E-T-A ControlPlex CPC20PN User manual

User Manual ControlPlex®

CPC20PN Controller

2

2 General information

This manual points out possible danger for

your personal safety and gives instruction

how to avoid property damage. The

following safety symbols are used to

draw the reader's attention to the safety

instructions included in this manual.

Danger!

Danger to life and limb unless the following

safety precautions are taken.

Warning

Danger to machinery, materials or the

environment unless the following safety

precautions are taken.

Note

Information is provided to allow a better

understanding.

Caution

Electrostatically sensitive devices (ESD).

Devices must exclusively be opened by

the manufacturer.

Disposal guidelines

Packaging can be recycled and should

generally be brought to re-use.

2.2 Qualified personnel

This user manual must exclusively be used

by qualified personnel, who are able –

based on their training and experience – to

realise arising problems when handling the

product and to avoid related hazards. These

persons have to ensure that the use of the

product described here meets the safety

requirements as well as the requirements

of the presently valid directives, standards

and laws.

2.3 Use

The product is part of a continuous

enhancement process. Therefore there

might be deviations between the product

in hand and this documentation. These

deviations will be remedied by a regular

review and resulting corrections in future

editions. The right to make changes

without notice is reserved. Error and

omissions excepted.

2.4 Delivery state

The product is supplied with a defined

hardware and software configuration.

Any changes in excess of the documented

options are not permitted and lead to

liability exclusion.

3

3 General description

Requirements regarding transparency

and flexibility are constantly growing in

industrial applications. Modern automation

technology meets these requirements

with cross-linked components and their

communication capabilities in a range of

business levels and sectors. Control and

computer-aided solutions are no longer

the sole focus, but monitoring of individual

components and processes becomes

more and more important. This is exactly

the target application area of the intelligent

and bus-capable power distribution

system ControlPlex®. It serves for the

protection of industrial applications as

well for monitoring and control. The

CPC20 bus controller is the centre piece

of the system. It analyses measuring

data, indicates error and transmits the

information to the superordinate control

systems by means of standard bus

systems. Its OPC* UA interface offers the

option of direct communication with a

company’s IT infrastructure.

The CPC20 has been designed as a

system in connection with module

18plus. It consists of a supply module for

supply of max. 80 A. Up to 16 connection

modules can be connected, each of them

accommodating one double-channel

electronic circuit protector. In the end

the user has max. 32 channels for his

protection system. When using a transfer

module, the number of channels can even

be doubled once more. Thus the CPC20

offers a maximum number of 64 channels.

Communication options comprise

transmission of the operating condition, of

measuring values and device information

regarding the connected components,

but also changes of the product-specific

parameters such as current ratings and

execution of actions, e.g. ON and OFF

operation.

Information can be transmitted in a cyclical

or non-cyclical mode to the superordinate

control system, the Ethernet interface

or via an available service interface to

the connected service computer. If no

connection is available to a superordinate

control unit, this will have no effect on

the behaviour of the connected circuit

protectors. The bus controller is able to

ensure their functionality even without a

connection to a superordinate control unit.

The saved parameters will be used for this

purpose.

The ControlPlex®intelligent power

distribution system offers the well-known

E-T-A quality and reliability with regard to

overcurrent protection in combination with

the innovative functionalities on the score

of automation technology.

* under preparation. Can be retrofitted via firmware update when available.

4

3.1 Design of the entire system

The CPC20 bus controller is the centre

piece of the ControlPlex®system. It allows

consistent communication between the

ESX60D electronic circuit protectors and

the superordinate control level, connected

HMIs and even into the Cloud.

The PROFINET interface to the

superordinate control unit is implemented

as two RJ45 connectors. It allows

connection of the required control unit with

the ControlPlex®system, This enables

display, analysis as well as diagnosis of the

individual measuring values. In addition, it

allows control of the individual electronic

circuit protectors. An additional Ethernet

interface enables direct access of the

integral web server of the bus controller.

Service staff can thus directly access the

system on site. Moreover, access via the

connected infrastructure of the company

is enables and thus global access. OPC

UA* and MQTT* allow transmission of all

measuring values and status information

e.g. to a superordinate cloud application,

independently of the control system.

Revised measuring values of all electronic

circuit protectors are also forwarded to

the automation system. This enables the

user to have unrestricted access to the

safety-relevant functions even in the event

of an interruption. Any occurring failures

will be detected quickly and can be

remedied without delay. The ControlPlex®

system effectively reduces system

downtimes and significantly increases

the productivity.

