Quick Installation Guide

00825-0100-4750, Rev BA

June 2009

Rosemount 8750WA

10

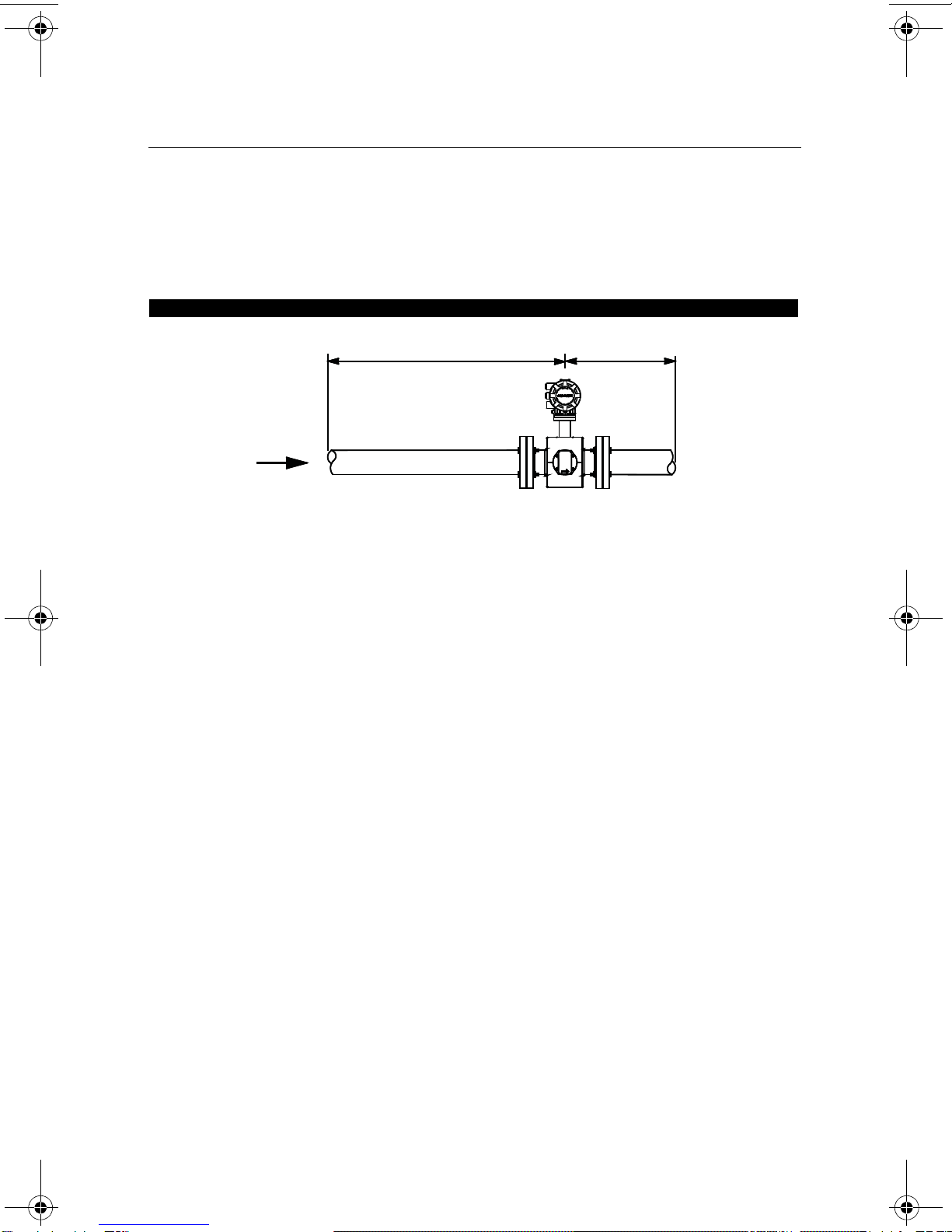

Wafer Sensors

Gaskets

The sensor requires a gasket at each of its connections to adjacent devices or piping. The gasket

material selected must be compatible with the process fluid and operating conditions. Metallic or

spiral-wound gaskets can damage the liner. Gaskets are required on each side of a

grounding ring.

