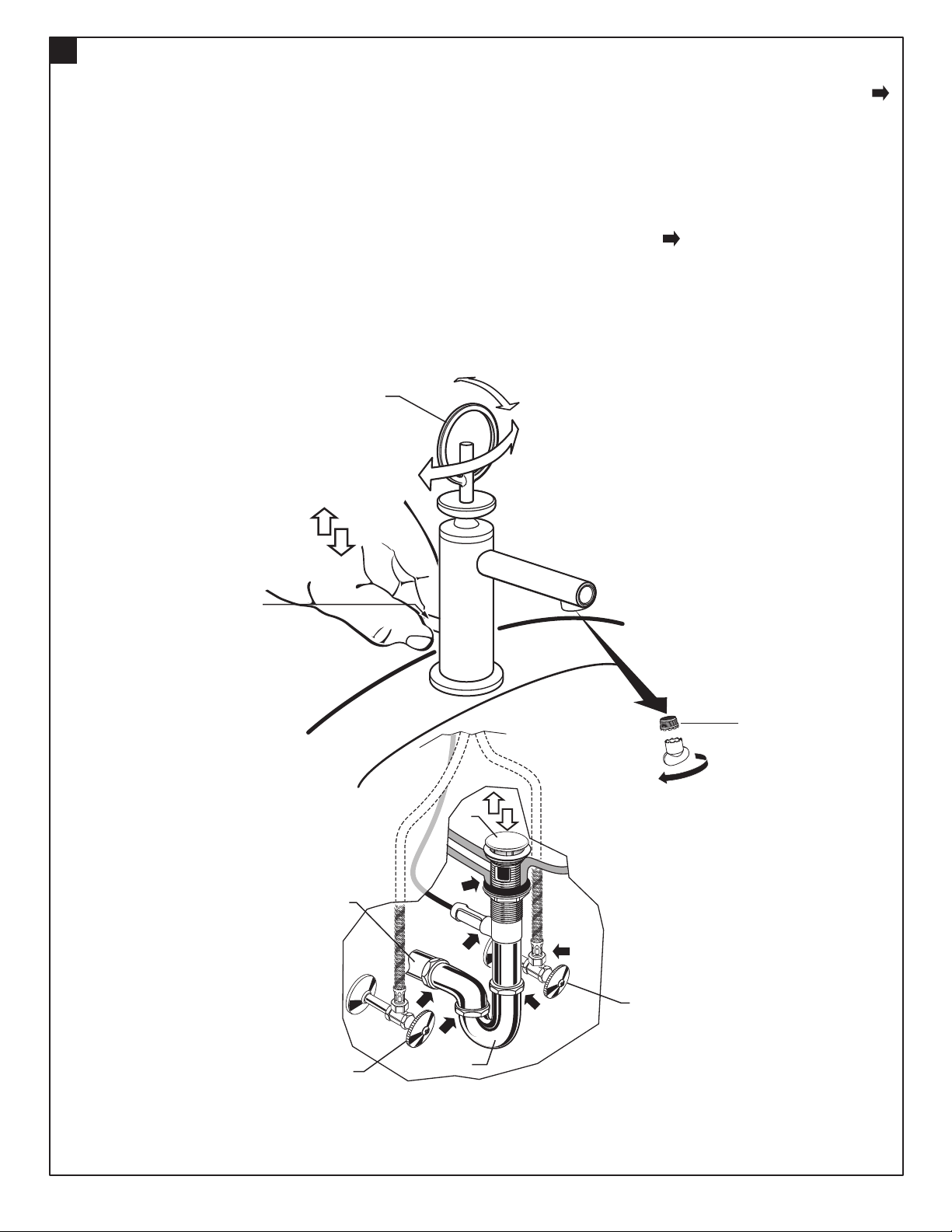

• Re-install the Cam into the Drain, rotating the Cam if necessary

to make sure it is fully inserted. Fig. J.

• Re-install the Cam Cap, making sure the guide teeth are facing

outward. If the Cam Cap does not “snap” into place, then rotate

the Cam to make sure it is fully inserted. Fig. K.

