INSTRUCTIONS MANUAL – BR-BM

File: 4700367205_ENG_NO.doc Page 3 / 25

SUMMARY

GENERAL SAFETY RULES...............................................................................................4

Machines submitted........................................................................................................................................4

Symbols...........................................................................................................................................................4

Important rules for your safety ........................................................................................................................4

Safety equipment ............................................................................................................................................4

Working area...................................................................................................................................................4

Power supply...................................................................................................................................................5

Starting the machine .......................................................................................................................................5

Operation.........................................................................................................................................................5

Maintenance....................................................................................................................................................5

Be alert............................................................................................................................................................5

GENERAL ...........................................................................................................................6

DESIGN...............................................................................................................................6

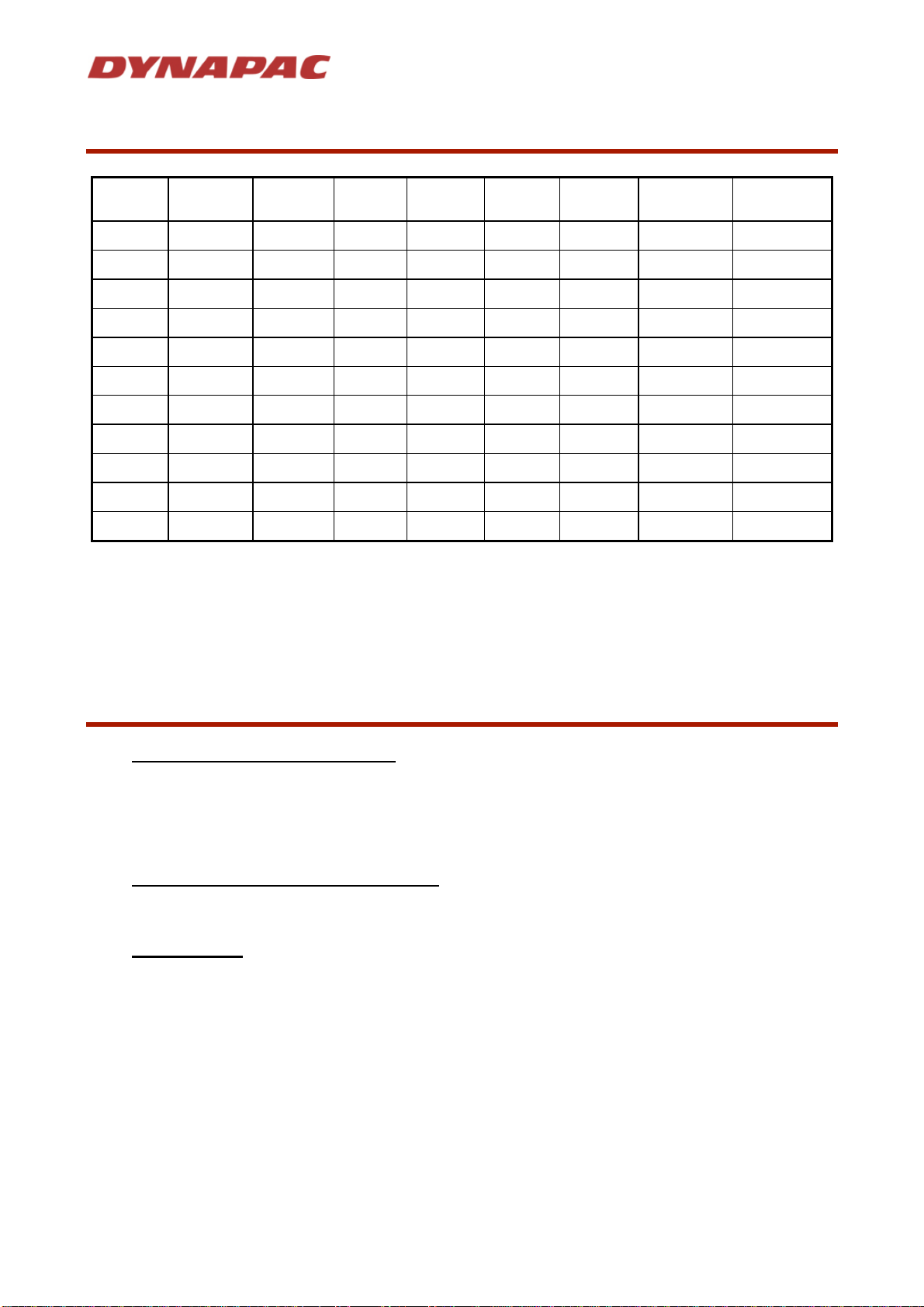

TECHNICAL DATA .............................................................................................................7

