3) Place the vehicle in S-mode and drive it as an automatic. You will hear 1 beep, indicating

successful engagement. Additionally, RED LED will light.

•If the vehicle is initially stopped when ShiftSense Pro is engaged, you should notice the

gear selection immediately drops to S2, which is the lowest S selection provided by the

ShiftSense™Pro *(see notes below for more detail). If at higher speeds, the device will

engage into the appropriate S-gear for the speed which you are traveling.

•The driver is not required to manipulate the shift-lever at all after engagement as the

ShiftSense™Pro will perform all shifts automatically at the optimum combination of

speed, throttle position, accelerator position, and RPM as programmed into the device.

Operation Notes:

•The conditions for ShiftSense Pro engagement are:

oVehicle speed must be less than 65 miles per hour.

oInitial communication must be established after engine-start and the two-

beeps heard.

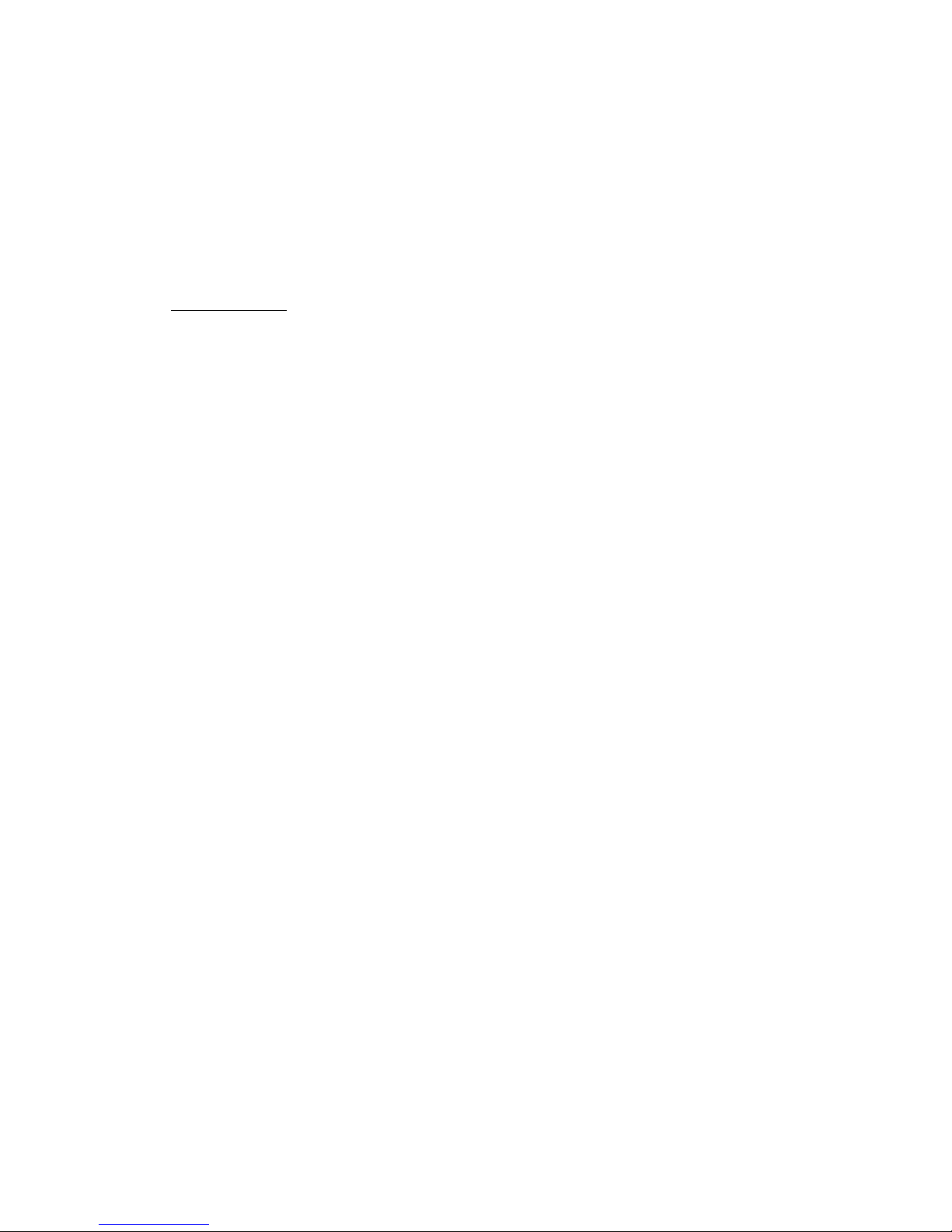

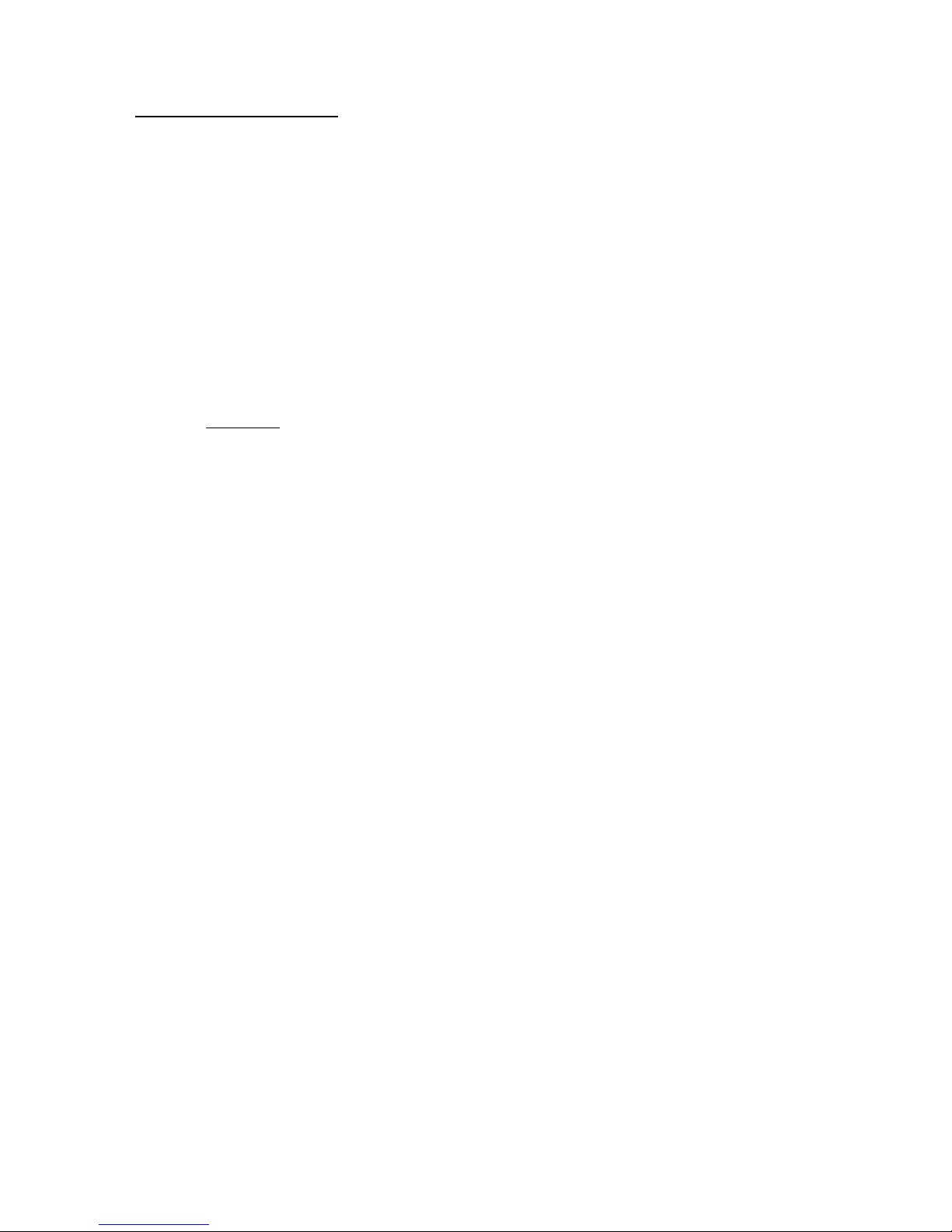

•If the driver prefers manual OEM functionality of the Sequential shift mode, the

automatic control can be cancelled at any time by the driver making a manual shift

(S+/S-) with the lever. If the control is cancelled, it will provide 3 beeps. At this point,

the vehicle will remain in sequential ‘S-mode’in the currently selected gear. The

operator can then continue driving with manual Sequential-shift mode, but the driver

is now responsible for making the shifts as needed and the ShiftSense™Pro will remain

on standby. Re-engagement can be accomplished by moving the lever to drive “D”,

then back to Sequential “S”.

•The ShiftSense™device operates in all normal driving conditions, including cruise

control and 4wd. It does not operate while in 4WD low-range and will cancel if

attempted, allowing the driver to use S-mode manually.

•*The lowest commanded gear selection provided by ShiftSense™Pro is S2. Even

