Technical info.

Service manual

04

When DC25 is switched on in the upright position, the brushbar motor is off. Tilting the machine into

normal vacuuming mode will automatically operate the upright switch, turning the brushbar motor on.

The brushbar motor can be switched off using the brushbar switch.

The vacuum motor of DC25 is fitted with a heat sensitive Thermal Cut-Out (TCO). This will shut the

motor down for up to 60 minutes if it reaches a temperature >96 degrees celcius. Excessive

temperatures within the motor are usually caused by machine/filter blockages.

The switch housing is fitted with a TCO reset switch that will shut the brushbar motor off if it is put

under an excessive load (blocked/seized brushbar etc.). The cause of the shut down should be cleared

and the TCO reset by pressing the brushbar switch button.

If the cause of the brushbar motor cut-out is not rectified the TCO will repeatedly reactivate, preventing

the brushbar from turning.

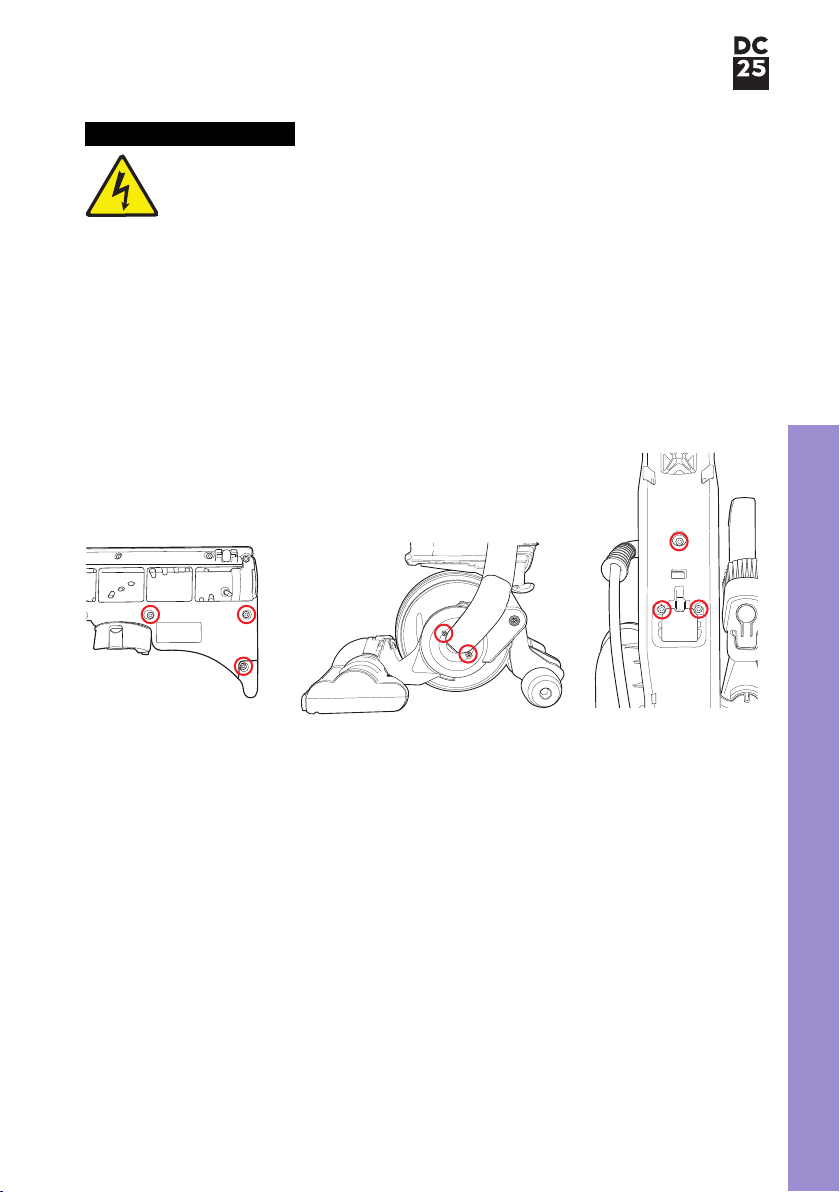

Electrical fault diaignosis

Note: all ‘connection’ numbers and ‘continuity’ checks refer to the illustration and table on page 3.

No machine power (vac motor and brushbar motor off)

1) Check for damage/electrical failure to the plug, fuse and powercord.

2) Check for a loose connection at points 1, 2 and 7.

3) Check the mechanical actuation of the on/off switch.

4) Test the resistance of the powercord, fuse (UK only), on/off switch and the neutral wire of the internal

cable (points 7 to 11).

No power to the vac motor (brushbar motor on in tilt position)

1) Check for a loose connection at points 8, 9, 10 and 11.

2) Test the resistance of the motor cable assembly (points 8 to 9 and 10 to 11) and across the vac

motor (points 9 to 10).

3) Check the vac motor brushes, windings, commutator etc. for signs of wear or damage.

No power to the brushbar motor (vac motor on)

1) Ensure the TCO reset button has been pressed.

2) Check for a loose connection at points 3, 4, 5, 6, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22,

23 and 24.

3) Check the mechanical actuation of the brushbar switch and upright switch.

4) Check the brushbar motor and PCB assembly for signs of damage/wear.

5) Test the resistance of the brushbar switch (points 3-4), the switch/TCB cable (points 4 to 5), the

internal cable (red wire only points 6-13), the upright switch (points 13-14), the yoke loom (points

12 to 16 and 14 to 15) and the cleaner head assembly (wires from the plug to the PCB only, points

17 to 19 and 18 to 20).

If no faults are found replace the cleaner head assembly.

Brushbar motor on in upright position (switches off with brushbar switch)

1) Check the mechanical actuation of the upright switch. Ensure the micro switch isn’t jamming or sticking.

Brushbar switch does not switch brushbar motor off in tilt position

1) Check for correct location of the brushbar reset arm (see item 121, page 47).

2) Check the mechanical actuation of the brushbar switch.

3) Test the resistance of the brushbar switch (points 3-4).

Electrical fault diagnosis

Wire colours may vary between territories.