E-Mon Class 2000 User manual

62-0389-03

INSTALLATION INSTRUCTIONS

Class 2000 Meter

KWH & KWH/DEMAND METER

E-Mon

850 Town Center Drive

Langhome, PA 19047

(800)334-3666

www.emon.com

CLASS 2000 METER

62-0389-03 2

Dear Valued Customer,

We are pleased that you chose to buy one of our products, and want you to be just as

pleased with owning it. Before installing your new E-Mon product, please read the

information on the following pages carefully.

We believe that you will find the E-Mon D-Mon meters easy to install and to use for

monitoring and evaluating your electrical usage.

To be sure that you are 100% satisfied with your products, we provide toll-free

technical and sales support Monday through Friday, 8:00 am to 7:30 pm, EST: (800)

If you have questions, we can handle them quickly and effectively with a telephone call.

Please let us try to help you BEFORE you remove your meter. And to help us help you,

we ask that you have all relevant information on hand when you call (model or part

numbers, nature of difficulty, etc.)

Be sure to forward this manual to the owner after installation is complete, so that they

may use it as a reference guide when reading the E-Mon D-Mon meter.

Thank you.

CLASS 2000 METER

3 62-0389-03

TABLE OF CONTENTS

Section 1.0 Pre-Installation Information 4

Section 2.0 Safety Label Definitions and Information 6

Section 3.0 Precautionary and Safety Information 7

Section 4.0 Meter Installation 8

Section 4.1 Mounting the Meter 8

Section 4.2 Main Power Board Connections 8

Section 4.3 Current Sensor Installation & Wiring 11

Section 4.4 MAINS Line Voltage & Current Sensor Wiring

Diagrams

14

Section 4.5 Installation Overview 16

Section 4.6 Check Polarity of the Current Sensor 16

Section 5.0 Monitoring Multiple Loads with One Meter 18

Section 6.0 KWh Meter Features & Functions 20

Section 6.1 KWh Meter Display Features 20

Section 6.2 How to Read the kWh Meter 22

Section 6.3 KWh Meter Hardware Functions 22

Section 6.4 Class 1000 and Class 2000 Pulse Output Removable

Two-Screw Terminal Plug

22

Section 7.0 KWh/Demand Meter Features & Functions* 24

Section 7.1 KWh/Demand Meter Display Functions 24

Section 7.2 How to Read the kWh/Demand Meter 25

Section 7.3 Demand Display Set-Up 26

Section 7.4 Demand Reset 28

Section 8.0 Preventative/Scheduled Maintenance 29

Section 9.0 Lithium Battery Replacement Instructions 30

Section 10.0 Troubleshooting Guide 32

Section 10.1 Line Voltage Diagnostics 33

Section 10.2 Current Sensor Diagnostics 34

Section 11.0 High Voltage Metering 35

Section 12.0 Frequently Asked Questions 38

Section 13.0 Meter Technical Specifications 40

Section 14.0 Meter Limited Warranty 43

* Applies to meters equipped with the Demand option.

CLASS 2000 METER

62-0389-03 4

1.0 PRE-INSTALLATION INFORMATION

The E-Mon D-Mon® Class 2000 kWh/Demand meter is a 3-element meter used to

monitor electric power usage of individual loads after the utility meter. Installation must

only be performed by qualified personnel and in accordance with these instructions

and all applicable local and national electrical codes. E-Mon or its representatives

assume no responsibility for damages or injury resulting from the improper installation

of this meter.

Meters are supplied in a UL Type 1 steel enclosure appropriate for indoor installation

where it will not be affected by the elements, such as moisture and extreme

temperatures.

Units designated by the “R” suffix on the model number have an extended

environmental operating range and are enclosed in a NEMA 4X enclosure to

accommodate outdoor environments. Verify the input voltage rating and configuration

on the meter label to ensure it is suitable for the intended electrical services. Class

2000 meters labeled for 120/208V service MUST NOT be installed on service feeds of

277/480V and vice versa.