16 power distribution modules with up to

16 2-channel ESX60D electronic circuit

protectors can be directly connected to

the CPC20 bus controller. This number

can be doubled with the transfer module.

Thus the bus controller operates up to 64

channels. This is done in a cycle time of

520 ms.

fig. 1: System overview

* under preparation. Can be retrofitted via firmware

update when available.

MM

CPUCPU

HMIHMI

ERP MES

Central computer

Online services

Remote

maintenance

5

3.2 Dimensions

CPC20

3.3 Dimensions

18plus-EM03 supply module

fig. 2: Dimensions CPC20

fig. 3: Dimensions of 18plus-EM03 supply module

3.4 Dimensions

18plus- AM03 connection module

3.5 Dimensions

18plus-TM03 transfer module

fig. 4: Dimensions of 18plus-AM03 connection module

fig. 5: Dimensions of 18plus-TM03 transfer module

7.5

105 ± 1

43

symmetrical rail to EN 60715-35x7.5

24

69

130 ± 1

130±0.8

42.5

13.5

7.5

130±0.8

66.3

34.7

58.3

42.5

13.1

7.5

130±0.8

13.5

7.5

6

3.6 Dimensions of 18plus-AM03 connection module with

ESX60D

3.7 Status indication and terminals

130±0.8

105±1

13.1

7.5

fig. 6: Dimensions of 18plus-AM03 connection module fitted with ESX60D

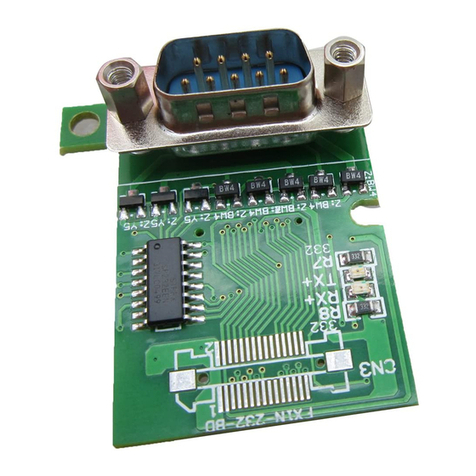

fig. 7: Status indication and terminals CPC20

-XD1 supply

LED US1

LED BF

LED SF

-X3 USB service interface

-X2 extension interface

-X1 Ethernet interface

-XF2 PROFINET interface

-XF1 PROFINET interface

Type CPC20PN-T2

US1

BF

SF

USB

X3

X2

COM-2

ETH

X1

XF2

XF1

PROFINET

16/ADR

15/ELB

++0V 0V

7

3.7.1 Terminals for voltage supply

supply XD1

Voltage ratings: DC 24 V (± 10 % 18 ... 30 V)

Rated current: typically 160 mA

Terminal design: 4 x push-in terminals (+/+/0V/0V)

Max. cable cross section rigid 0.2 – 2.5 mm2

flexible with wire end ferrule (with plastic sleeve) 0.2 – 2.5 mm2

flexible with wire end ferrule (without plastic sleeve) 0.2 – 2.5 mm2

stripping length 11 mm

Using a supply voltage outside the indicated operating range can cause

malfunctions or destruction of the device.

The CPC20 has a direct and fixed connection between the housing shield of

the RJ45 connectors (XF1, XF2 and X1) and the 0V of X41.

3.7.2 Connector for the additional ELBus®

X2 Direct connection with 18plus (no wiring required)

X52COM-2: Connection for the second power distribution system 18plus

Cable length max. 3 m

typically H07V-K 1.5 mm²

15: Data line ELBus®COM

16: Addressing

Use of the terminals for applications not provided for in the operation manual

or improper connection can lead to malfunction or destruction of the device.

3.7.3

USB service and maintenance interface, terminal X3)

The USB interface serves for connection of the service computer. The available user

software ControlPlex® Views provides the option to carry out firmware updates.

X2

18plus-TM03

connection

sleeve

16. Supply voltage ELBus®+ 24 V

15. Data line ELBus®

15

16

fig. 8: ELBus®connection

130±0,8

42,513,5

7,5

8

fig. 9: Signalling RJ45 connectors

3.7.4 PROFINET interfaces with integral switch, connection

sleeve XF1, XF2

XF1 Connection to bus system PROFINET

Type: RJ45

When wiring and connecting to the bus system PROFINET the installation and wiring

regulations of the PROFIBUS User Organisation (PNO) have to be observed.

