BTM-Series User Manual

www.eepowersolutions.com

|

Tel:

1-

877-805-3377 | Fax: 1-414-962-3660 | in[email protected] | V1.0 US IFC608.3 (2010) requires that if a sealed battery (or batteries) operated in a single

premises contains a total of 50 gallons or over of acid the proprietor must install measures to

prevent thermal runaway.

System description

The thermal sensors are small, sealed units with two wires for connection to the adjacent

sensor and an LED which activates to indicate when the cell is in over-temperature. Each

thermal sensor is sealed to IP68 (water and dust proof) and the special gel-filled connectors

provided are also sealed against acid ingress, dust and gasses.

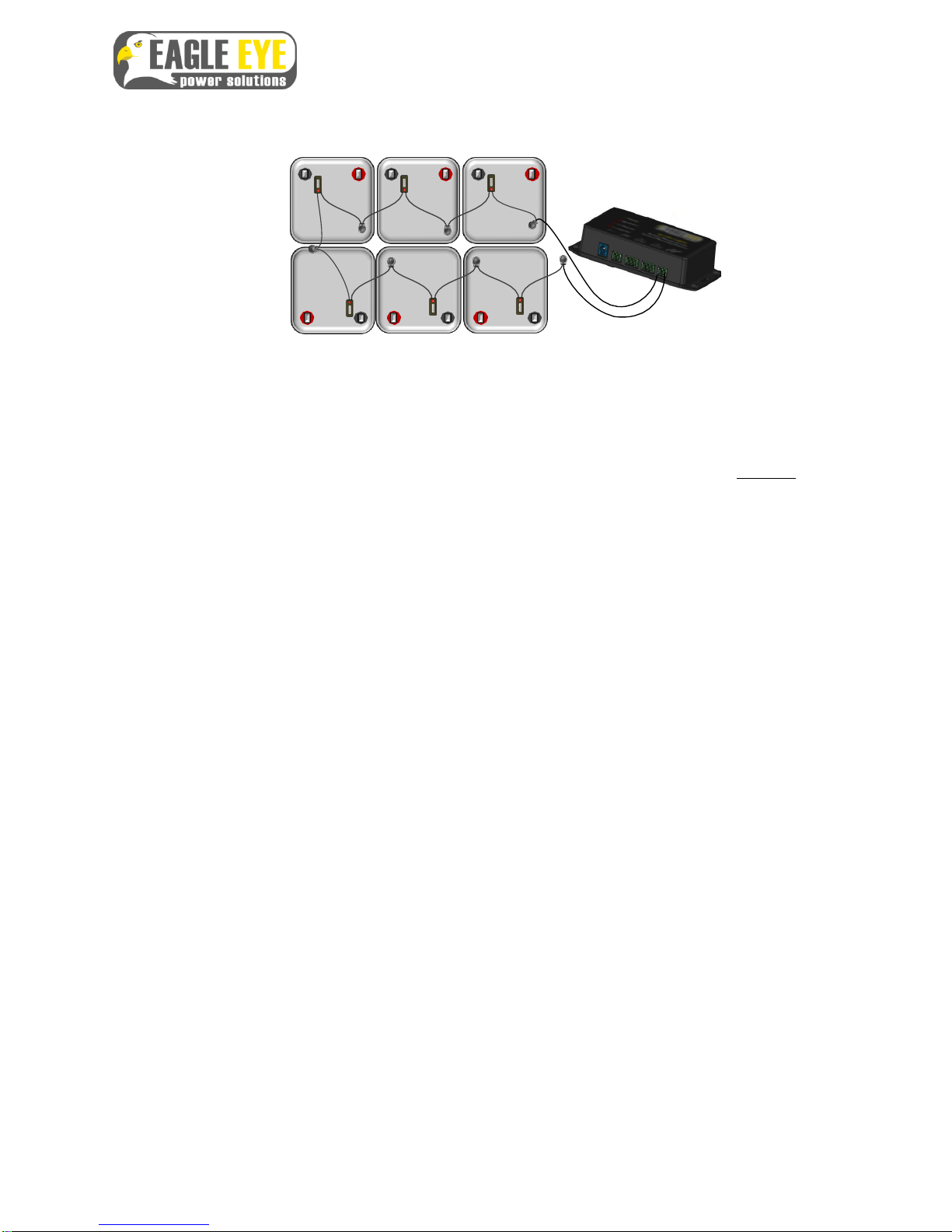

Each individual cell, monobloc or jar must have a sensor attached, to detect the

temperature of the unit. The sensors are connected in series, one wire of the sensor being

connected to a wire of the adjacent sensor.