Verify the current sensors are sized suitably for the load to be monitored. Compare the

color of the arrows on the current sensors to the chart below to confirm the correct

current sensor is being used.

Sensor Arrow Color Code Sensor Rating

Brown 100 Amp

Red 200 Amp

Yellow 400 Amp

Black 800 Amp

Blue 1600 Amp

White/Black 3200 Amp

CLASS 2000 METER

5 62-0389-03

CAUTION

Internal circuit card components are extremely sensitive to electrostatic

discharge. Prior to handling or touching internal circuitry, discharge any static

buildup on your person. To discharge yourself, touch a grounded metal object

such as conduit or an earth grounded metal enclosure.

WARNING

Use of this instrument, Class 2000, in a manner inconsistent with this manual

or not specified by the manufacturer in writing, can cause permanent damage

to the unit and/or serious injury to the operator. The protection and safety

features provided by this equipment may become impaired or otherwise

compromised.

NOTE: If any trouble arises during installation or functional verification operations, do

not immediately remove unit. Before removing the unit, contact E-Mon’s tech-

nical support department at (800) 334-3666. E-Mon’s technical department

will assist you in detailed troubleshooting of the Class 2000 installation.

1.1 Internal Electronic Assemblies

The unit is comprised of a Main Power Board, Display Board and Keyboard. All circuit

cards are mounted inside a UL Type 1 (standard) or NEMA 4X (optional) enclosure.

Fig. 1. Power Supply Board and Display Board.

NOTE: Units are supplied in a UL Type 1 metal enclosure suitable for indoor applica-

tions only. Units supplied in the optional NEMA 4X fiberglass enclosure are

suitable for either indoor or outdoor applications, within the defined specifica-

tions. Refer to Section 12.0 for a definition of suitable environmental condi-

tions for indoor and outdoor units.

M33177

MAIN POWER

BOARD

DISPLAY AND

KEYBOARD

CLASS 2000 METER

62-0389-03 6

1.1.1 Main Power Board

Connections to this board include the MAINS Input Voltage, Current Sensors, external

IDR interface and Isolated Pulse Output. The MAINS input terminals are covered with

a protective shield for safety purposes. The current sensor assemblies interface to

three header connectors, labeled A, B, and C along with conductor color indication.

Each header connector input corresponds to an input voltage phase, so care must be

taken to ensure each current sensor is connected to the correct input header.

Fig. 2. Standard Configuration.

1.1.2 Display Board

The display connects to the main power board via a flex-ribbon cable and is mounted

on the inside of the enclosure door. The LCD readout indicates the cumulative kWh

and instantaneous kW value on kWh meters. The LCD readout indicates cumulative

kWh, peak demand and instantaneous kW values on kWh/ Demand meters).

2.0 SAFETY LABEL DEFINITIONS AND

INFORMATION

The Green Class meter may contain one or more of the following labels. Operator(s)

should familiarize themselves with the meaning of each label to minimize risk.

The presence of this label is a cautionary indicator identifying a

danger risk. The manual should be consulted prior to proceeding.

The presence of this label indicates an electrical shock hazard exists

in the location or area where the label is placed. Prior to proceeding,

the MAINS power must be disconnected and the manual consulted for

safety information.

M33178

TB1 TB2 TB3 TB4

CLASS 2000 METER

7 62-0389-03

3.0 PRECAUTIONARY AND SAFETY

INFORMATION

CAUTION

Internal circuit card components are extremely sensitive to electrostatic

discharge. Be careful not to touch internal circuitry prior to discharging any

static buildup on your person. To discharge yourself, touch a grounded metal

object such as conduit or an earth-grounded metal enclosure.

WARNING

High voltages present on main PCB terminal block TB1 screw terminals. Risk

of serious injury and/or electrical shock exists. Prior to performing any wiring

operations, review all contents of the user manual and de-energize the MAINS

power switch. Only qualified personnel should perform installation wiring.

Installation wiring must comply with all local and national electrical codes.

