DYNISCO PG500 Series

77

77

7

77

77

7

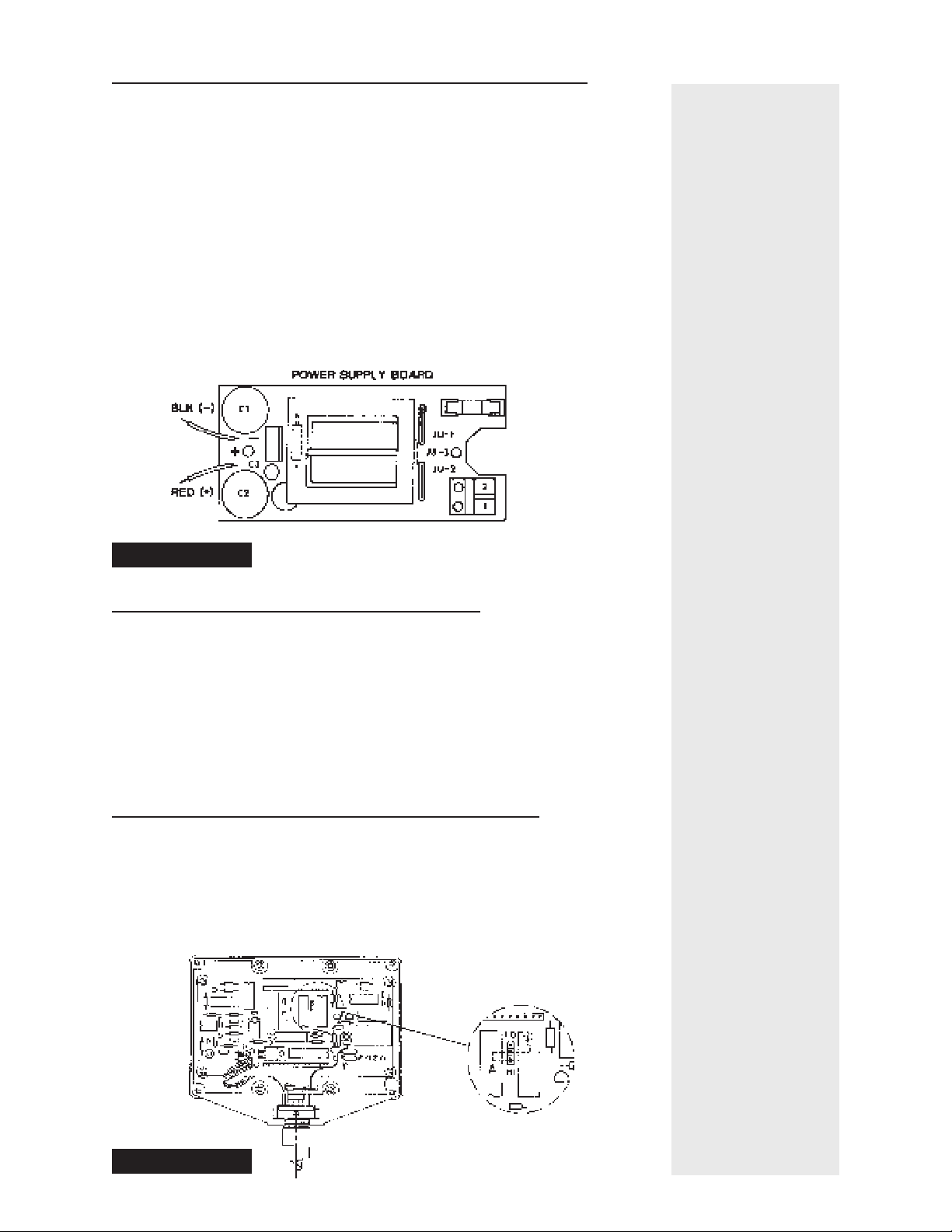

4. INTEGRAL POWER SUPPLY

(P/N 496309 OR OPTION G115)

If your gauge is already equipped with the 12 VDC power supply

(Option G115), the wiring is done as follows:

1. Remove the power supply cover and install strain relief.

2. Connect the 115 or 230 VAC power supply leads to Terminals 1

and 2 on the terminals 1 and 2 on the terminal block at the end of

the power supply printed circuit board and feed these through the

strain relief. (See Fig. 6)

3. If the gauge is equipped with an alarm, attach the appropriate leads

to the five terminals on the terminal strip on the gauge printed

circuit board and feed these through the strain relief.

4. Replace the power supply cover and adjust the wires for service

loop. (See Fig.8).

If you are adding a power supply to an existing gauge, the wiring is

done as follows:

1. Remove from the gauge body the plate holding the strain relief

assembly by removing four screws. Detach the two 12 VDC leads

going to the terminals on the short terminal block on the gauge

printed circuit board and remove them from the strain relief

assembly. 2. Remove power supply cover from base and install

strain relief.

3. Attach the power supply base to the gauge body using the four

tapped inserts and the four screws supplied.

4. Install a black (-) wire from the power supply assembly to Terminal

1 on the short terminal block on the gauge printed circuit board.

Install a red (+) wire from the power supply board to Terminal 2

on the gauge printed circuit board. (Figs. 8 & 9)

5. If the gauge is equipped with an alarm, attach the appropriate leads

to the five terminals on the terminal strip on the gauge printed

circuit board and feed these through the strain relief.

6. Connect the 115 or 230 VAC power supply leads to Terminal 1

and 2 on the terminal block at the end of the power supply

printed circuit board and feed these through the strain relief. (Figs.

8 & 9)

7. Replace the power supply cover, adjust the wire for service loop.

(Fig. 8)

8. Replacement fuse Dynisco P/N 927017, Littlefuse P/N 217.063

or equivalent.