though the dash display may indicate S2, the vehicle will still use 1st gear when starting

out from stop. Shifts between 1 and 2 are heavily influenced by torque-convertor

operation, which the OEM mapping handles well so it is left as-is.

•The device contains compensation for cold engine-temp operation. It will

automatically reduce the shift map based on the current engine temperature. This is

designed to coincide with the Toyota torque-convertor on this vehicle which will not

lock-up at engine-coolant temp less than 158 F. The driver may notice the shifts

provided by ShiftSense™Pro will occur at slightly lower speed/rpm for the first few

miles until the engine warms up.

•The ShiftSense™Pro selects the appropriate S-mode gear based on its programming.

In some instances, the vehicle may perform downshifts on its own which were not

specifically commanded by the ShiftSense™Pro. This is normal, and occurs due to

some small overlaps in the OEM shift-map and the ShiftSense™Pro shift-map at high

throttle positions. Additionally, to avoid harshness in downshifting at low speed, the

ShiftSense™Pro commands its downshift from S3 to S2 at a slowing speed of

approximately 5 mph. Therefore it is normal to feel the OEM map make downshifts to

2nd at slightly higher speeds (6-25mph) even if the ShiftSense™Pro commanded gear

remains indicated as S3. If slowing the vehicle to stop, the ShiftSense™Pro will always

perform the appropriate downshift to S2 once speed decreases below 5 mph.

•To provide optimum engine-braking, the ShiftSense™Pro’s programming prevents any

upshifting while the accelerator pedal is totally released.

•DO NOT USE SHIFTSENSE PRO IN PARALLEL WITH OTHER FAST-POLLING OBD DEVICES

THROUGH AN OBD SPLITTER. Other fast-polling devices such as ELM327 (torque app

and OBD-fusion) can compete for bandwidth over the OBD communication

network. This could affect performance of the ShiftSense Pro.