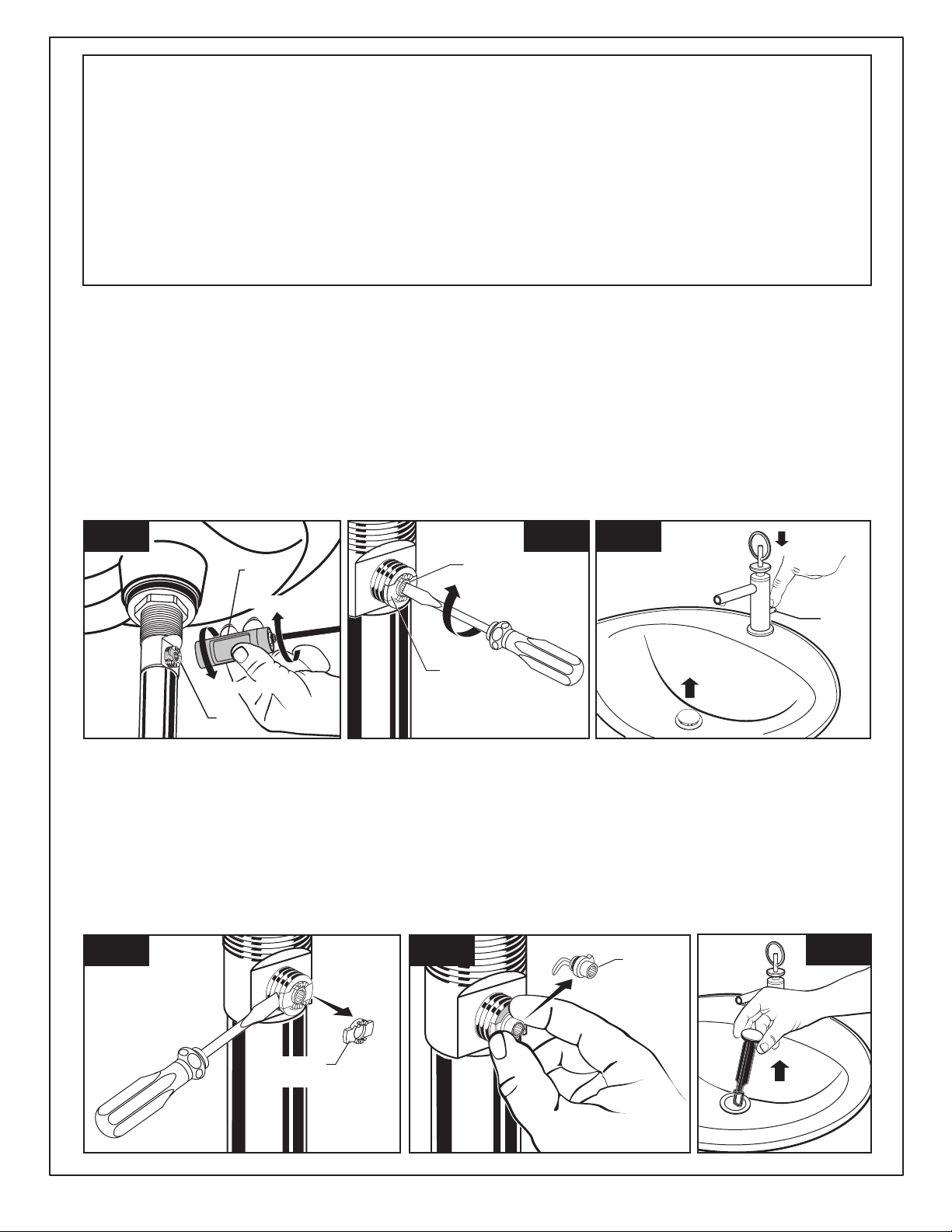

• Re-attach Cable. See “CABLE ADJUSTMENT PROCEDURE” in

Troubling Shooting Guide to complete installation. Stopper will be

in “Locked” mode and not be removable.

Unlocked Mode:

• Look at the Plastic Loop at the bottom of the Stopper and notice

that the Loop is on one side of the Stopper. Fig. H.

• To install the stopper in “Unlocked” mode, insert the Stopper into

the Drain so that the Plastic Loop is facing toward the front of the

Sink. Rotate Stopper slightly if necessary so that the Stopper slides

all the way down. Fig. H.

• Re-install the Cam into the Drain, rotating the Cam if necessary

to make sure it is fully inserted. Fig. J.

• Re-install the Cam Cap, making sure the guide teeth are facing

outward. If the Cam Cap does not “snap” into place, then rotate

the Cam to make sure it is fully inserted. Fig. K.

• Re-attach Cable. See “CABLE ADJUSTMENT PROCEDURE” in

“Troublingshooting Guide” to complete installation. Stopper will be

in “Unlocked” mode and removable.

Fig. J. Fig. K.

INSTALL

CAM CAP

CAM

INSTALL CAM

The Stopper can be installed two ways, “Locked” Mode (Stopper cannot be removed)

or “Unlock” Mode (Stopper is removable).

Unlocked Mode

Locked Mode

(Vandal Proof)

LOOP TOWARD

REAR OF SINK

LOOP TOWARD

FRONT OF SINK

DRAIN

DRAIN

Fig. H.

Fig. G.

M965530 Rev. 1.3