XF2 Connection to bus system PROFINET

Type: RJ45

When wiring and connecting to the bus system PROFINET the installation and wiring

regulations of the PROFIBUS User Organisation (PNO) have to be observed

LED colour description

US1 green Normal duty, SF or BF possible.

orange The breaker is in the start-up phase.

red blinking Firmware update is presently carried out.

BF orange The breaker is in the start-up phase.

red blinking Firmware update is presently carried out.

red Bus error

SF orange The breaker is in the start-up phase.

red blinking Firmware update is presently carried out.

red System error

ACT OFF No activity

blinking

yellow Activity available

LNK

OFF No link available

green

blinking PROFINET devices localisation

green Link available

XF2

LED ACT

LED LNK

LED ACT

LED LNK

XF1

3.7.5 ETHERNET interface, connection sleeve X1

X1 connection with bus controller CPC20

Type: RJ45

3.7.6 LED status indication

9

4 Mounting and installation

4.1 Mounting of the system

The preferred mounting position of the ControlPlex system is horizontal.

fig. 10: Installation drawing

10

fig. 11: System installation

4.2 System installation

Connection of CPC20 bus controller

with 18plus-TM03 transfer module for

extension of the number of circuit protec-

tors to be connected to 32 devices.

The connection between CPC20 and the

18plus-TM03 has to be realised manually.

PROFINET

DC 24 V +

18plus-AM03 with CPC20

18plus-AM03 with 18-plus-TM03

DC 24 V GND

11

5 Operating modes of the CPC20 bus controller

5.1 Operating mode: Start-up mode

The CPC20 bus controller is initialised by applying the supply

voltage. The device will carry out implemented programme

memory tests and self test routines. During this time a

communication via the interfaces is not possible.

5.2 Operating mode: System error mode

If a failure is detected during the self test routines, the bus

controller will change into operating mode System Error. This

operating mode can only be discontinued by way of re-starting

the device and it prevents the data exchange via the interfaces.

If the bus controller is in this operating mode, it is unable to

control the electronic circuit protectors and these will stay in the

stand-alone mode (overcurrent protection).

5.3 Operating mode: Configuration error

mode

If there are no valid or invalid configuration data available in

the bus controller, it will change into this operating mode. This

operating mode only allows non-cyclical data exchange. Cyclical

data exchange is prevented. Leave this operating mode upon

receipt of the correct slot parameters and configuration data.

5.4 Operating mode: stand-alone mode

In normal duty there is a connection between the bus controller

and the superordinate control unit. Thus the control of the

electronic circuit protectors and the change of their parameters

is executed by the superordinate control unit. Should the

communication between both participants fail, this has no

influence on the protective function of the circuit protectors. In

this case the CPC20 bus controller will automatically adopt the

control and parameterisation of the electronic circuit protectors,

because all required data sets are saved within the CPC20. By

means of the web server, the electronic circuit protectors, their

status and parameters can be accessed via the Ethernet interface

interface. It is thus possible to change e.g. parameter data of

the various electronic circuit protectors. If the failure on the

communication level is remedied, this operating mode will be left

and the superordinate control unit will take over control again as

master. If during this time a parameter was changed while there

was no communication, this will be signalled to the superordinate

control unit. In this case the user can correspondingly define the

control behaviour and it can be programmed in the programmable

control unit. This allows the user to select a reaction meeting his

requirements.

5.5 Operating mode: Slave mode

In this operating mode the CPC20 is involved in a PROFINET

system. Communication to the CPC20 bus controller works

faultlessly and the controller can be addressed and controlled

by the superordinate control unit.

The behaviour of the bus controller with simultaneous use of

a field bus interface and of the web server or the USB service

and maintenance interface can be determined by means of the

configuration of the device in the superordinate control unit. It can

be pre-selected there that Ethernet and/or the USB service and

maintenance interface are granted either only reader access or

reader and editor access. In the event of editor access, changes

of the parameterisation of the electronic circuit protectors can be

carried out in parallel to the field bus system. These parameter

changes will then be advised to the superordinate control system

and can be adopted by it or also overwritten. The user can select

the behaviour accordingly.

12

5.6 Operating mode: Firmware Update Mode

The devices are supplied with a software programmed according

to their functionality. If the functions of the devices are extended,

this will be carried out in the firmware. It is therefore necessary to

carry out a firmware update if the new functionality shall be used.

6 Basic functionalities of the entire system

6.1 Internal cycle times 6.2 Hot swap of circuit protectors

The cycle time of the system depends on the number of data

to be transmitted between the CPC20 bus controller and the

projected slots for the ESX60D electronic circuit protectors.

