Eagle Eye BDS-Pro User manual

1

BDS-Pro

Battery Monitoring System

Installation Manual 122118

www.eepowersolutions.com | Tel: 1-877-805-3377 | Fax: 1-414-962-3660 | [email protected]

2

Contents

1. Introduction ............................................................................................................................. 3

1.1 Safety Information ............................................................................................................ 3

2. Product Overview ................................................................................................................... 4

2.1 Main Processing Unit (MPU) ............................................................................................ 5

2.2 Technical Specifications .................................................................................................. 7

3. Parts List ................................................................................................................................. 8

4. Installation Tools .................................................................................................................. 10

4.1 Required Tools ................................................................................................................ 10

4.2 Recommended Tools ...................................................................................................... 11

5. Hardware Installation ........................................................................................................... 12

5.1 Overview of Workflow .................................................................................................... 12

5.2 MPU Installation .............................................................................................................. 13

5.3: Clamp Installation .......................................................................................................... 14

5.4 Sensing Cable Layout & Connection ............................................................................ 17

5.5 Temperature Sensor Connection .................................................................................. 21

5.6 DC Voltage Cables .......................................................................................................... 22

5.7 Connect DC CT Clamp .................................................................................................... 24

5.8 Verify Connections ......................................................................................................... 26

5.9 Connect Cables to BDS-Pro MPU .................................................................................. 28

6. Initial Power Up ..................................................................................................................... 29

6.1 Status LEDs ..................................................................................................................... 29

6.2 Keypad Operation ........................................................................................................... 30

7. Parameter Setup & Measurement Verification ................................................................... 31

8. Network Communication Setup .......................................................................................... 36

8.1 Configure MPU IP Address ............................................................................................ 36

8.2 Connect BDS-Pro to Network ........................................................................................ 38

3

BDS-Pro Installation Manual

122118

1. Introduction

This manual provides guided steps on how to install the Eagle Eye BDS-Pro Battery Monitoring

System safely and effectively. Please read this manual carefully to fully understand the

functionality of the BDS-Pro.

1.1 Safety Information

Operation methods and safety measures described in this manual are only applicable to the

defined purpose and functionality of the BDS-Pro. If the BDS-Pro is used in a way not specified

in this manual, the safety of the equipment, personnel, and property cannot be assured.

•Please read this manual carefully to avoid accidental injury or misuse of product.

•Only qualified personnel with proper tools and equipment should work on batteries.

•To avoid damage and injury due to the short circuiting of battery terminals, wrap

insulating tape around all metallic parts.

•Do not wear metallic items such as jewelry, watches, & rings. Wear insulated gloves and

goggles when working around batteries.

•Ensure an installation supervisor is on hand when connecting the BDS-Pro and battery

post to avoid fire or personal injury.

•Make sure all personnel are fully aware of safety guidelines.

4

BDS-Pro Installation Manual

122118

2. Product Overview

The BDS-Pro is designed to monitor and analyze the state of health of up to (24) cells by

measuring and recording:

String: Voltage & DC Float / Discharge Current

Jar/Cell: Voltage, Internal Resistance / Connection Resistance, & Temperature

All BDS-Pro solutions come complete with battery management software which allows all

battery systems to be monitored 24 hours a day, 365 days a year via remote computer(s). This

software offers comprehensive battery diagnosis and reporting capabilities to ensure the

integrity of your critical backup power system.

Alternatively, systems can be configured for Modbus communication for integration to a third-

party building management system or SCADA (supervisory control and data acquisition).

The BDS-Pro is composed of the MPU (main processing unit), Sensing Cables, Connection

Clamps, & CT.

5

BDS-Pro Installation Manual

122118

2.1 Main Processing Unit (MPU)

The MPU receives battery data and communicates with the Server.

Internal Access

Terminal Strip

(DC Power, DC

Voltage Sensing, & CT

Connections)

Power Button

Controls

System Status

Indicator Lights

TCP/IP Port

(Network Communication)

RS232 Port

(Programming &

Diagnostics)

RS485/422 Ports

(Daisy Chain

Connections)

6

BDS-Pro Installation Manual

122118

7

BDS-Pro Installation Manual

122118

2.2 Technical Specifications

Applications:

Flooded, Sealed, & NiCad battery types

Up to 24 jars / cells.