WARNING

Failure to ground the enclosure creates a possible shock hazard. Do not

operate the Class 2000 meter without a protective earth wire attached securely

to the PE terminal screw. After installing protective earth wiring, secure the

screw tightly (7in-lb torque.)

WARNING

NEVER open front panel of unit while unit has MAINS power applied. Failure to

comply can increase the risk of serious injury and/or electrical shock.

CLASS 2000 METER

62-0389-03 8

4.0 METER INSTALLATION

4.1 Mounting the Meter

Using the appropriate sized mounting hardware, fasten the Class 2000 meter

enclosure to the selected mounting surface. The four mounting holes are centered

6.75” H x 4” W. The mounting hole spacing is identical for either the UL Type 1 or

NEMA 4X enclosure.

NOTE: Only the NEMA 4X enclosed unit is suitable for outdoor environmental condi-

tions. Units housed in UL Type 1 enclosures must only be installed in indoor

environments where it will not be affected by the elements, such as moisture

and extreme temperatures.

Fig. 3. Enclosure Dimensions.

4.2 Main Power Board Connections

1. Install a temporary ground for ESD (Electrostatic Discharge) protection. With all

circuits de-energized, connect a temporary protective earth ground connection

for ESD protection. Prior to performing any unit wiring, be sure to discharge any

static on your person.

2. Install the Class 2000 Protective Earth Ground. Connect an earth ground wire to

the Class 2000 protective earth ground terminal screw located on the right side

of the line voltage terminal block. After installing the protective earth ground wire,

securely fasten the protective earth ground screw.

3 (76)

7-1/2

(191)

M33627

6 (152)

4 (102)

6-3/4

(171)

CLASS 2000 METER

9 62-0389-03

WARNING

Failure to attach the protective earth ground wire securely to the enclosure

creates a potential shock hazard. Do not operate the Class 2000 meter without

a protective earth ground connection securely installed.

3. Wire Entry.

a. Two openings exist on the unit enclosure, one for 1/2” conduit and one for 3/

4” conduit. The 3/4” conduit opening located on the bottom of the enclosure

is used to bring in MAINS Power (voltage lines to power meter) and current

sensor wiring. The 1/2” conduit opening located on the top of the enclosure

is used to interface low voltage signals, such as the IDR interface and iso-

lated pulse output. (Outdoor enclosures equipped with one 3/4” conduit

opening on bottom of enclosure only.)

b. Route the appropriate cabling to and through the respective enclosure open-

ing. The conduit and fittings interfacing the enclosure entrances must be UL

listed and properly sized to the enclosure port diameter, The interfacing fit-

ting must use a gasket seal ring to interface between the conduit fitting and

the enclosure entry point. After installing the conduit fitting and conduit, verify

that the conduit fittings are aligned properly to their respective enclosure

entrance ports and tightened securely to prevent moisture entry. VERIFY

that each conduit slip nut is securely tightened to its respective conduit fit-

ting.

c. Outdoor applications require the use of the optional 4X enclosure. The same

principles outlined for indoor meter installations as defined in the aforemen-

tioned paragraph carry over and apply to outdoor installations with one

exception. This exception is that the conduit and fittings for outdoor installa-

tions require an outdoor material rating and approval for 4X applications.

4. Unit MAINS Wiring (Voltage Wiring Connections)

a. Remove the shield located over the phase A,B and C screw terminals on the

main power board. This shield can be removed by pulling back on the latch

on the right side of the shield and lifting up on the front. Wire each connec-

tion to the terminal block with stranded wire 14-12 AWG, rated at 600 VAC.

b. Strip back all wire insulation to expose between 1/4” and 3/8” of the copper

conductors. Gently twist each wire to prevent fraying. Insert the conductors

into their respective terminal block position and tighten down the terminal

block screw to securely fasten the conductor. The terminal block is clearly

labeled PHASE A, PHASE B, PHASE C and NEUTRAL.

c. Connect the NEUTRAL wire to the appropriate terminal block position.

NOTE: For Delta MAINS input wiring, DO NOT connect the NEUTRAL wire. Remove

the terminal block screw for this position.