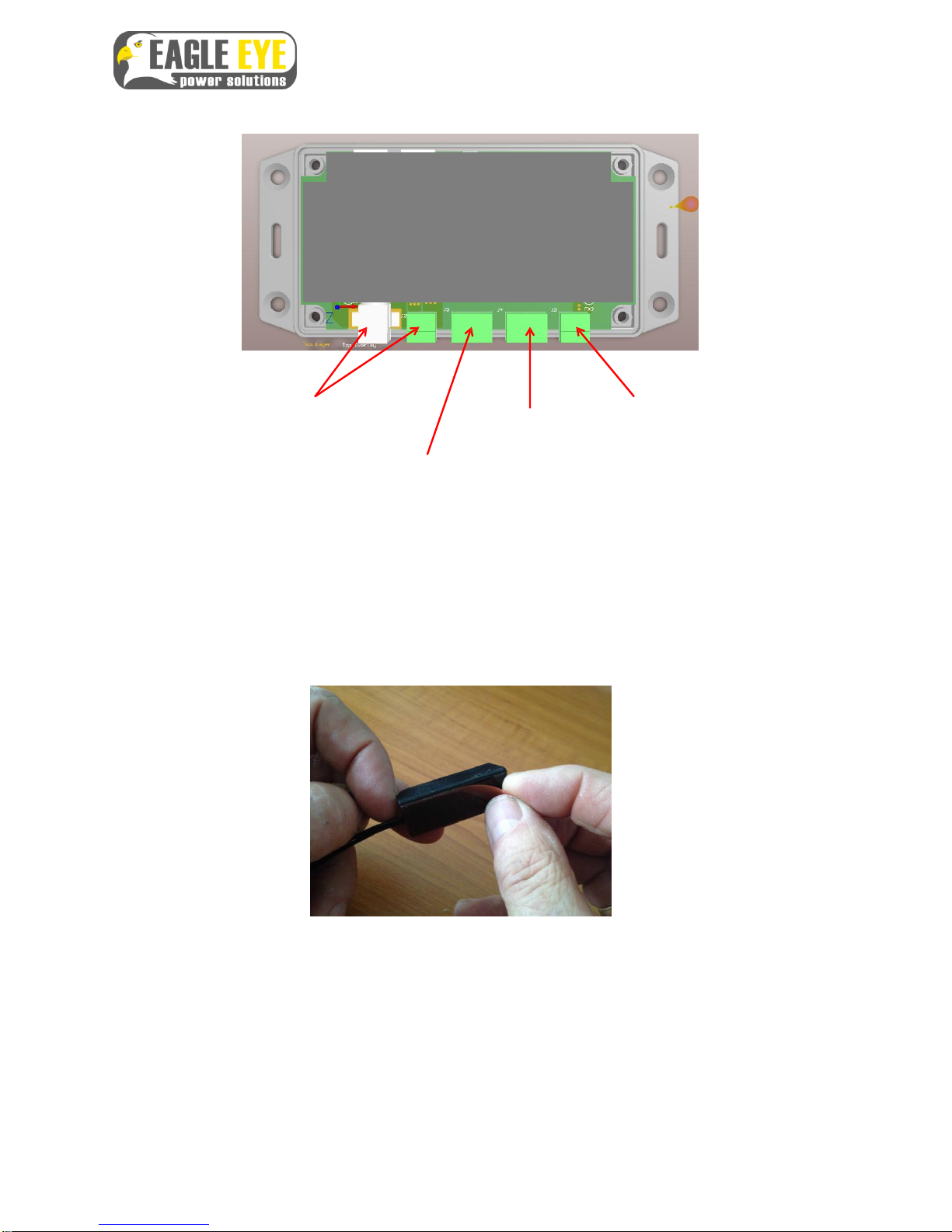

The connector (above) is an Insulation Displacement Connection (IDC), gel-filled for

protection against corrosive atmosphere and Lloyds approved as the equivalent of a

soldered joint for adverse environments.

Apart from securing the neat wall mounted monitor, the entire installation may be carried out

with a small screwdriver and a pair of side-cutting pliers. Interconnections typically take

less than 20 seconds each. Longer interconnections, such as shelf to shelf and rack to rack

are simple to accommodate with standard 20SWG cable, and the IDC connectors provided;

cable lengths, within reason, are not sensitive. Sensor installation for a 40-jar battery will

typically take less than an hour. Several batteries in the vicinity of each other may be

connected in series to the same monitor. As the system is completely electrically isolated

from the battery, voltages and polarities are not an issue.

Once the sensors are connected, the two end wires are brought back to the system

monitor and connected to the two connectors in the system monitor marked ‘Sensors’.