Battery Capacity Range:

Up to 6000 Ah

Cell Voltage:

1 – 16 VDC

Accuracy:

DC Voltage / Current: ±0.5% / ±1%

Temperature: ±2%

Internal Resistance: ±2%

Cell Voltage: ±1%

Resolution:

AC Voltage / Current: 0.1 V / 0.1 A

DC Voltage / Current: 0.1 V / 0.1 A

Cell Voltage: 10 mV

Internal Resistance: 0.001 Ω

Temperature: 0.5 °C

Test Speed:

3 – 4 seconds per cell

Test Load:

< 2 A per cell

Display:

LED Indicator Lights

Internal Storage:

Limited On-board memory

Measuring Interval:

Adjustable from 10 min to 24 hours (voltage & resistance)

Data Transfer:

TCP/IP, Modbus Protocol

Bandwidth Use:

< 10 Kbps

Operating Environment:

Temperature: 0 – 50 °C (32 – 122 °F)

Relative Humidity: Under 80% RH

AC Power Requirements:

110 – 220 VAC, 50/60 Hz

DC Power Requirements:

48V: 43 – 72 VDC

125V: 100 – 150 VDC

Power Consumption:

15 W

Connections:

RJ45

Dimensions L x W x D:

MPU: 231 x 270 x 55 mm (9.1 x 10.6 x 2.2 in)

8

BDS-Pro Installation Manual

122118

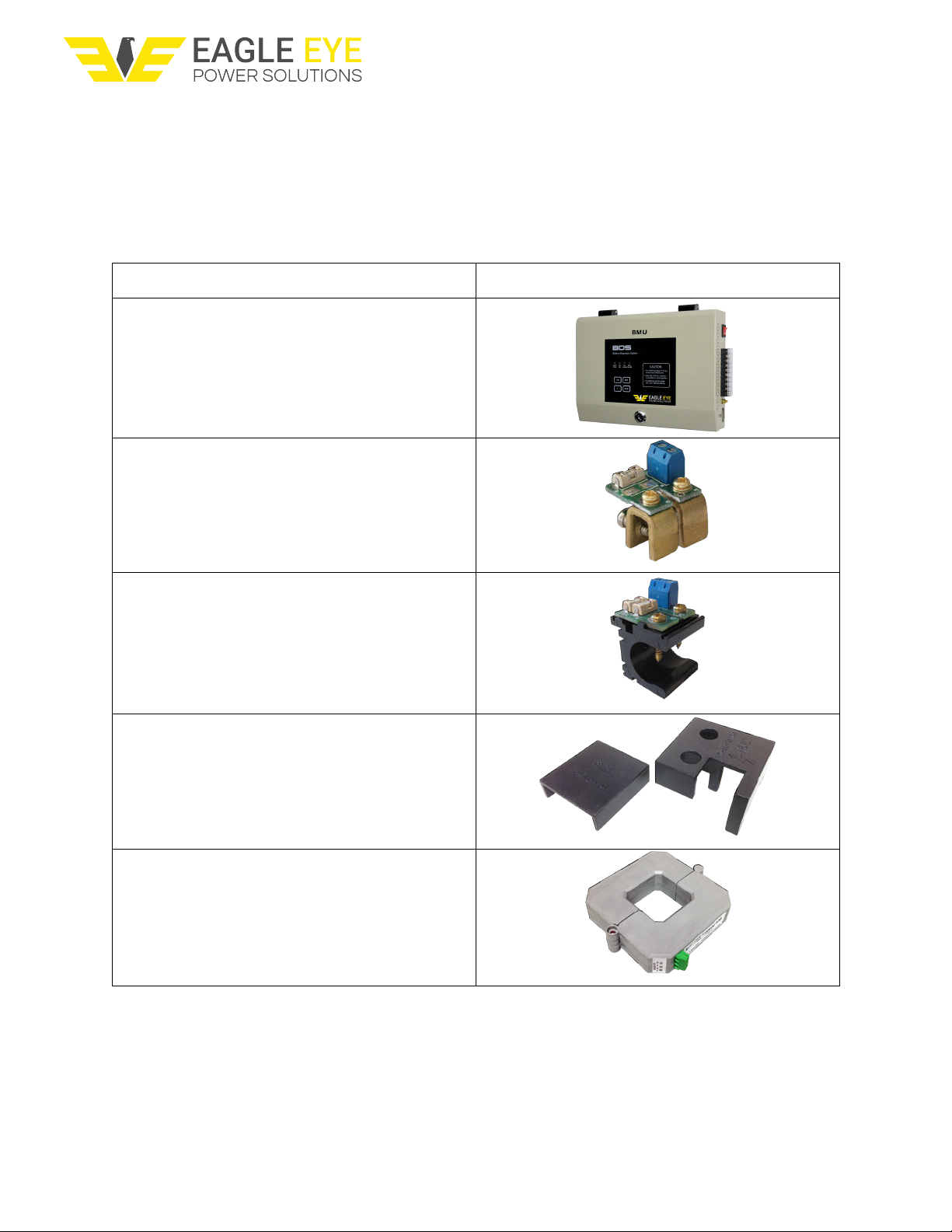

3. Parts List

The following parts come standard with each BDS-Pro package. The number and type of

connector clamps will depend on the application.