CLASS 2000 METER

62-0389-03 10

d. Connect the AC mains power wires (Phase A, Phase B and Phase C) to their

respective positions as labeled on terminal block.Tighten the screws to 7 in-

lb of torque.

e. After all conductors are connected to their respective terminal block positions

and tightened down, verify that each terminal block screw is securely fas-

tened by gently tugging on each conductor. Verify no conductor wires are

frayed or are shorting to adjacent terminal block positions.

5. External Switch Mechanism/In-Line Fuse Installation

a. To ensure a safe installation, the Class 2000 meter requires an external

switch mechanism, such as a circuit breaker, be installed on the Class 2000

MAINS input wiring. The switch mechanism must be installed in close prox-

imity to the meter and easily reachable for the operator. This device must

also be marked as the disconnecting device for the Class 2000 meter.

b. Install 1/10 Amp Slow Activation in line fuses with the suitable voltage rating

for each conductor phase at the MAINS input to the meter. The fuses must

be labeled to indicate voltage and current rating as well as element charac-

teristics. The fuse element must be slow activating type.

6. Once the MAINS wiring is complete, replace the clear Lexan protective shield

over terminal block TB1 and close the enclosure front panel. Secure the enclo-

sure cover using the locking mechanism. Activate the external circuit breaker or

equivalent switch to apply AC MAINS power to the unit.

7. The Class 2000 meter display should turn on and indicate total kWh accumula-

tion reading.

NOTE: On demand meters the unit display, clock and other critical configuration

parameters will be reset once the unit installation and wiring is complete.

8. Using an AC Voltmeter, verify the input voltage readings are within the limits

specified below.

9. Remove power from the unit by de-energizing the external switch.

NOTE: For 3-Wire systems, the voltages are measured Phase to Phase. On 4-Wire

systems the voltages are measured Phase to Neutral.

Meter Input Voltage

Configuration Nominal Voltage Limits (+/- 10%)

120/208V, 3 Ph, 4 Wire 120 VAC (L-N) 108 to 132 VAC

277/480V, 3 Ph, 4 Wire 277 VAC (L-N) 249 to 305 VAC

240V, 3 Ph, 3 Wire 240 VAC (L-L) 216 to 264 VAC

480V, 3 Ph, 3 Wire 480 VAC (L-L) 432 to 528 VAC

347/600V, 3 Ph, 4 Wire

(WYE Only)

347 VAC (L-N) 540 to 660 VAC

CLASS 2000 METER

11 62-0389-03

4.3 Current Sensor Installation & Wiring

Once the AC voltages have been confirmed to be within acceptable limits, you are

ready to install the current sensors. The MAIN power board contains three header

connectors located at the bottom right of the board. The connectors are labeled A, B,

and C along with conductor color indication. This format must be followed in order for

the meter to function correctly.