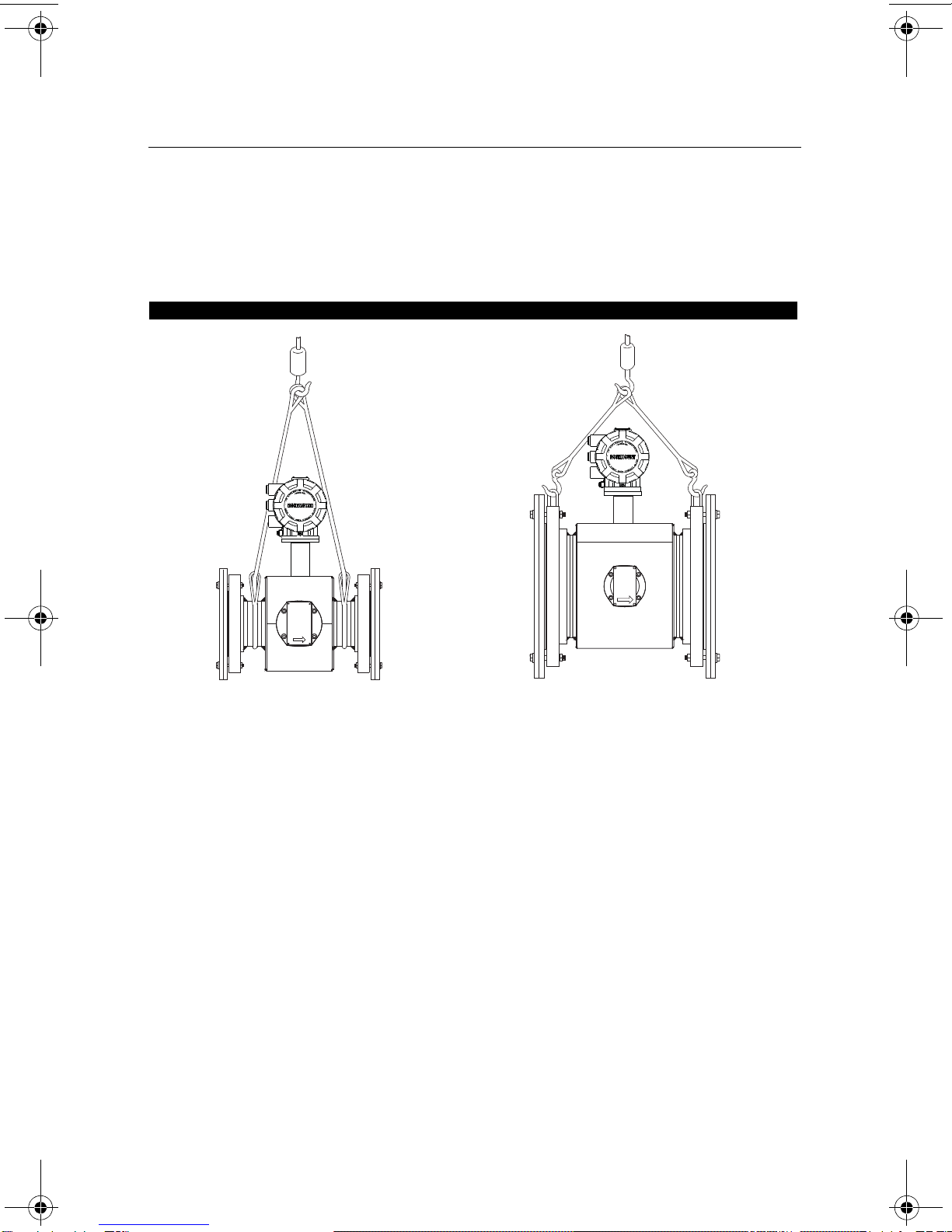

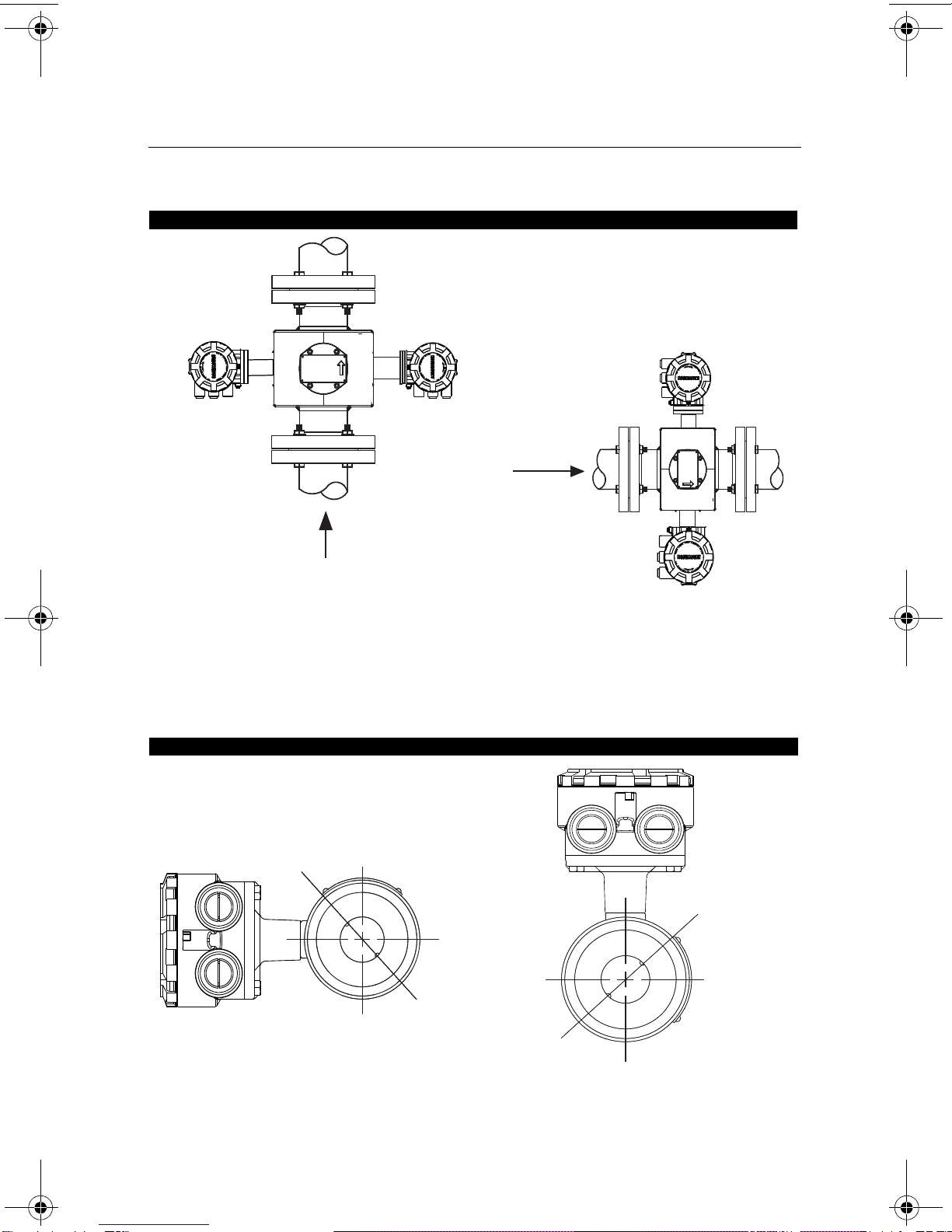

Alignment and Bolting

1. On 1.5 - through 8-inch (40 through 200 mm) line sizes. Rosemount strongly

recommends ordering the centering rings to insure proper centering of the sensor

between the process flanges. Place the alignment rings over each end of the sensor.

The smaller line sizes, 0.5 and 1 in. (15 and 25 mm), do not require centering rings.