Part Name & Purpose

Picture

BDS-Pro MPU

Main processing unit for BDS-Pro system

C-Type Clamp

Clamp used for connection between batteries

with busbar inter-cell connections

O-Type Clamp

Clamp used for connection between batteries

with cable inter-cell connections

Clamp Covers: C-Type / O-Type

Placed over clamp PCB

CT Clamp

Measures DC current

9

BDS-Pro Installation Manual

122118

AC / DC Power Cable

Power cable for systems utilizing AC power

Total Voltage / DC Power Fuses

Fused lines between the Total Voltage & DC

Power cables

Total Voltage Jumpers

Allows total voltage measurement from DC

power terminations

CT Cable Harness

For connection between CT & BDS-Pro MPU

Temperature Cable Harness (4-pin)

Measures temperature of battery posts

Voltage Sensing Cable Harness (6-pin)

Measures DC voltage (Vs)

Current Sensing Cable Harness (4-pin)

Measures current (Is)

10

BDS-Pro Installation Manual

122118

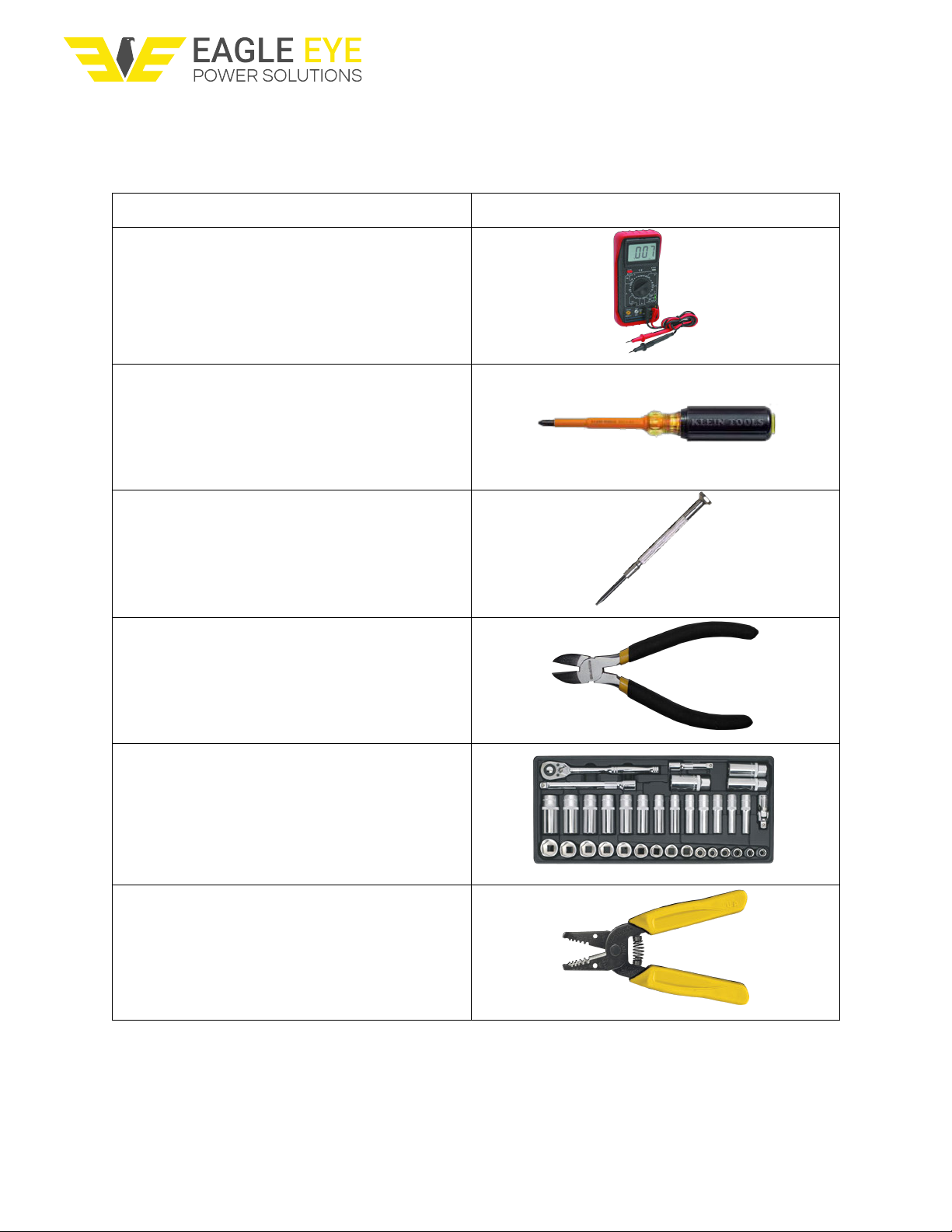

4. Installation Tools

4.1 Required Tools

Tool Name & Purpose

Picture

Multi-meter

Verification of connection voltage &

resistance

#1 Phillips Insulated Screwdriver

Tightening of O-Type/C-Type clamp screws

2/16” (2-3 mm) Flathead Screwdriver

Tightening of sensing cable

Wire Cutter

Adjustment of cable length

US or Metric Socket Set

For mounting BDS-Pro

Wire Stripper

Adjustment of cable length

Other manuals for BDS-Pro

1

Table of contents

Other Eagle Eye Measuring Instrument manuals