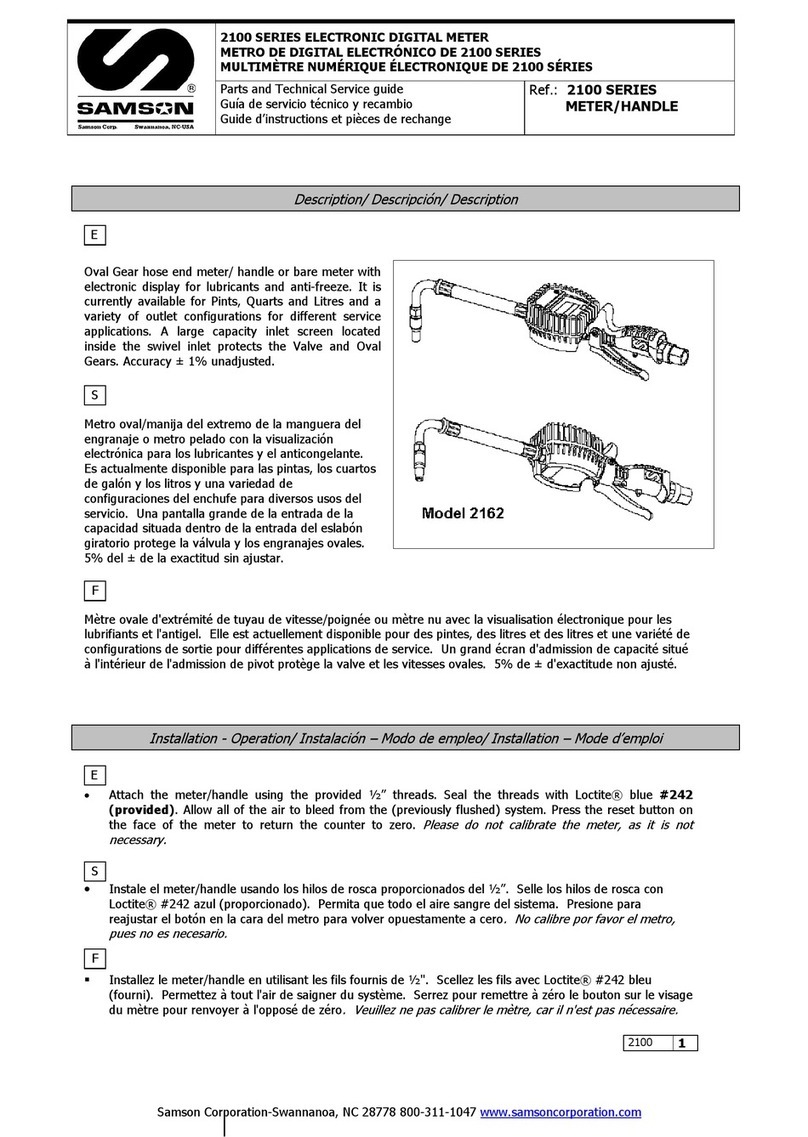

The Class 2000 meter will be used with one of two basic types of current sensors:

a. Split-Core Current Sensor: This sensor opens so that it can be attached

around the circuit conductor being monitored without interrupting power.

Unless otherwise

specified, all Class 2000 meters are supplied with this sensor type.

b. Solid-Core Current Sensor: This sensor does not open and requires the

monitored conductor be removed from the circuit to install the current sensor.

This type is only supplied when specified at time of order.

NOTE: The unit serial label specifies if the unit is set up for split or solid core current

sensors. See ordering information for details.

Both types of current sensors output a 0-2 VAC signal proportional to the current being

measured.

The current sensors must be matched with the voltage phases. The A phase sensor

must be monitoring the same phase as the A phase voltage. B & C phase sensors

must also monitor the same phase as their respective voltage inputs.

CLASS 2000 METER

62-0389-03 12

4.3.1 Installing the Split-Core Current Sensor Assembly

Each phase being monitored will require one two-piece current sensor assembly.

Therefore, a three-phase meter will require three (3) assemblies. Open the two-piece

current sensor assembly by releasing the nylon clamp using a flat head screwdriver.

Fig. 4. Split-Core Current Sensor Assembly.

1. Reassemble the current sensor assembly around the conductor(s) to be moni-

tored. Ensure the current sensor halves marked “Load” are both facing the load

side of the conductor. The colored arrow will be on the source side of the con-

ductor being monitored and MUST be pointed in a clockwise direction around

the conductor being monitored. Tighten the nylon clamp to complete the assem-

bly.

Fig. 5. Arrow On The Current Sensor Assembly.

IMPORTANT:

When looking from the source side of the conductor(s) being monitored, you

should see the arrow on the current sensor assembly. The arrow should be

pointing in a clockwise direction around the conductor(s) being monitored. If

the arrow is not positioned on the source side, inaccurate readings will result.

M33213

LOAD

SOURCE

CLASS 2000 METER

13 62-0389-03

4.3.2 Installing the Solid-Core Current Sensor Assembly

The optional solid-core current sensors can be installed in the same applications as

the standard split-core units, however, the conductors that they are monitoring must

first be disconnected.