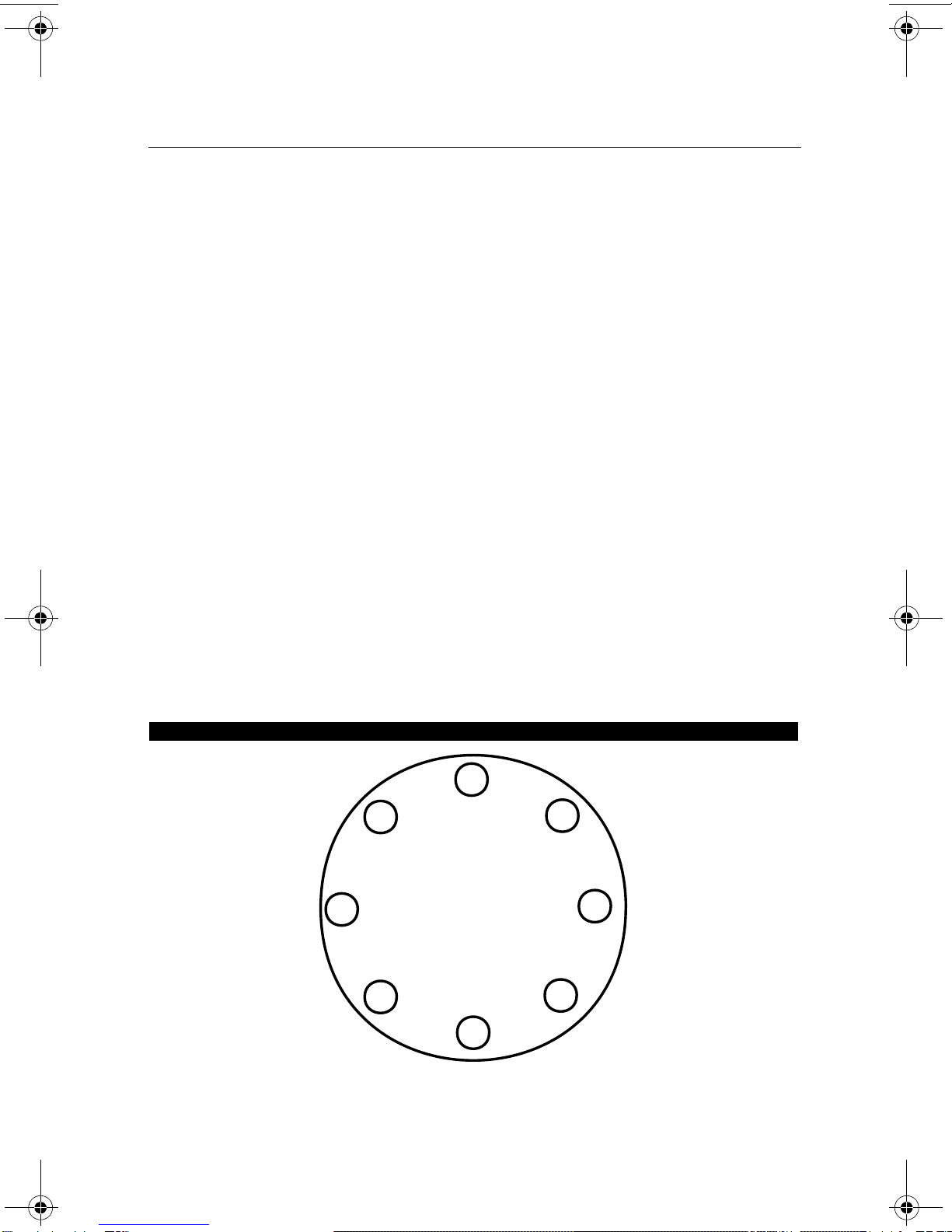

2. Insert studs for the bottom side of the sensor between the pipe flanges. Stud

specifications are listed in Table 2.

NOTE

Using carbon steel bolts on smaller line sizes, 0.5 and 1 in. (15 and 25 mm), rather than the

required stainless steel bolts, will degrade performance.