OPERATING INSTRUCTIONS............................................................................................7

ELECTRIC VIBRATOR ER 505.....................................................................................................................7

PETROL ENGINE VIBRATOR BE 10.............................................................................................................7

SCREEDING...................................................................................................................................................7

MAINTENANCE ..................................................................................................................8

WORKSHOP INSTRUCTIONS ...........................................................................................8

TENSIONNING THE BEAM............................................................................................................................8

ORDER NUMBERS.............................................................................................................9

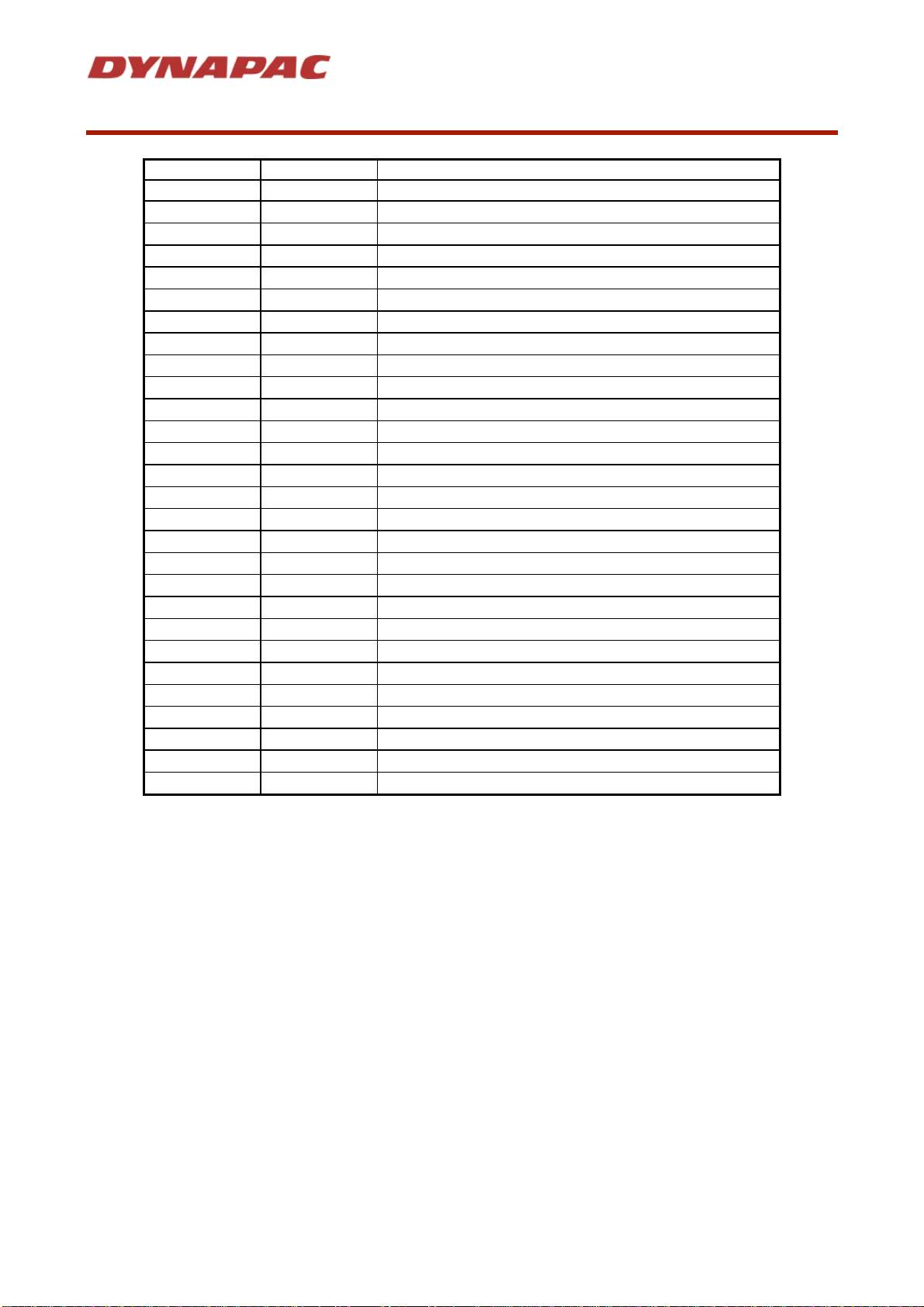

SPARE PARTS CATALOGUE..........................................................................................11