NOTE: Under no circumstances is this operation to take place without shutting off the

power to the conductor(s) being monitored.

With the power off, disconnect the conductor from its breaker or terminal. Slide the

solid-core current sensor over the conductor, making sure that the indicator on the

sensor is pointing in the direction of the load. After this is done, reconnect the

conductor and verify that it is properly installed.

Run the black and white wires from the solid-core current sensors and install them

according to the standard installation diagram. When this is completed, the power to

the monitored conductor can be turned back on.

Fig. 6. Solid-core Current Sensor.

4.3.3 Current Sensor Wiring

Once all the current sensors are installed on their appropriate phase conductors, you

can begin terminating the current sensors on to the Class 2000 main power board.

The current sensor leads can be extended up to 2,000 feet (using #14-22 AWG wire)

for remote monitoring applications. Consult your local electrical codes for proper wire

sizing (#22 AWG twisted pair wire with a black and white conductor, rated for 600 VAC

recommended.)

The current sensor connection points are located on the bottom right of the main

power board. Three removable plugs exist, one for each current sensor phase input.

The header portions of the connectors are labeled A, B and C. Text on the plastic cover

of each of the connectors instruct you which terminal of the plug is for the white

conductor and which terminal is wired to the black conductor. Once each current

sensor is wired to its respective plug, insert each plug into the appropriate header.

CLASS 2000 METER

62-0389-03 14

4.4 MAINS Line Voltage & Current Sensor Wiring

Diagrams

Fig. 7. 3-Phase, 4-Wire Installation Diagram.

Fig. 8. 3-Phase, 3-Wire Installation Diagram.

LINE VOLTAGE CURRENT SENSORS

N

LOAD SOURCE

M33185

3-PHASE, 4-WIRE INSTALLATION DIAGRAM

NOTES:

LINE VOLTAGE CONNECTIONS: #14-12 AWG

SENSOR CONNECTIONS: B = BLACK LEAD W = WHITE LEAD

NEUTRAL NOT USED IN DELTA SYSTEM. REMOVE NEUTRAL TERMINAL

BLOCK SCREW FOR DELTA SYSTEMS.

1/10A 600 VAC INLINE FUSE PER CONDUCTOR. LITTLEFUSE PART

NUMBER KLDR.100.

1

111

C

W B W B

NPE W B

LINE VOLTAGE CURRENT SENSORS

LOAD SOURCE

M33186

3-PHASE, 3-WIRE INSTALLATION DIAGRAM

NOTES:

LINE VOLTAGE CONNECTIONS: #14-12 AWG

SENSOR CONNECTIONS: B = BLACK LEAD W = WHITE LEAD

NEUTRAL NOT USED IN DELTA SYSTEM. REMOVE NEUTRAL TERMINAL

BLOCK SCREW FOR DELTA SYSTEMS.

1/10A 600 VAC INLINE FUSE PER CONDUCTOR. LITTLEFUSE PART

NUMBER KLDR, 100.

1

111

W B W B

NPE W B

CLASS 2000 METER

15 62-0389-03

Fig. 9. Single-Phase, 3-Wire Installation Diagram.

W B W BN

LINE VOLTAGE CURRENT SENSORS

N

SINGLE-PHASE, 3-WIRE CONNECTION

120/208/240-VOLT SINGLE-PHASE

LOAD SOURCE

M34223

NOTES:

LINE VOLTAGE CONNECTION: #14 AWG

SENSOR CONNECTION: B = BLACK W = WHITE

IMPORTANT: LINE VOLTAGE MUST BE PRESENT AT THE A- AND

B-PHASE VOLTAGE TERMINALS.

SHORTING LINK MUST BE INSTALLED ON C-PHASE CURRENT

SENSOR TERMINALS.

1/10-AMP INLINE FUSES RECOMMENDED.

11

PE

1

CLASS 2000 METER

62-0389-03 16

4.5 Installation Overview

Fig. 10. Install Overview.