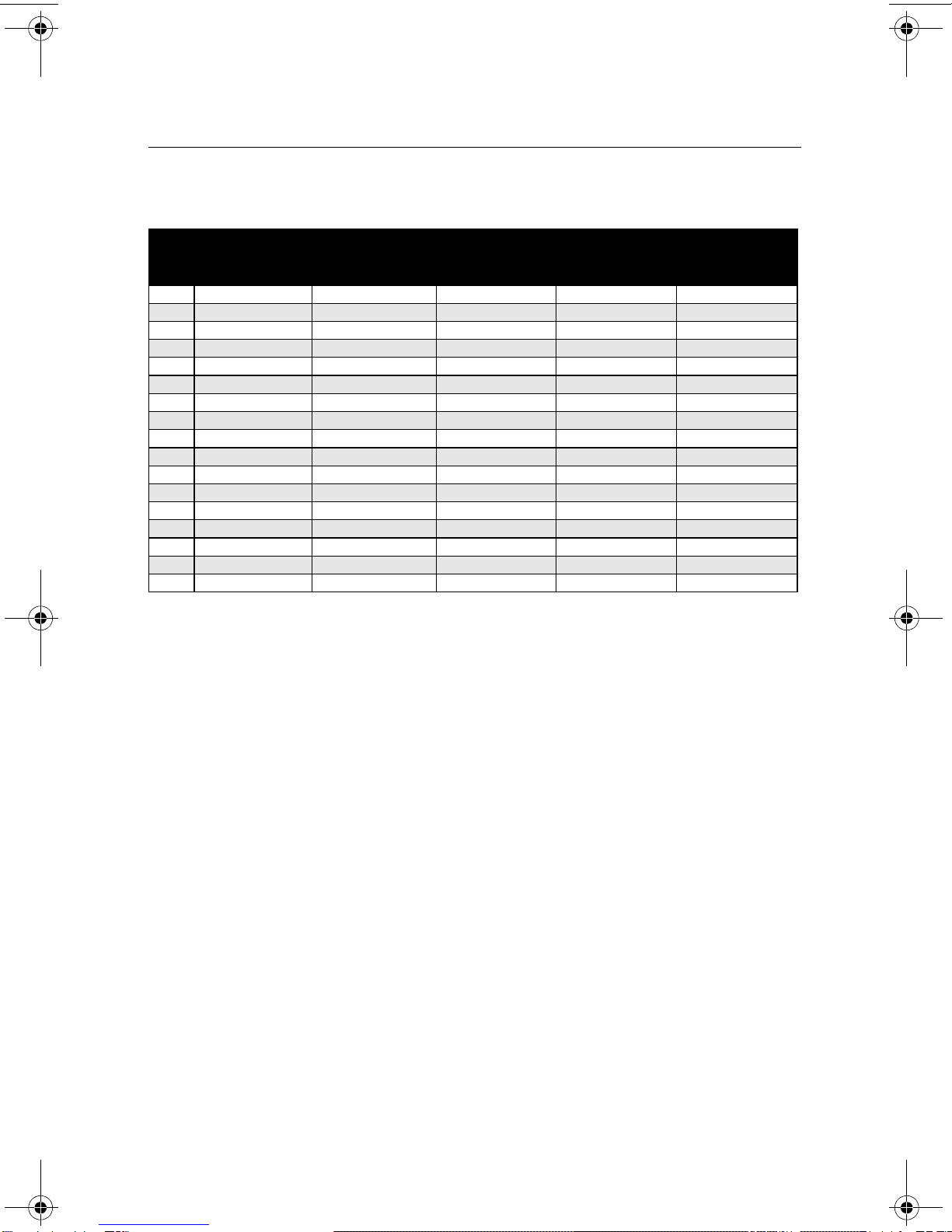

Table 1. Suggested Flange Bolt Torque Values for Rosemount 8750WA Flanged Sensors

PTFE Polyurethane/Neoprene liner

Size

Code Line Size Class 150

(pound-feet) Class 300

(pound-feet) Class 150

(pound-feet) Class 300

(pound-feet)

005 0.5 inch (15 mm) 8 8 - -

010 1 inch (25 mm) 812 - -

015 1.5 inch (40 mm) 13 25 7 18

020 2 inch (50 mm) 19 17 14 11

030 3 inch (80 mm) 34 35 23 23

040 4 inch (100 mm) 26 50 17 32

060 6 inch (150mm) 45 50 30 37

080 8 inch (200 mm) 60 82 42 55

100 10 inch (250 mm) 55 80 40 70

120 12 inch (300 mm) 65 125 55 105

140 14 inch (350 mm) 85 110 70 95

160 16 inch (400 mm) 85 160 65 140

180 18 inch (450 mm) 120 170 95 150

200 20 inch (500 mm) 110 175 90 150

240 24 inch (600 mm) 165 280 140 250

300 30 inch (750 mm) 195 415 165 375

360 36 inch (900 mm) 280 575 245 525

4750RevBAQIG.fm Page 10 Thursday, July 16, 2009 3:52 PM