It is possible to choose the data quantity for the communication

ot the superordinate control unit. This can be achieved by using

the different data models. It is therefore possible to transmit

either the status, the measuring values for the load current and

the output voltage of the electronic circuit protector or to only

send the circuit protector status to the superordinate control unit.

The choice between the various data models is made available

to the user in the GSDML file of the control system. These are

configuration data which are transmitted to the store programme

control by means of the hardware configuration of the CPC20.

The cycle time per bus with 16 18plus-AM03 modules is approx.

520 ms for the cyclical data. A window of 70 ms is kept free for

non-cyclical data. In total, this is a max. cycle time of 590 ms.

The ESX60D electronic circuit protectors can be plugged

into the 18plus-AM03 power distribution module at any time.

After plugging in a circuit protector, it will automatically be

parameterised if parameters are available for the slot in question.

Transmission of the parameters will be without interruption of the

cyclical data exchange between the CPC20 and the ESX60D

electronic circuit protector.

13

6.3 Communication via the

USB service interface

The maintenance and service interface allows direct access to

the CPC20 bus controller. Firmware updates for the CPC20 are

possible via this interface.

6.4 About the additional

Ethernet interface

The additional Ethernet interface extends the functional scope

of the bus controller. The following functionalities are provided

via this interface.

6.4 1 Web Server

The web server offers the entire scope of measuring data, status

information, parameterisation options an d control function of

the CPC20 bus controller. The parameterisation of the interface

is described separately.

6.4.1.1 Default IP address -X91

The default IP address of the CPC20 is: 192.168.1.1

The web server can be reached via this IP address.

6.4.1.2 User name and password

In order to be able to carry out configurations, the user has

to have the required access authorisation. It is defined in user

administration.

The default settings are:

User: admin

Password: admin

We urgently recommend to individually adjust these

settings upon startup of the device.

14

7 Communication via PROFINET

7.1 ControlPlex®device model

Up to two power distribution systems can be connected to the

CPC20 controller. They consist of the 18plus-EM-03 supply, the

18plus-AM03 connection modules and for the external system,

communication is run via the 18plus-TM03 transfer module. These

blocks are purely passive. Up to 16 18plus-AM03 connection

modules can be configured in slots 2 and 3. The 18plus-AM03

connection modules, which can be directly mounted side-by-side

with the CPC20, are configured at slot 2. The 18plus-AM03

connection modules connected to the 18plus-TM03 transfer

module are configured at slot 3.

The power distribution system ControlPlex®uses the following

PROFINET model:

fig. 13: Device model

Bus interface SubSlot 1

I/O Data

CPC20PN

2 bytes input

SubSlot 1

Total current

2 bytes input

SubSlot 2

status/control

Min. 1/1 byte*

max. 32/32 bytes*

SubSlot 3

Measuring values

min. 16 bytes*

Inp.* max. 128

SubSlot 1

Total current

2 bytes input

SubSlot 2

status/control

Min. 1/1 byte*

max. 32/32 bytes*

SubSlot 3

Measuring values

min. 16 bytes*

Inp.* max. 128

Slot 0 Slot 1 Slot 2 Slot 3

DAP CPC20PN CPC20/ 18plus-

18plus-AM03 -TM03/-AM03

15

PROFINET CPC20PN

Device The CPC20PN controls itself. It has the following features:

– The PROFINET interface (DAP) via which the master communicates with the CPC20PN

– CPC20PN holds the status of the controller.

– CPC20 / 18plus-AM03 connection module: it is possible to configure 1 to 16 modules.

18plus-TM03 transfer module / 18plus-AM03 connection module: it is possible to configure 1 to 16 modules.

Slots Slot 0:

Modules are shown here which are required for the PROFINET communication.

They do not have to be configured further.

Slot 1:

Here are the I/O data of the CPC20 controller. A sub-module with firm I/O assignment has already been

»plugged« in this slot. This sub-module contains 2 input and output bytes which are described in more detail

in the chapter Module I/O Data CPC20 controller.

This slot is firmly installed and cannot be removed.

Slot 2 -3:

The slots 2-3 correspond to the terminals of the 18plus-AM03 and hold three sub-module slots which

can be occupied dynamically by the PLC configuration.

The module type is not directly checked, i.e. if 4 x- AM03 modules are »plugged-in« during the project

planning stage, but eventually 8 x 18plus modules are connected, this configuration will boot correctly.