4.6 Check Polarity of the Current Sensor.

Verify all phases are loaded by at least 1% of meter rated load, and check the polarity

of the sensors.

Test the sensors wires one pair at a time, verifying polarity, phase rotation and

correspondence to line input. Safety guards must be in place.

CAUTION: High voltage - extra care must be taken.

Fig. 11. Sensor Polarity. When current sensor is installed properly, error LED is off. If

the Error LED is illuminated, then disconnect the gray plug and reverse the input lead.

If it clears, the “Sensor Error” then mark appropriately. Repeat for all sensors.

M34224

METER TERMINAL

BLOCK CONNECTIONS

CURRENT SENSOR AND

VOLTAGE CONNECTIONS

CLASS 2000 METER

17 62-0389-03

Fig. 12. Error LED.

Repeat the process for the C sensor gray plug. With only the C sensor plug connected,

if the sensor error remains clear, then the C sensor input and the polarity is correct.

Fig. 13. Error LED.

CLASS 2000 METER

62-0389-03 18

5.0 MONITORING MULTIPLE LOADS WITH

ONE METER

The Class 2000 meter provides extreme flexibility by allowing additional sets of current

sensors to be used in parallel so that multiple load locations can be monitored by one

meter. This feature allows a totalized display readout from two or more load circuits.

You may use parallel sensors to monitor specific breakers from one panel, specific

breakers from more than one panel, two or more complete panels, etc.

When paralleling current sensors, the following rules must be followed for accurate

readings:

Rule 1: Current sensors must be installed in complete sets of three, with a maximum of

three sensors installed in parallel per phase.

Rule 2: All sensors used in parallel must be of the same amperage rating (i.e. 100

amp, 200 amp, etc.) The rating is determined by the current rating (amperage) of the

Class 2000 meter. For example, a 200 amp meter must use extra sets of 200 amp

current sensors.

Rule 3: All locations being monitored must have the same power source. A 480 volt

meter cannot monitor a 208 volt load nor can a meter monitor two 480 or 208 volt loads

if they are from different originating power sources or from different transformers.

Rule 4: The display readings must be multiplied by the number of sets of current

sensors installed. E.g. meter reading of 5 kWh with 2 sets of current sensors....5 x 2 =

10 kWh (actual usage.)

NOTE: One set of current sensors equates to three sensors, one per phase. The

multiplier only applies when extra sets of current sensors are installed on one

meter. Therefore, if you are using only one set of three sensors (one per

phase) the multiplier is not required.

CLASS 2000 METER

19 62-0389-03

Fig. 14. Multiple Loads with one Meter.

LINE VOLTAGE

ØA

ØB

LOAD SOURCE N

LOAD A

LOAD B

CURRENT SENSORS

LOAD SOURCE

ØA

ØB

N

M33187

ØC

ØC

ØAØBØC

ØAØBØC

W B W B W BN PE

CLASS 2000 METER

62-0389-03 20

6.0 KWH METER FEATURES & FUNCTIONS

6.1 KWh Meter Display Features

Fig. 15. Normal Mode (kWh Reading).

The Class 2000 kWh meter display requires no multiplier and shows kilowatt-hours

consumed. See section 6.2 for information on calculating cost based on kWh usage.

Fig. 16. KW Load Mode (Current Load in kW).

The Class 2000 kWh meter LOAD display shows the present circuit load in kilowatts.

.

Fig. 17. Start Up Mode.

When initially powered on, the Class 2000 meter will display the startup screens.

This screen indicates the meter voltage, amps and service configuration. It will remain

on for approximately five seconds before switching to the version screen, after which

the meter enters the normal operating mode.

Table of contents

Other E-Mon Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

TESTO

TESTO 512 instruction manual

Badger Meter

Badger Meter ModMAG M2000 Installation and operation manual

Sierra

Sierra InnovaMass i Series Preliminary Instruction Manual

Utilitech

Utilitech CMG-102 Care and maintenance

Fleet Focus

Fleet Focus FF2000 user guide

Rosemount

Rosemount 8750WA Quick installation guide