However, in this case only the first 4 circuit protectors will be included in the cyclical data exchange,

the remaining 4 will not be contained in the process data image.

The reverse case is equally allowed (8 x 18plus- AM03 module planned, but only 4 x 18plus-AM03

connected. In this case the lacking circuit protectors will be signalled as »not available« in the cyclical

process data image).

SubSlots Each module has three sub-slots:

Slot 1: total current of all connected channels

Slot 2: status and control bytes of the circuit protectors

Slot 3: measuring values of the circuit protectors

A corresponding sub-module (from the GSDML file) can be »plugged« into each slot or the slot can remain

empty. If the slot remains empty, no cyclical process data will be exchanged for the slot.

The quantity of the cyclically to be exchanged process data can be determined via this mechanism (on the

level of the number of 18plus modules) depending on the application.

fig. 14: Communication properties

16

7.2 GSDML file

The IODD file is in the download area of the E-T-A website and can be downloaded there.

7.3 I&M data (identification & maintenance)

The following I&M data are made available by the CPC20 controller:

I&M data length data set meaning

MANUFACTURER_ID 2 bytes I&M0 manufacturer identification 0696h

ORDER_ID 20 bytes I&M0 part number

SERIAL_NUMBER 16 bytes I&M0 serial number

HARDWARE_REVISION 2 bytes I&M0 revision index

SOFTWARE_REVISION 4 bytes I&M0 firmware version

REVISION_COUNTER 2 bytes I&M0 revision counter

PROFILE_ID 2 bytes I&M0 profile ID 0000h

PROFILE_SPECIFIC_TYPE 2 bytes I&M0 profile-specific coding 0004h

IM_VERSION 2 bytes I&M0 version of the I&M data 0101h

IM_SUPPORTED 2 bytes I&M0 supported data sets 002Eh

TAG_FUNCTION 32 bytes I&M1 unambiguous marking

throughout the plant

TAG_LOCATION 22 bytes I&M1 installation area

INSTALLATION_DATE 16 bytes I&M2 installation date and time

DESCRIPTOR 54 bytes I&M3 comments

fig. 15: I&M data

17

8 Cyclical I/O data

Depending on the planned module type and the selected

sub-modules, a varying number of data bytes are exchanged in

the cyclical data traffic.

The system allows individual determination per slot if I/O data

(status/control), measuring values and/or total current shall be

transmitted. The GSDML file made available for the projecting

tool allows the related configuration the system recognises all

permitted configurations and processes the cyclical data defined

in the projection.

Only the module I/O data CPC20 controller is firmly pre-set and

cannot be removed because the input bytes hold vital failure and

diagnostic information as described in the following.

byte type range description

status controller 0 HighByte

1 LowByte

Word 0xFFFF Bit 0 = no configuration data available

Bit1 = invalid configuration data

bit 2 = reserve

bit 3 = reserve

Bit4 = command buffer overflow

bit 5 = reserve

bit 6 = reserve

Bit7 = no communication with at least one PWR board

Bit8 = reserve

Bit9 = CPC temporary error

Bit10 = CPC hardware error

Bit11 = reserve

Bit12 = reserve

Bit13 = reserve

Bit14 = reserve

Bit15 = reserve

fig. 16: Diagnostic data

8.2 Submodule Status/Control

Depending on the number of 18plus-AM03 connection modules

used (one 18plus-AM03 module corresponds to two channels),

per channel one byte input data with the status of the circuit

protector and one byte output data for control of the circuit

protector are exchanged here.

Example:

8 18plus-AM03 connection modules equal 16 channels. This

results in 16 bytes for status information and 16 bytes for control

for the data exchange.

Addressing is effected according to the

18plus-AM03 sequence

18plus-AM03 1, channel 1.1 byte address [0]

18plus-AM03 1, channel 1.2 byte address [1]

18plus-AM03 2, channel 2.1 byte address [2]

…….

8.1 Module I/O data CPC20 controller

The 2 bytes input data contain the following global error and

diagnostic messages. This module does not contain any output

data.

18

byte type range description

status byte Word 0…255 bit 0 = load output

bit 1 = short circuit

bit 2 = overload

bit 3 = low voltage

bit 4 = excess temperature

bit 5 = excess temperature

bit 6 = limit value current

bit 7 = event

»True« means the status is active.

byte type range description

Control 0 byte 0…255 bit 0 = load output ON/OFF

bit 1 = reset load output (only responds to rising edge)

bit 2 = reserve

bit 3 = reserve

bit 4 = reserve

bit 5 = reserve

bit 6 = reserve

bit 7 = reserve

»True« means the status is active.

8.2.1 Status circuit protector

Design of the input byte per channel is as follows (status circuit protector):

fig. 17: Status channel

8.2.2 Control circuit protector

Design of the output byte per circuit protector slot is as follows (control circuit protector):

fig. 18: Control channel

8.3 Submodule measuring values

Depending on the number of 18plus-AM03 connection modules

used (one 18plus-AM03 connection module equals two channels)

four bytes input data with measuring values of load current and

load voltage of the corresponding circuit protector are made

available per channel. The sub-module does not have output

data.

The sequence of the measuring values is load current (2 bytes),

followed by load voltage (2 bytes)

Example:

8 18plus-AM03 connection modules equal 16 channels. This results in 16*4, i.e. 64 bytes for the data exchange.

Addressing is effected according to the 18plus-AM03 sequence.

18plus-AM03 1, channel 1.1 byte address [0..1] load current, byte address [2..3] load voltage

18plus-AM03 1, channel 1.2 byte address [4..5] load current, byte address [6..7] load voltage

18plus-AM03 1, channel 2.1 byte address [8..9] load current, byte address [10..11] load voltage

…….

19

byte type range description

load current 0 HighByte

1 LowByte

Int Contains the lowest measured current of the channel since the last reset.

A standardised 16-bit-value with a resolution of 10 mA is made available.

Example for calculation of the measuring value:

Value (150): 100 = 1.50 Ampere

8.3.1 Load current circuit protector

Design of the input bytes per channel is as follows (measuring value load current):

fig. 19: Load current channel

byte type range description

Load voltage 0 HighByte

1 LowByte

Int A standardised 16-bit-value with a resolution of 10 mV is made available.

Example for calculation of the measuring value:

Value (2512): 100 = 25.12 Volt

byte type range description

Load voltage 0 HighByte

1 LowByte

Int A standardised 16-bit-value with a resolution of 10 mA is made available.

Example for calculation of the measuring value:

Value (1320): 100 = 13.20 Ampere

8.3.2 Load voltage circuit protector

Design of the input bytes per channel is as follows (measuring value load current):

8.4 Submodule total current

The sub-module total current supplies a standardised 16 Bit

value with the calculated total current of all 18plus-AM03

modules in slot (2 byte input data). The sub-module does not

have output data.

The measuring value is indicated as follows:

fig. 20: Load voltage channel

fig. 21: Total current

20

physics index digit description

Channel no. on ELBus Decimal numbers 103 and

102

Number of channel to be queried.

Valid value range: 00…32

parameter index Decimal numbers 101 and

100

The parameter index defines the data range and the data type of

the data to be read or written.

Valid value range: 01…10

Parameters

Index (W) slot slot

number

number of

data bytes

reading (R)

writing (W) description

02 1 00 19 R device information of

CPC20 controller (see chapter 9.1.1).

03 1 00 2 R/W Configuration data of

CPC20 controller (see chapter 9.1.2).

05 1 00 1 W Action commands for all channels and the

CPC20 (see chapter 9.1.3)

9 Non-cyclical data

Non-cyclical PROFINET services allow exchange of more data

with the CPC20 controller and the circuit protectors. Access

also allows direct addressing of a circuit protector. PROFINET

index and slot number are used for this. For reading and editing

controller data, slot 1 is used. Slot 2 is used for reading and

editing the channels on the CPC. Slot 3 is used for reading and

editing the channels on the extension board- (Overview of slots

see 7.1).

The index is set up as follows:

02 01

parameter index

channel no. (1-32)

The index is assigned to the following non-cyclical data areas:

Controller

fig. 23: Set-up parameter index CPC

fig. 22: Index structure

This manual suits for next models

1

Table of contents

Other E-T-A Controllers manuals

E-T-A

E-T-A EtherNetIP ControlPlex CPC12EN User manual

E-T-A

E-T-A ControlPlex CPC10PB User manual

E-T-A

E-T-A ControlPlex CPC12 User manual

E-T-A

E-T-A E-1071-623 User manual

E-T-A

E-T-A ControlPlex CPC12 T Series User manual

E-T-A

E-T-A ControlPlex CPC12 T Series User manual

E-T-A

E-T-A EM12D-TMB Series User manual

E-T-A

E-T-A EtherNetIP ControlPlex CPC12EN User manual

E-T-A

E-T-A Control Plex CPC10PB-T1 User manual

E-T-A

E-T-A ControlPlex CPC12 User manual